Method for installing and using moisture-proof pad

A moisture-proof mat and sound-insulating layer technology, applied in the direction of separation methods, chemical instruments and methods, carpets, etc., can solve the problems of inconvenient installation, high cost, singleness, etc., and achieve the goal of improving dimensional stability, improving quality of life, and reducing noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

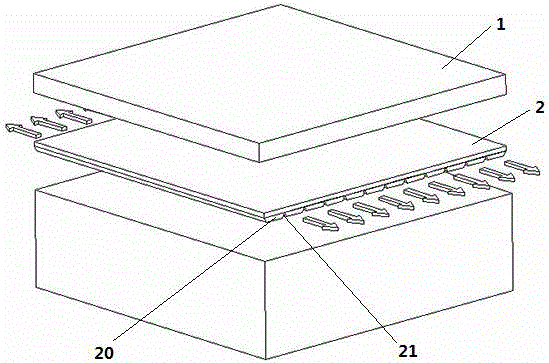

[0076] The minimum lateral distance between adjacent first sound insulation surfaces 21 between adjacent support units 20 is 0.5 mm; the distance between adjacent first sound insulation surfaces 21 of the same support unit 20 is 1 mm; The minimum distance between the surface and the intersection of the sound-insulating layer 1 and the first sound-insulating surface 21 is 0.3 mm. The minimum longitudinal distance between adjacent second sound-insulating surfaces 22 between adjacent supporting units 20 is 0.5 mm; the distance between adjacent second sound-insulating surfaces 22 of the same supporting unit 20 is 150 mm; the thickness of the sound-insulating layer 1 is 1.5 mm.

[0077] The sound insulation layer 1 adopts a fully open-pore EPDM foam sponge layer, and the supporting layer adopts a half-open-pore PVC foam material layer.

[0078] When installing and using, take the following steps:

[0079] 1 Make sure the ground is flat and level, clean and dry;

[0080] 2 Turn th...

Embodiment 2

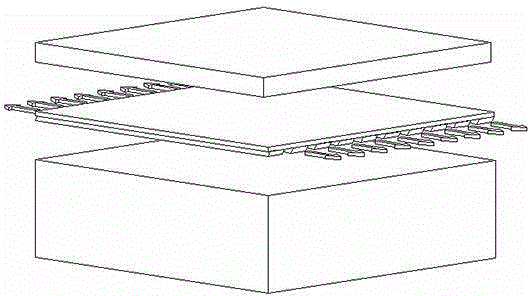

[0095] The minimum lateral distance between adjacent first sound insulation surfaces 21 between adjacent support units 20 is 500 mm; the distance between adjacent first sound insulation surfaces 21 of the same support unit 20 is 1000 mm; the surface of the support unit 20 farthest from the sound insulation layer 1 The minimum distance from the intersection of the sound insulation layer 1 and the first sound insulation surface 21 is 39mm.

[0096] The minimum lateral distance between adjacent first sound-insulating surfaces 22 between adjacent supporting units 20 is 500 mm; the distance between adjacent first sound-insulating surfaces 22 of the same supporting unit 20 is 1000 mm; the thickness of the sound-insulating layer 1 is 40 mm.

[0097] The sound insulation layer 1 adopts a closed-cell IXPE layer, and the supporting layer adopts a closed-cell polyethylene modified sound-proof material layer.

[0098] The preparation method of polyethylene modified sound insulation materi...

Embodiment 3

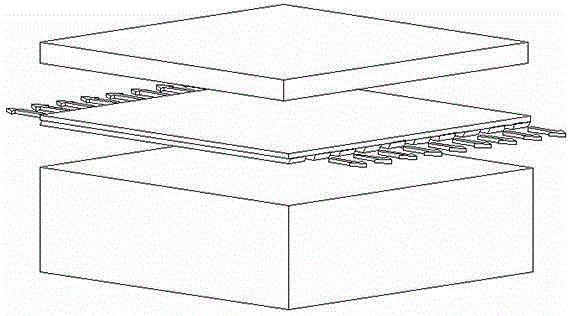

[0108] The minimum lateral distance between adjacent first sound insulation surfaces 21 between adjacent support units 20 is 10 mm; the distance between adjacent first sound insulation surfaces 21 of the same support unit 20 is 50 mm; the surface of the support unit 20 farthest from the sound insulation layer 1 The minimum distance from the intersection of the sound insulation layer 1 and the first sound insulation surface 21 is 10mm.

[0109] The minimum lateral distance between adjacent first sound-insulating surfaces 22 between adjacent supporting units 20 is 200 mm; the distance between adjacent first sound-insulating surfaces 22 of the same supporting unit 20 is 500 mm; the thickness of the sound-insulating layer 1 is 30 mm.

[0110] The sound insulation layer 1 adopts a closed-cell polyethylene modified sound insulation material layer, and the supporting layer adopts a semi-open EPDM foamed sponge layer.

[0111] The preparation method of polyethylene modified sound insu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com