Workpiece micro shock excitation device and workpiece micro shock excitation method for vibration machining

A vibration excitation device and vibration processing technology, which is applied to metal processing machinery parts, metal processing equipment, fluids using vibration, etc., can solve the problems of inability to realize frequency modulation, monitoring, and simple structure and function of mechanical vibration table, so as to facilitate popularization , wide application range and high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

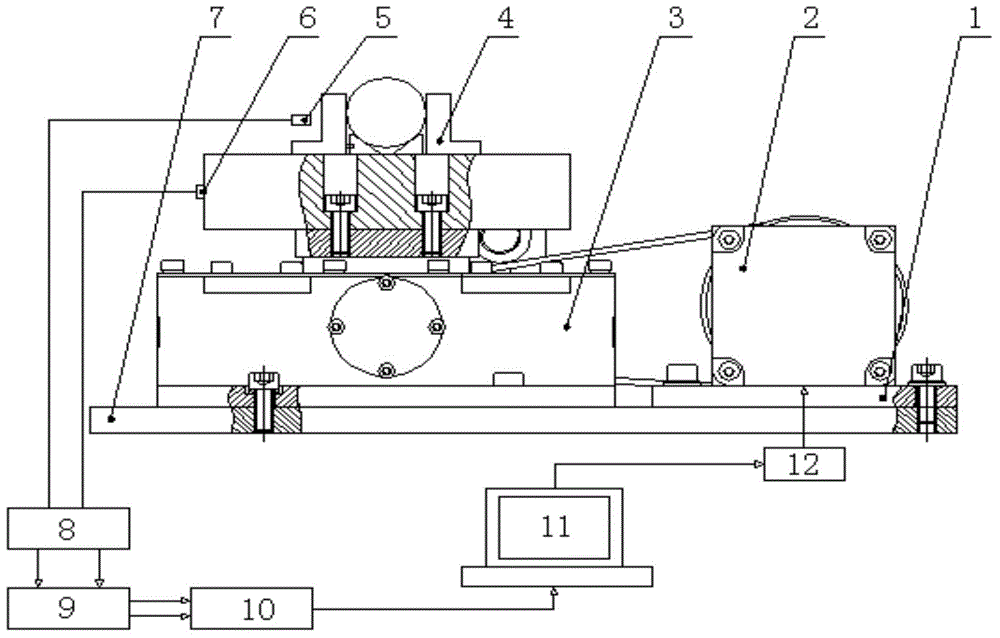

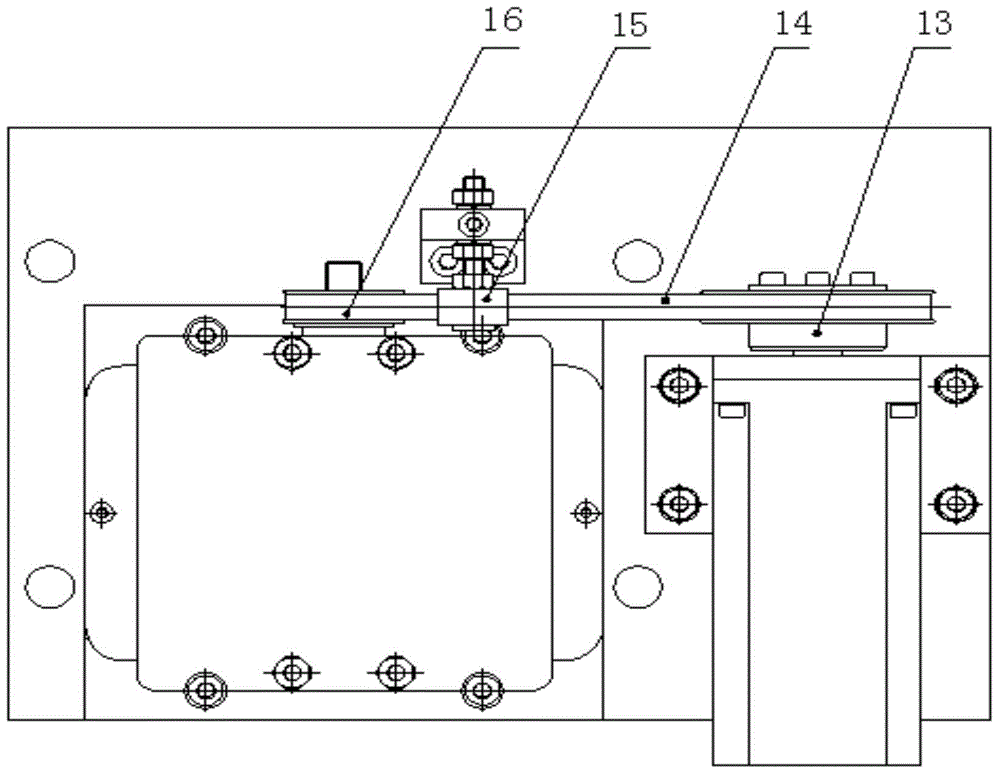

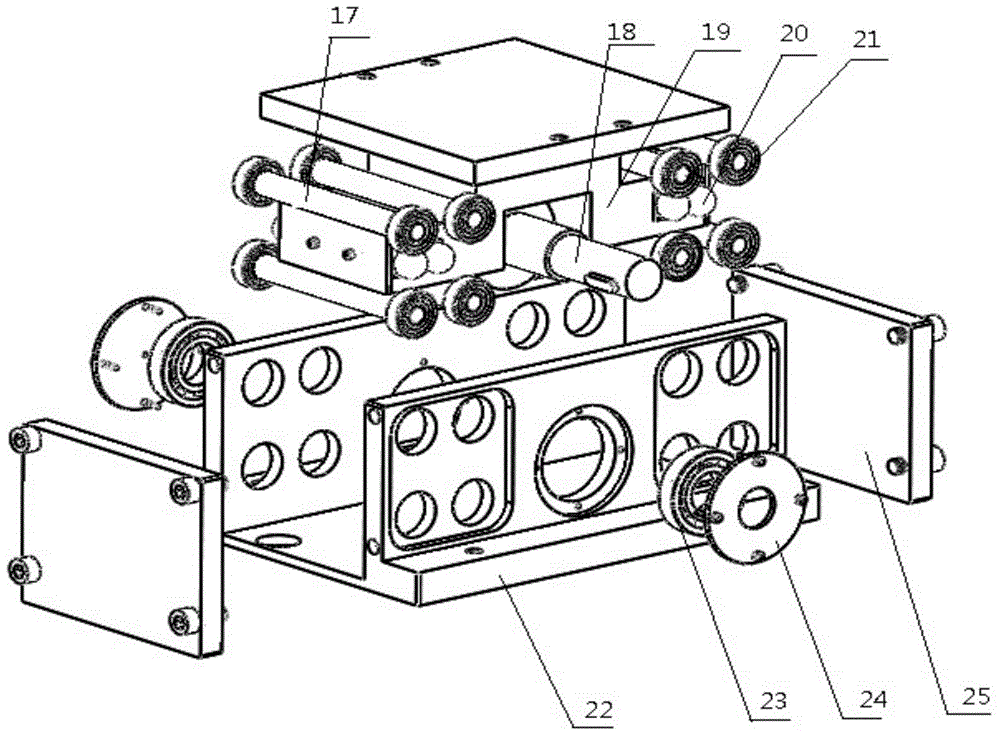

[0024] Such as figure 1 , figure 2 , image 3As shown, a workpiece micro-excitation device for vibration processing includes a motor mounting base 1, a servo motor 2, a vibration mechanism 3, a monitoring system, a fixture 4, a vibration excitation device bottom plate 7, a driving pulley 13, a timing belt 14, a Tightening mechanism 15 and driven pulley 16; Vibration mechanism 3 includes roller 17, eccentric wheel shaft 18, vibrating table 19, ball 20, roller deep groove ball bearing 21, support seat 22, eccentric wheel shaft deep groove ball bearing 23, eccentric Axle end cover 24 and box side plate 25; monitoring system includes laser displacement sensor 5, three-way force sensor 6, preamplifier 8, electrical signal conversion board 9, data acquisition card 10, industrial computer 11 and driver 12. The support base 22 is fixed on the bottom plate 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com