Titanium and titanium alloy low-cost continuous rolling technology and equipment

A technology of titanium alloy and rolling equipment, which is applied in the direction of metal rolling, can solve the problem of not carrying out substantive work, and achieve the effect of reducing the cost of preparation and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

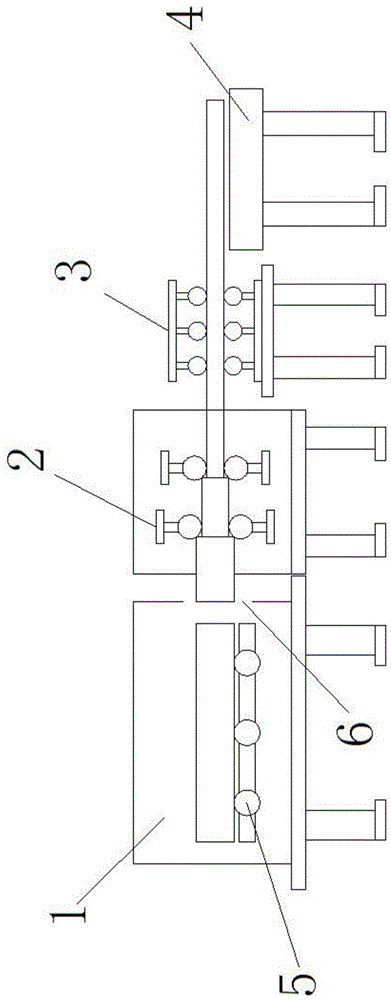

Image

Examples

Embodiment Construction

[0021] The invention provides a continuous rolling technology of titanium and titanium alloys, comprising the following steps:

[0022] a. Feeding: transport the titanium or titanium alloy ingot to the discharge track in the induction heating furnace;

[0023] b. Heating: When the titanium or titanium alloy ingot is transported to the discharge track in the induction heating furnace, the titanium or titanium alloy ingot is heated by electromagnetic induction by energizing the induction heating furnace;

[0024] c. Insulation conveying: transporting the heated pure titanium or titanium alloy ingot in step a from the induction heating furnace to the rolling mill in the state of insulation;

[0025] d. Rolling: use a rolling mill to continuously roll the pure titanium or titanium alloy ingots that are transported in with heat preservation in step b;

[0026] e. Material discharge: The material that has been rolled continuously is transported from the rolling unit to the charging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com