Planetary gear type two-sided lapping/polishing machine

A double-sided grinding and gear-type technology, which is applied in the direction of grinding/polishing equipment, surface polishing machine tools, grinding machine tools, etc., can solve the problems of reduced yield rate of processed parts, labor and time-consuming, etc., and achieve uniform wear and improved service life , Guarantee the effect of long-term work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

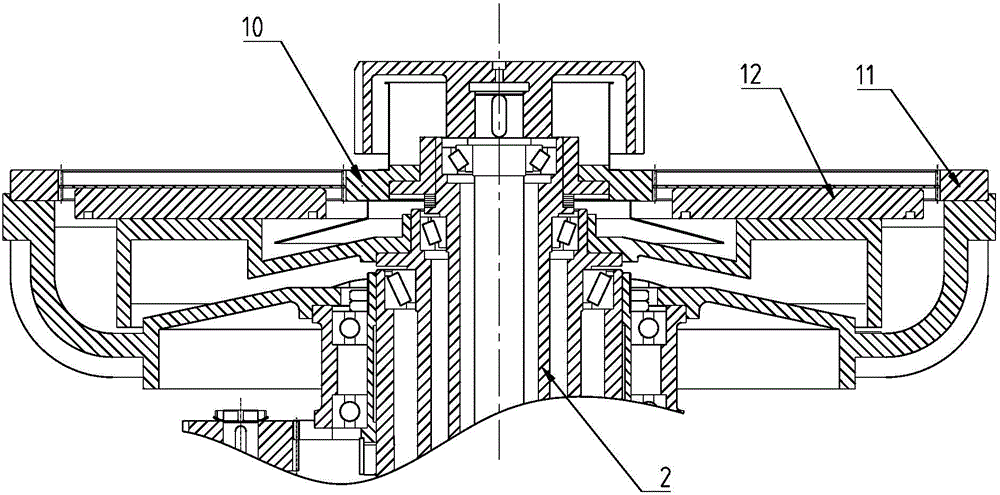

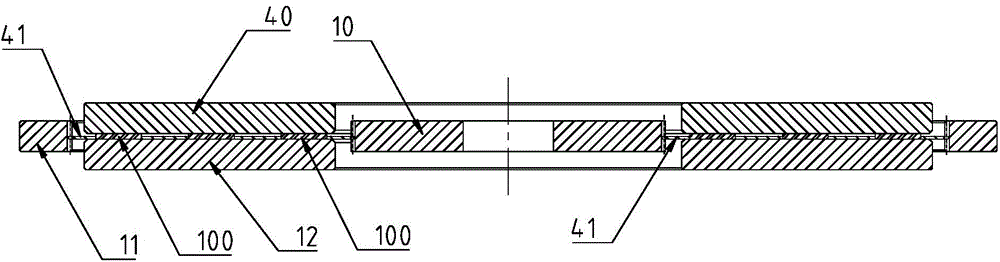

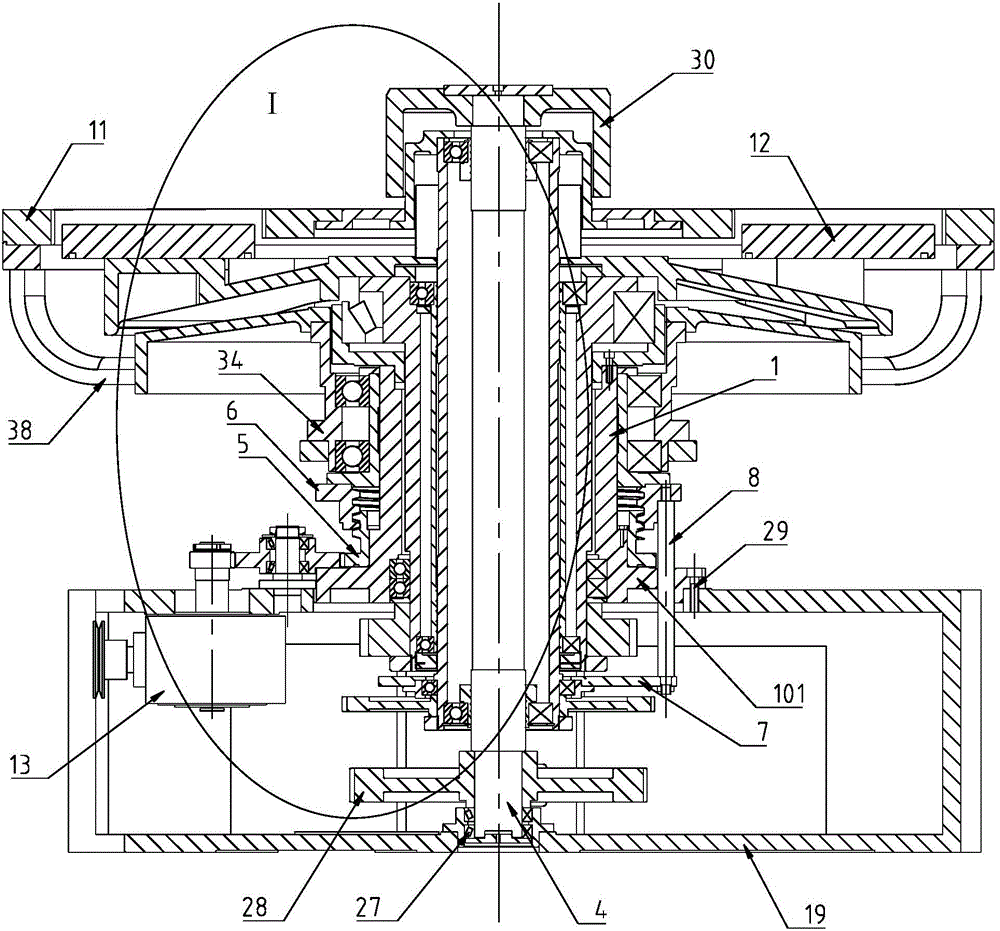

[0023] The structure of the planetary gear type double-sided grinding (polishing) machine of the embodiment of the present invention is as follows image 3 As shown, it includes frame, sun gear 10, ring gear 11, lower grinding disc 12, sun gear driving mechanism, inner ring gear driving mechanism, lower grinding disc driving mechanism, upper grinding disc driving mechanism, sun gear lifting mechanism and inner Ring gear lifting mechanism.

[0024] Frame comprises support 19 and the mounting base 1 that is fixed on the support 19, and mounting base 1 is hollow, and the bottom has mounting flange 101, and the flange 101 of mounting base is fixed on the support 19 with screw 29.

[0025] The sun gear lifting mechanism includes a lifting drive mechanism, a screw sleeve 5, a screw sleeve 6, a triangular supporting plate 7 and three pull rods 8.

[0026] The screw sleeve 5 is loosely fitted outside the mounting seat 1, and the lower end of the screw sleeve 5 is supported by the fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com