A double pendulum angle ultrasonic cutting device and method

An ultrasonic cutting, double swing angle technology, applied in metal processing and other directions, can solve the problems of inability to adjust the cutting angle of the tool in time, poor adjustability and adaptability, increase production costs, etc., and achieve strong adaptability and adjustable The effect of enhancing the performance and reducing the cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

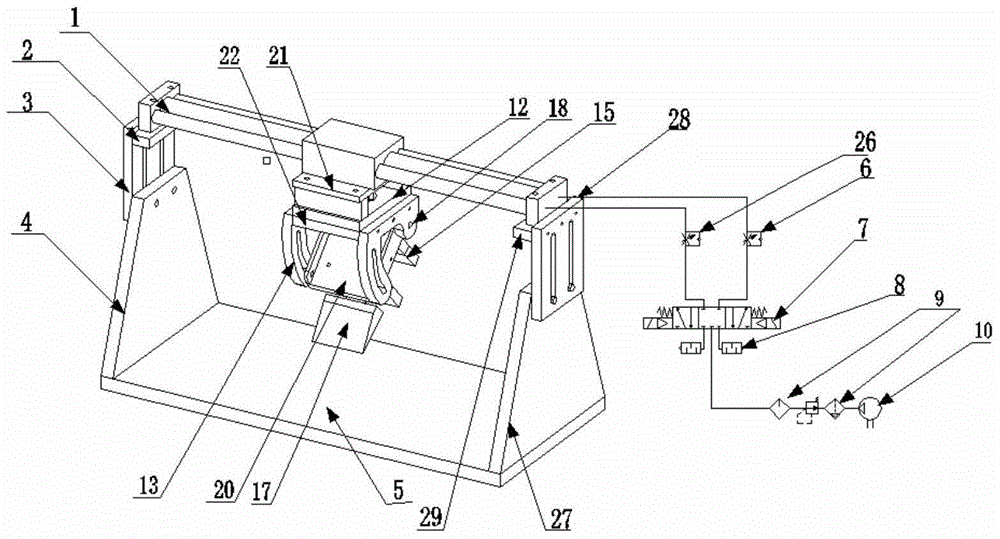

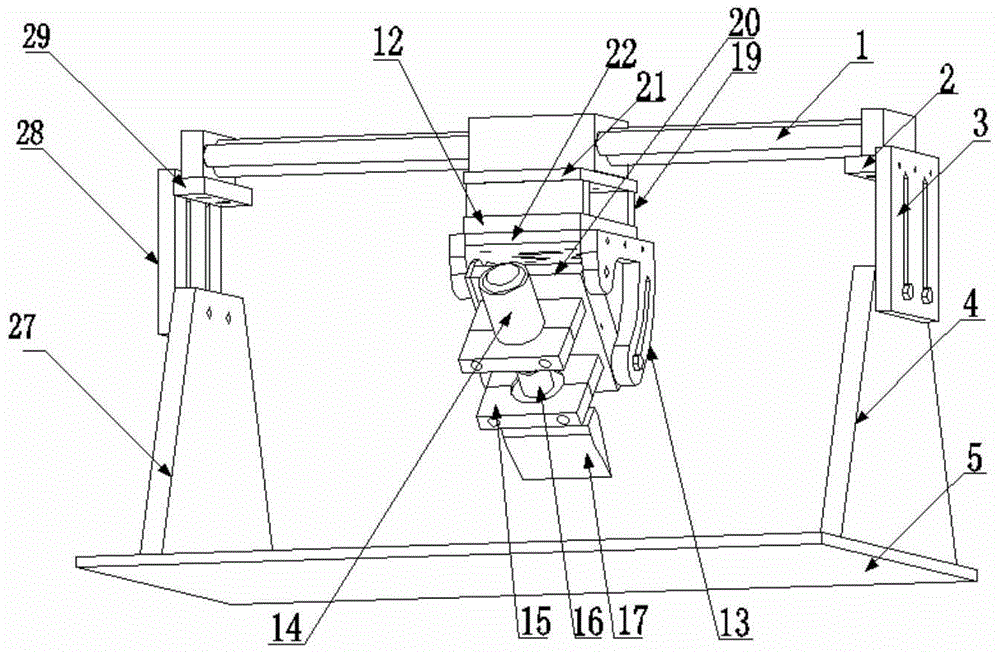

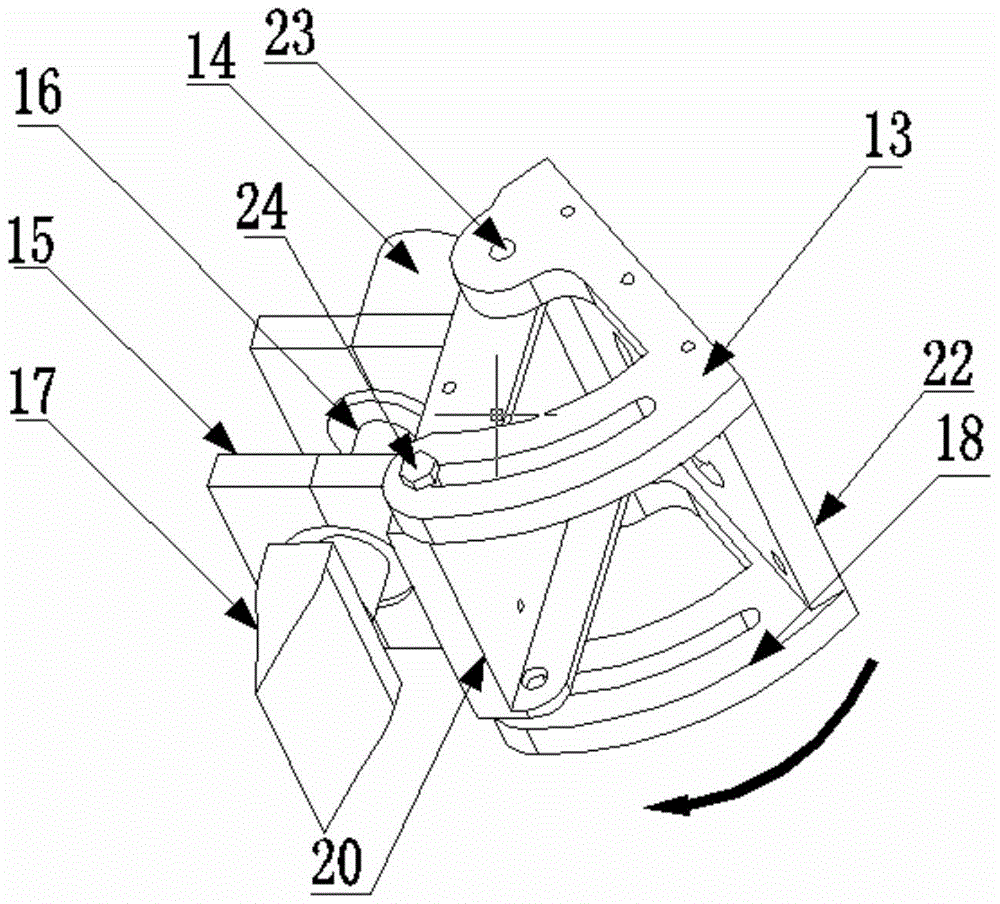

[0023] A dual-angle ultrasonic cutting device, comprising a bottom plate 5, screws, a first support plate 4, a first height adjustment plate 3, a first connecting plate 2, a rodless cylinder 1, a three-position five-way solenoid valve 7, a first single To throttle valve 6, the second one-way throttle valve 26, muffler 8, pneumatic triplet 9, pneumatic pump 10, bearing plate 21, second connecting plate 19, first horizontal swing angle plate 12, second level Swing angle plate 22, nut, first up and down angle plate 13, second up and down angle plate 18, connecting sleeve 23, third connecting plate 20, ultrasonic transducer 14, ultrasonic horn 16, tool holder 15, The ultrasonic cutter 17, the first bolt 24, the second bolt 25, the second support plate 27, the second height adjustment plate 28, and the fourth connection plate 29.

[0024] Such as figure 1 , figure 2 , image 3 As shown, the first support plate 4 and the second support plate 27 are vertically fixed on the bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com