Extruder screen changer

A technology of machine screen changer and screen changer, which is applied in the field of extruder screen changer, can solve the problems of easy leakage, complicated device manufacturing, high production cost, etc., to avoid production stoppage, compact device structure and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

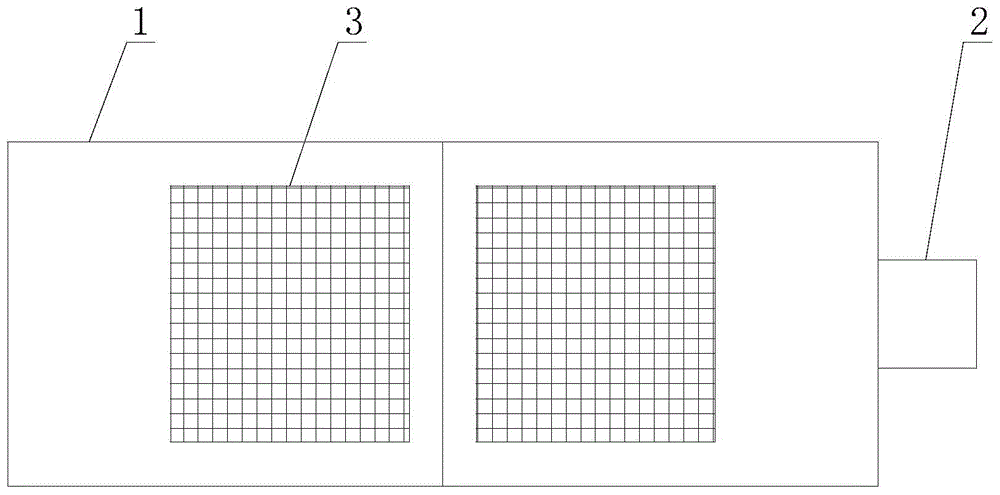

[0013] Such as figure 1 An extruder screen changing device shown includes a screen changer body, a slide plate 1 installed between the two panels of the screen changer body, and a hydraulic device 2 installed on one side of the slide plate 1 to push the slide plate 1 to move. There are two adjacent identical longitudinal square grooves, and a porous plate 3 with a filter screen embedded in the front end is installed in the longitudinal square grooves.

[0014] Further, the upper end of the perforated plate 3 is provided with a step for positioning.

[0015] In order to reduce the flow fluctuation, it is necessary to minimize the solid plate area between the two porous plates. Because the perforated plate does not need to be taken out from the front of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com