Method for preparing oriented porous silicon nitride ceramics based on gelatin solution freeze-drying technology

A technology of silicon nitride ceramics and gelatin solution, which is applied to ceramic products, other household appliances, household appliances, etc., can solve the problems of preparation failure, low solid phase content, green body collapse, etc., and achieves good hole connectivity and porosity. High, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

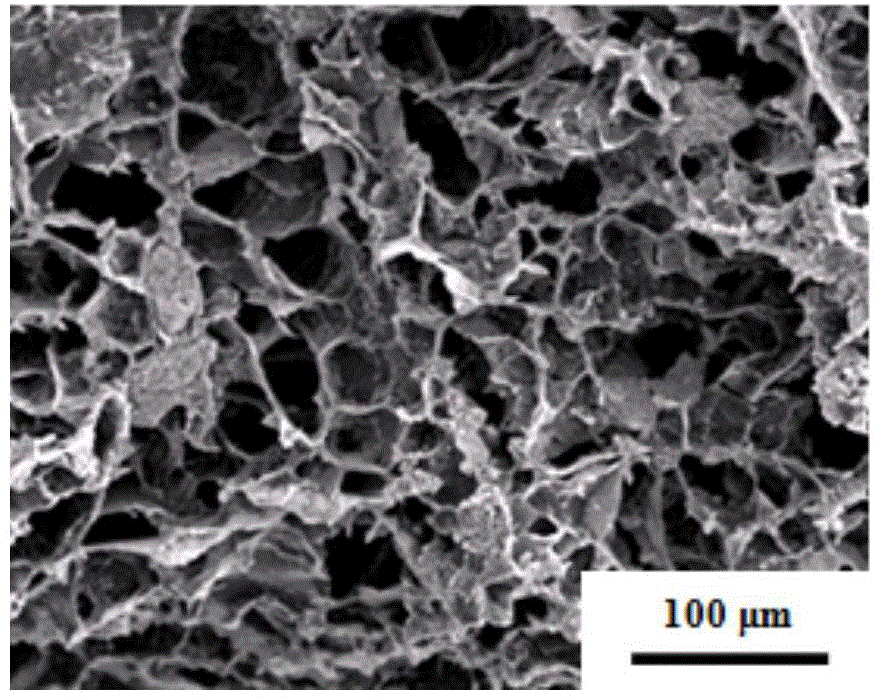

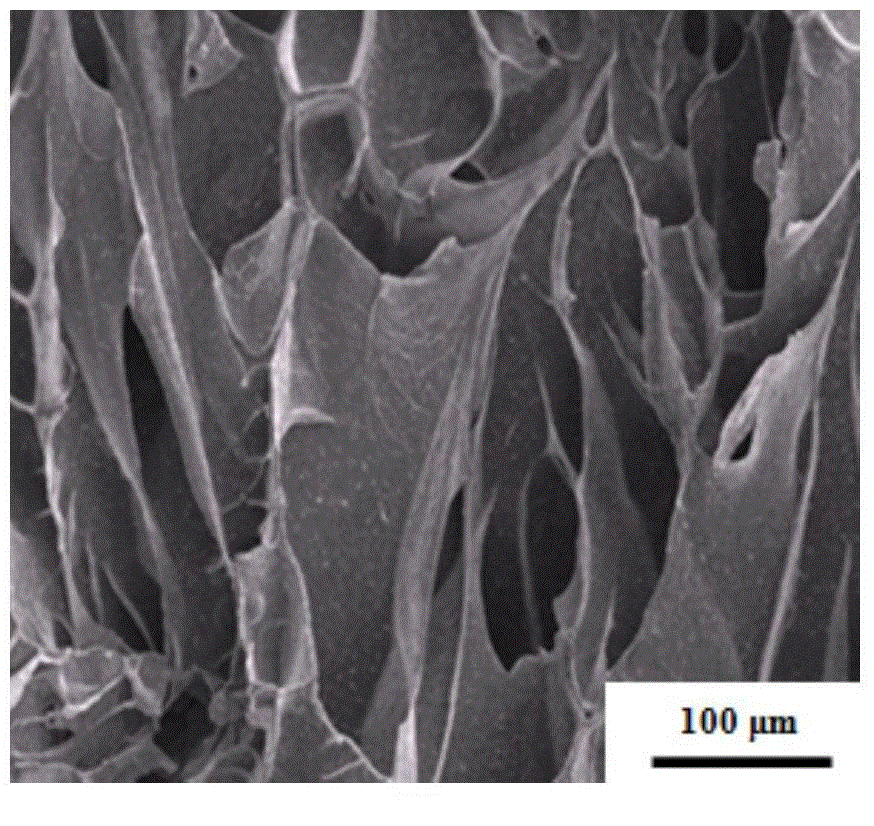

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

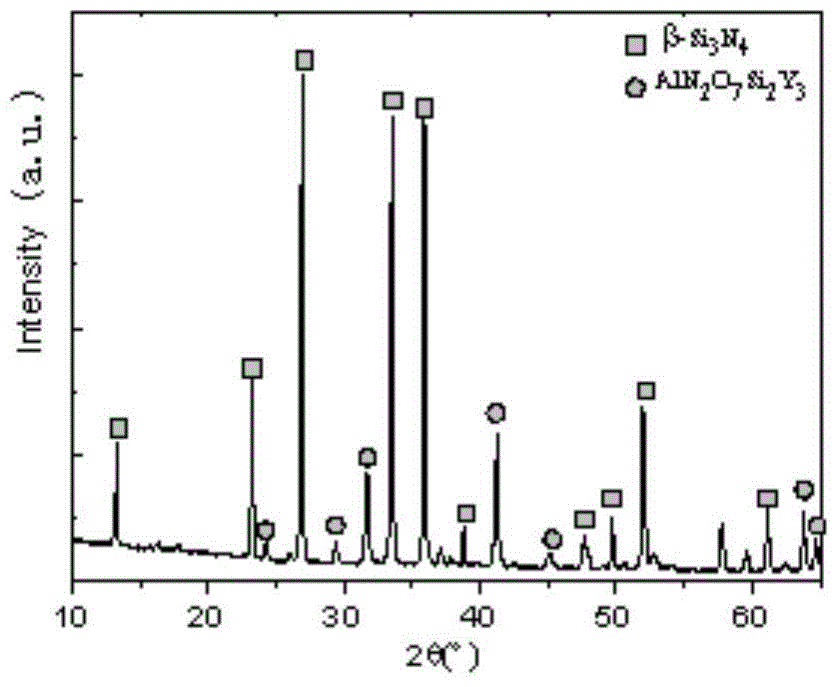

[0020] 1) One-dimensional oriented porous silicon nitride ceramics, the composition of which is shown in Table 1. In Examples 1 to 10 shown in Table 1, silicon nitride, yttrium oxide and aluminum oxide are mixed according to the proportions in Table 1. Put it into a ball mill tank, use absolute ethanol as the ball milling medium, and use agate balls to mill on a planetary ball mill for 5 hours, then take it out and put it in a drying oven at 80°C for drying, and the dried mixture will pass through a 14-mesh sieve to form a powder ;

[0021] 2) According to the ratio in Table 1, the gelatin was formulated into a gelatin solution and mixed evenly with the powder to form a homogeneous system, and placed in a vacuum box for vacuum defoaming;

[0022] 3) Place the defoamed homogeneous system in a refrigerator at 7°C for 2 hours to refrigerate the system to gel and obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com