Oil drilling pipe clamping jaw

A technology for oil drilling and pipe tools, which is applied to drilling pipes, drilling equipment, drill pipes, etc., and can solve problems such as low work efficiency, poor safety, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

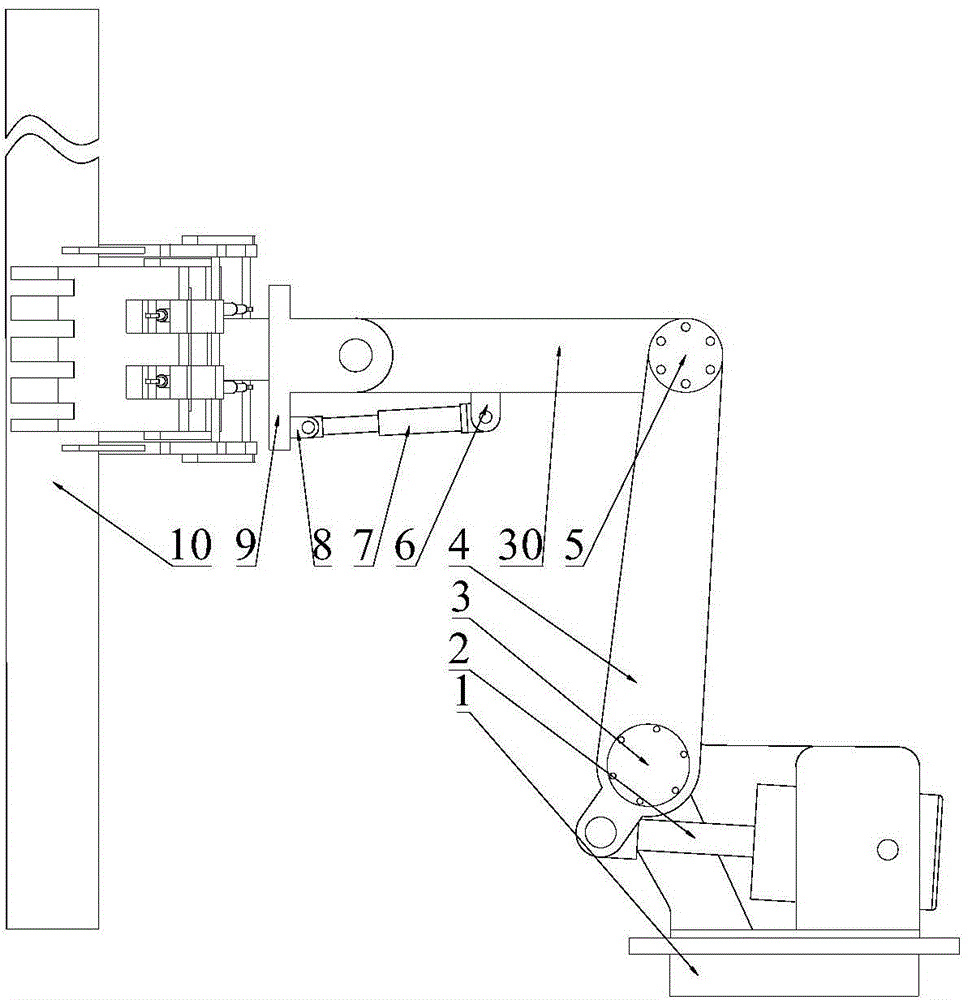

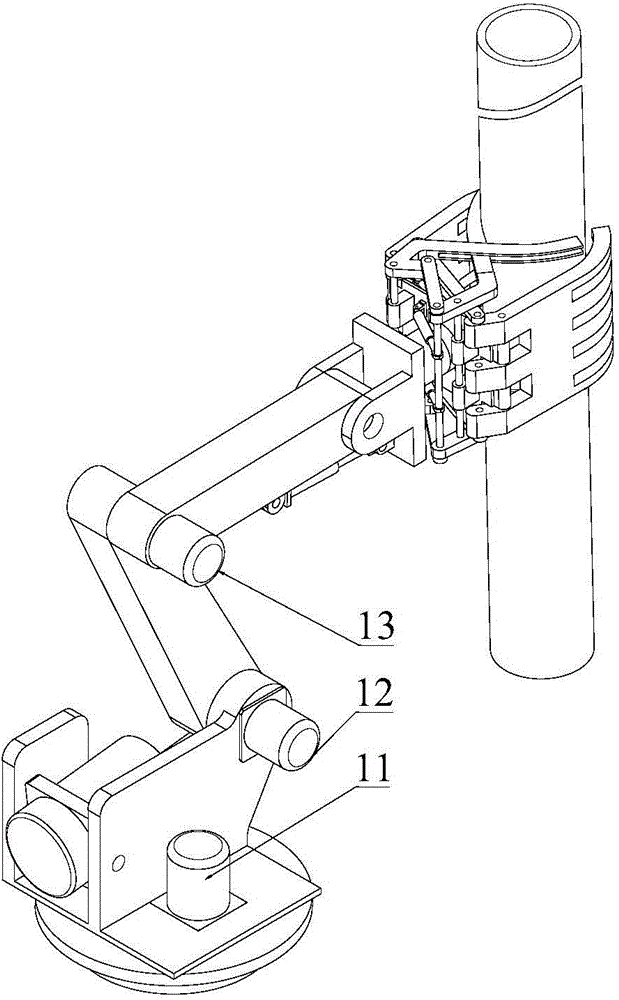

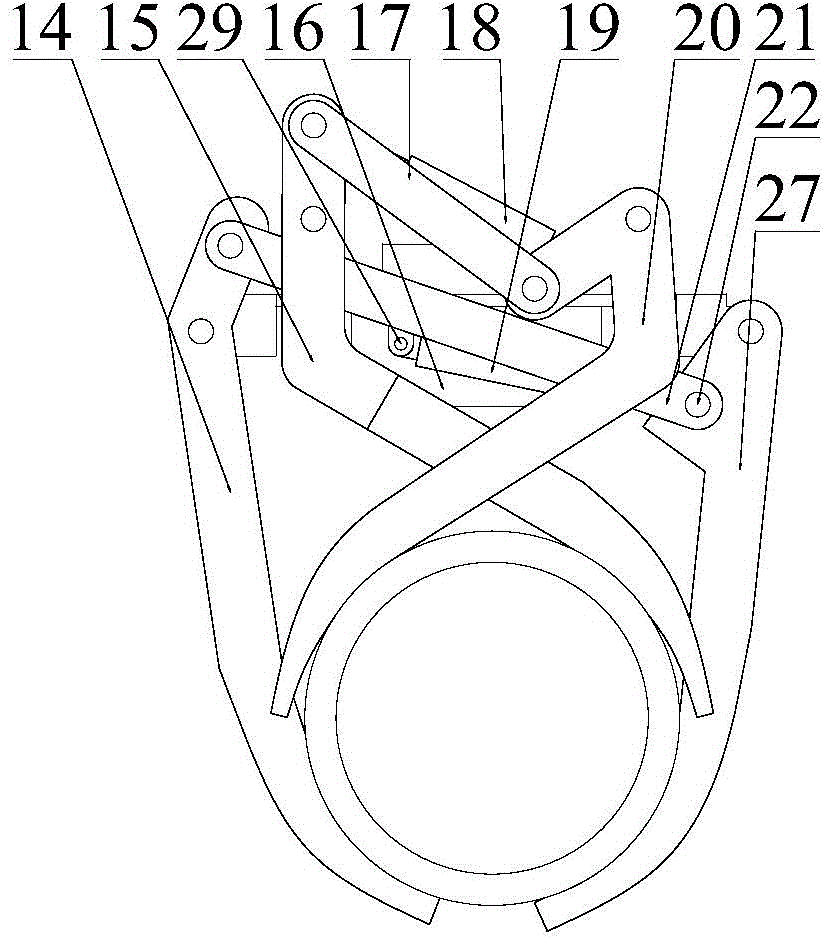

[0015] refer to figure 1 , figure 2 . Motor I (11) is installed on the pedestal (1), and pedestal (1) contains slewing bearing, when motor I (11) work, can drive whole jaw device to do horizontal plane rotary motion. One end of the balance cylinder (2) is connected to the base (1), and one end is connected to the main arm (4). The main arm (4) is installed on the base (1) and driven by the motor II (12), so that the main arm ( 4) It can move vertically within a certain range. One end of the small arm (30) is connected to the main arm (4) and driven by the motor III (13), so that the small arm (30) can move around the main arm (4). swing within a certain range. The other end of the forearm (30) is connected with the wrist (9), the support I (6) is installed on the forearm (30), the support II (8) is installed on the wrist (9), and the hydraulic cylinder I (7 ) is connected to the support I (6) at one end, and connected to the support II (8) at the other end. When the hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com