Measuring instrument positioning device suitable for high-altitude occasions

A technology of measuring instruments and positioning devices, which is applied in the directions of supporting machines, thermal development of materials, mechanical equipment, etc., can solve the problems that the accuracy of test data cannot be guaranteed, and achieve the effects of low cost, simple overall structure and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

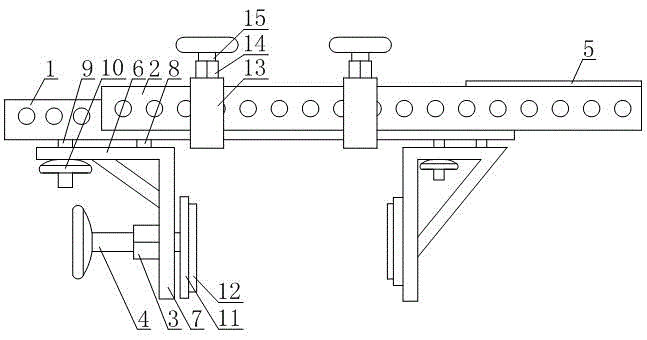

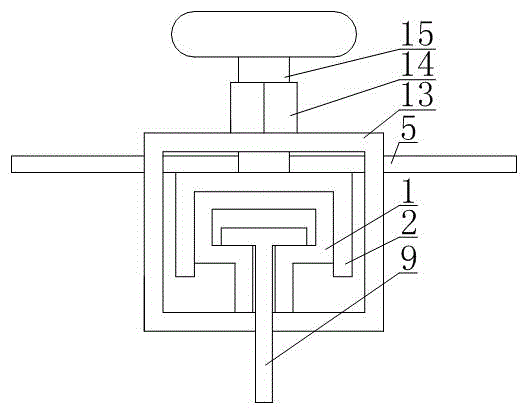

[0021] Such as figure 1 and figure 2 As shown, a measuring instrument positioning device suitable for high-altitude occasions includes a guide rail 1, a grooved mounting rail 2, a positioning plate 11, a positioning bracket and a track locking mechanism, wherein the guide rail 1 of this embodiment is provided with a The opening groove that the positioning bracket matches, the groove body of both the groove-shaped mounting rail 2 and the guide rail 1 of this embodiment open to the same side, the groove-shaped mounting rail 2 is sleeved on the guide rail 1 and is connected to the guide rail by a rail locking mechanism. Rail 1 is firmly connected. In the specific implementation of this embodiment, the track locking mechanism can be realized by bolts passing through the guide rail 1 and the grooved mounting rail 2 and nuts sleeved on the bolts, or screws can be used to connect the guide rail 1 and the grooved mounting rail 2 Lock and fix.

[0022] The positioning bracket of th...

Embodiment 2

[0025] This embodiment makes the following further limitations on the basis of Embodiment 1: in this embodiment, the bracket body of any one of the positioning brackets in the two positioning brackets is connected with a first internal thread column 3, and the first internal thread column 3 is parallel Arranged on the guide rail 1 , this embodiment is also provided with a first threaded adjusting rod 4 passing through the first internally threaded column 3 , and the external thread of the first threaded adjusting rod 4 matches the internal thread of the first internally threaded column 3 . In this embodiment, the positioning disc 11 connected with the positioning bracket of the first internal thread column 3 is specifically connected to the end of the first threaded adjustment rod 4, so that the position of the positioning disc 11 is convenient to be adjusted when the present embodiment is applied. fine-tuning. When this embodiment is applied, the first internal thread column ...

Embodiment 3

[0027]This embodiment makes the following further limitations on the basis of embodiment 1 or embodiment 2: in this embodiment, the side section shape of the groove body of the guide rail 1 is T-shaped, and the positioning guide block 9 is a T-shaped slider. In this way, when the present embodiment is applied, the guide rail 1 can be realized by using standard stainless steel or aluminum alloy profiles with T-shaped grooves, which is convenient for implementation. In order to prevent the positioning bracket from falling off easily when it slides to both ends of the guide rail 1, the opening at one end of the guide rail 1 can be sealed by welding in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com