Intelligent temperature regulation system and its application

A temperature-adjusting and intelligent technology, applied in the field of substations, can solve the problems of short operating life, cause death, large size, etc., and achieve the effect of simple installation method, convenient management and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

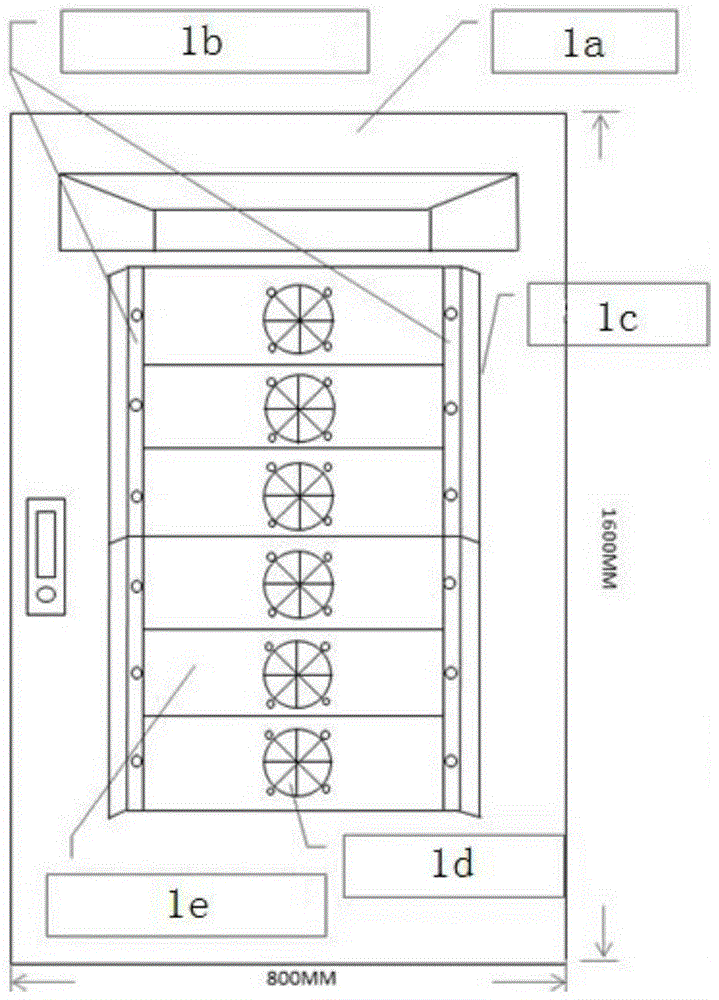

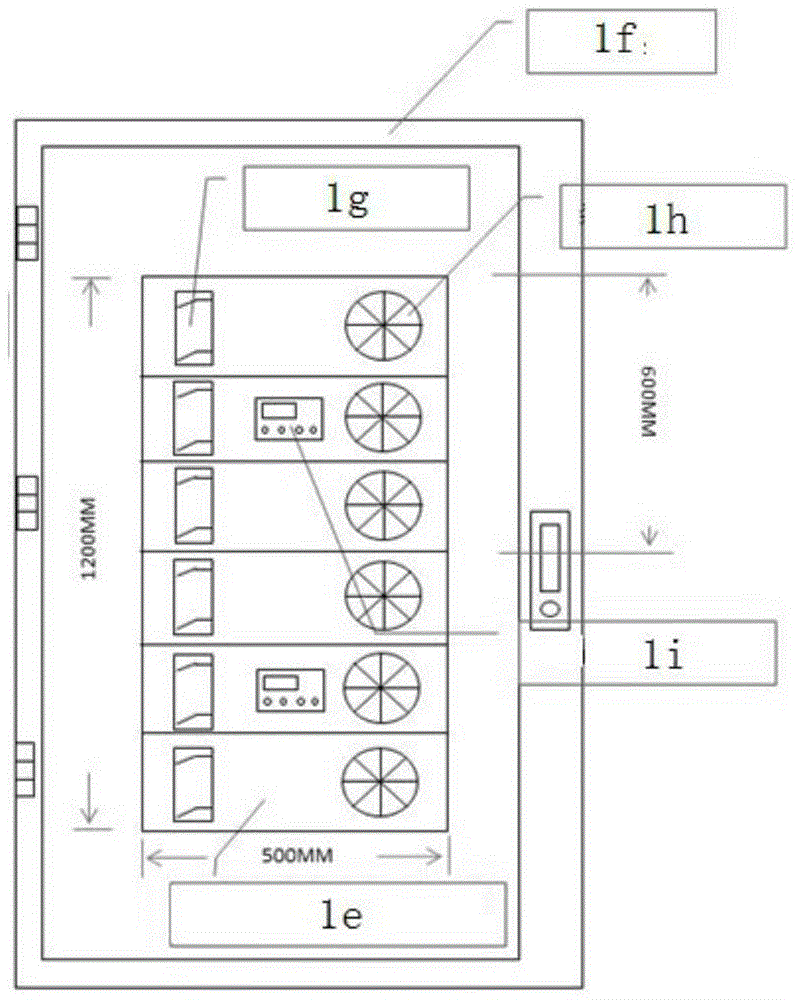

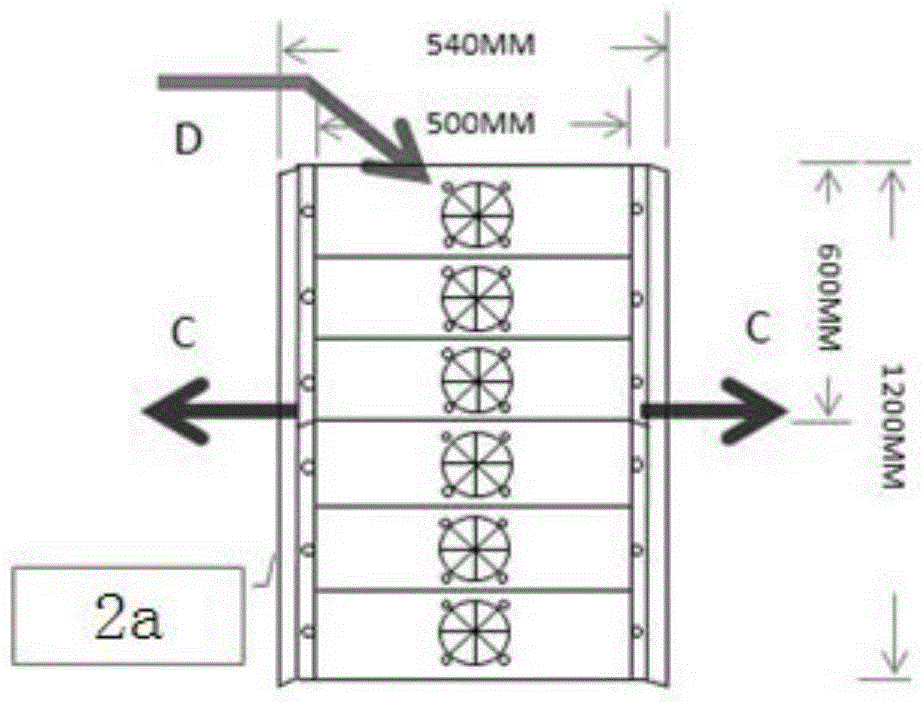

[0058] In order to better understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

[0059] As shown in the figure, the intelligent temperature adjustment system provided by the present invention is characterized in that it includes at least one intensive high-power semiconductor temperature adjustment block module 1, an internal circulation heat sink 2, an internal heat dissipation fan 3, and at least one phase change Heat exchange uniform temperature plate 4, a plurality of heat pipes that are sealed and pumped into a negative pressure state inside 5, at least one phase change radiator of the outer circulation miniaturized fin grid tube group 6, arranged in the outer circulation miniaturized fin grid tube Outer circulation radiator fan 7 and intelligent management circuit on the group phase change radiator 6;

[0060] Intensive high-power semiconductor temperature regulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com