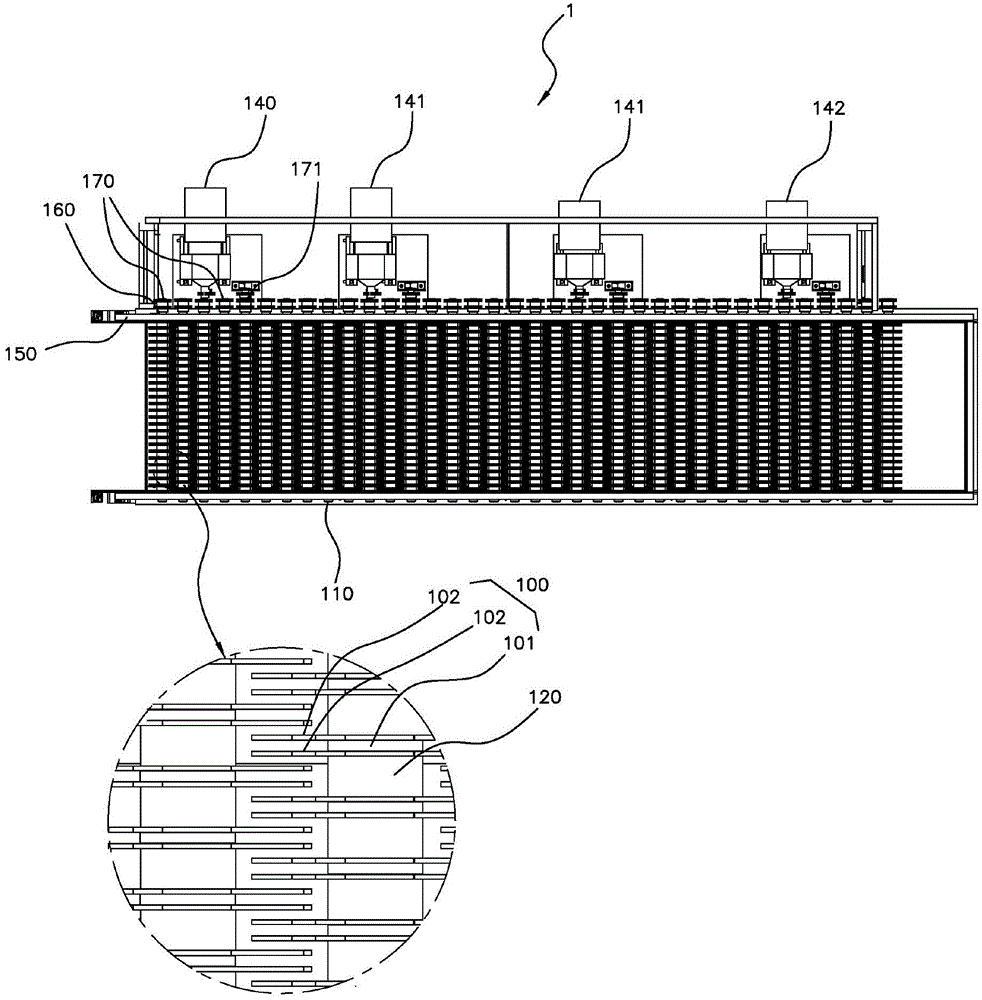

Double disc separator for separating out soil having high moisture content and apparatus for separating out soil by using same

A high moisture content, sorting device technology, applied in classification, solid separation, filtration, etc., can solve problems such as poor sand and soil sorting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

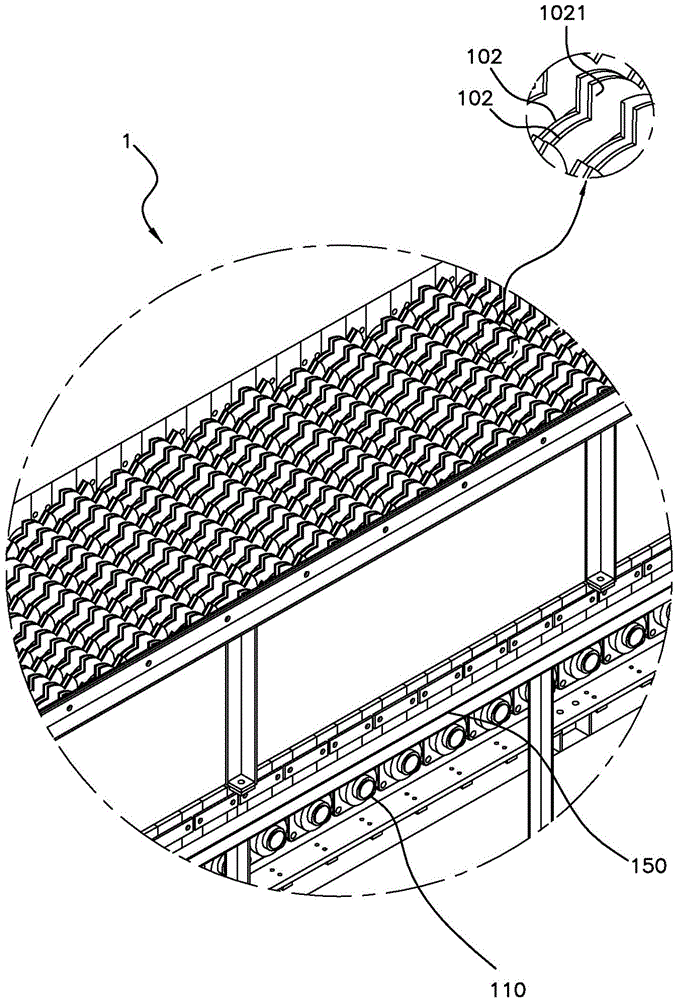

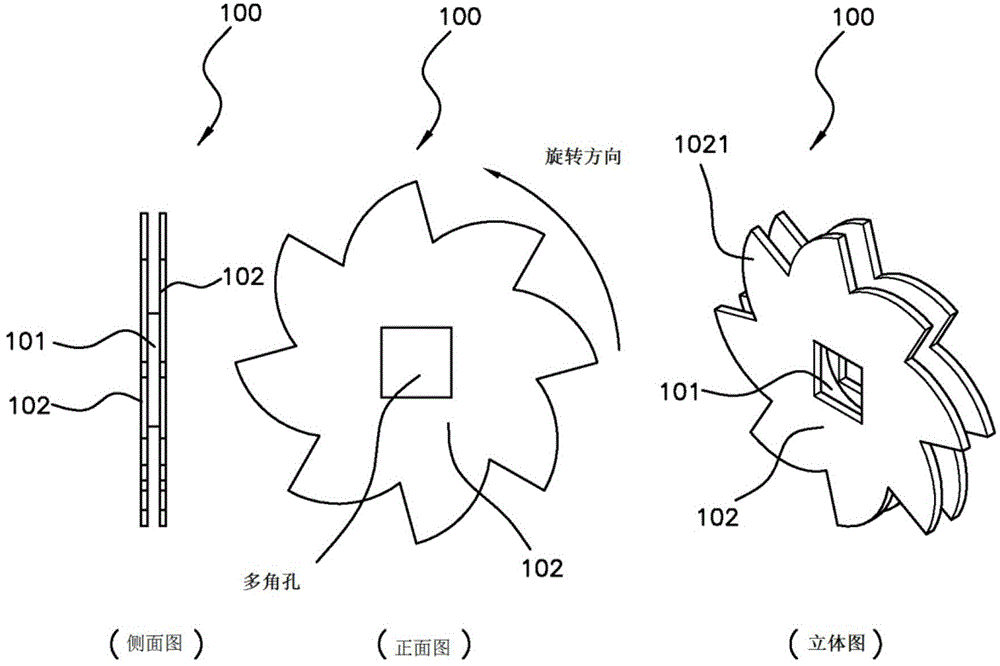

Method used

Image

Examples

Embodiment 1

[0111] When the inferior sand and soil are dropped into by heavy equipment, they are dropped in sequence through the inclination-angle-adjustable vibrating hopper 2 as a quantitative input device, and at the same time pass through the bar-shaped sieve 211 at the end of the vibrating hopper, thereby making it larger than the set specification (100mm) according to one embodiment. ) falls to the outside and is discharged, and the sand smaller than the set specification (100mm) is sorted, and the height of the sand that is too high is evenly spread through the feeding conveyor 3 and the disc sand crusher 4, and then put into To the double disc separator 1. In the double-disc separator 1, through the adjustment of the interval between the unit double discs, the sand smaller than the set specification (8mm) falls into the lower conveyor 5, and the sand larger than it is discharged. The double-disk separator 1 used at this time can also smoothly separate clay and sandy soil with high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com