Medium-frequency induction heating device of nuclear power main steam super pipeline mouthpiece

A nuclear power main steam and super pipeline technology, applied in the field of heating devices, can solve the problems of slow heating speed, high production requirements, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

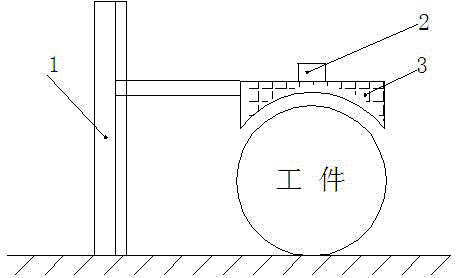

[0006] Such as figure 1 As shown, the intermediate frequency induction heating device locally heats the prefabricated hole of the workpiece, and uses the nozzle forming equipment (jack, press equipment, etc.) to manufacture the nuclear power main steam super pipeline nozzle. In the figure, the induction coil 2 and the temperature measuring device 3 heat the nozzle part. When the nozzle is preheated to the set temperature, the punch device is pushed out by the jack, and the mobile platform 1 in the intermediate frequency induction heating device moves up slowly. In the figure, the induction coil 2 and the temperature measuring device 3 continue to heat the nozzle until the ejection molding is completed.

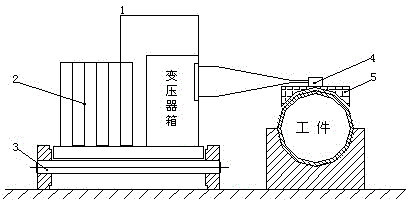

[0007] Such as figure 2 As shown, the heating device is composed of the induction heating power supply as the workpiece 1, the water cooling system as the workpiece 2, the mobile platform vehicle with height adjustment function as the workpiece 3, the induction coil as the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com