Fire-fighting inspection cabinet

A fire control and controller technology, applied in fire rescue and other directions, can solve the problems of delayed fire extinguishing, negligence in management, rust of pump shaft, impeller and shaft sleeve, etc., to achieve the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

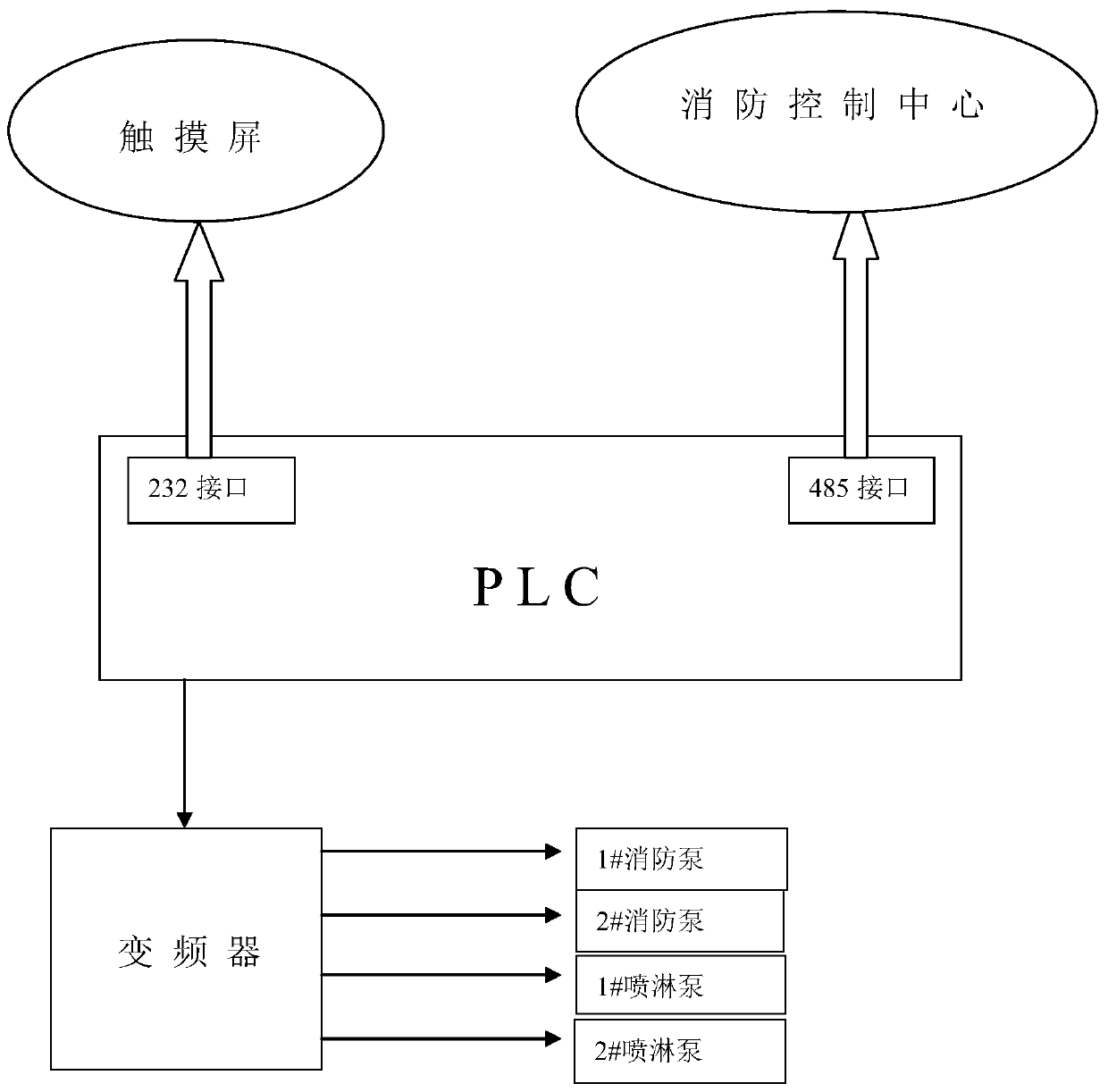

[0034] A fire inspection cabinet provided by a preferred embodiment of the present invention includes a programmable logic controller, the programmable logic controller is connected to the touch screen through the RS232 interface, connected to the fire control center through the RS485 interface, and the output terminal of the programmable logic controller Connect to the multi-function terminal of the frequency converter, set the multi-function terminal in the frequency converter as multi-speed function, and connect the fire pump and sprinkler pump; the frequency converter includes manual inspection mode and PID inspection mode; the manual inspection mode passes The up and down buttons adjust the output frequency of the inverter to control the speed of the fire pump and spray pump; the PID inspection mode uses a pressure transmitter installed on the pipeline to convert the pressure signal into a 4-20mA signal and input it to the inverter. Compared with the internal set pressure,...

Embodiment 2

[0041] Further: the frequency converter is composed of a rectification unit, a filter unit, an inverter unit, a brake unit, a drive unit, a detection unit and a micro-processing unit.

[0042] When working: the inverter adjusts the voltage and frequency of the output power supply by switching off the internal IGBT, and provides the required power supply voltage according to the actual needs of the motor, thereby achieving the purpose of energy saving and speed regulation. In addition, the inverter has many Protection functions, such as over-current, over-voltage, overload protection.

Embodiment 3

[0044]Further: the parameters set on the touch screen include the inspection cycle, and the inspection mode is automatically started by the cycle clock.

[0045] When working: Complete the low-frequency and low-speed self-propelled inspection control of the fire pump and spray pump. When a fire occurs, the programmable controller will automatically stop and interrupt the inspection program instantaneously after receiving the fire command, start the fire pump, and fire the fire. End shutdown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com