Multi-electrode single-side submerged arc welding method

A submerged arc welding and multi-electrode technology, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problem that the stress relief operation takes a lot of time, etc., and achieve the improvement of welding workability, excellent welding quality, and suppression of angular deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0151] Hereinafter, the effects of Examples falling within the scope of the present invention will be described in comparison with Comparative Examples deviating from the scope of the present invention.

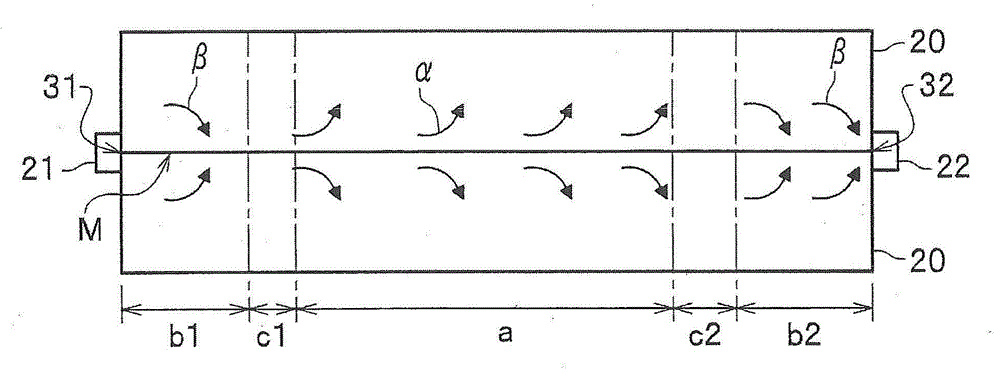

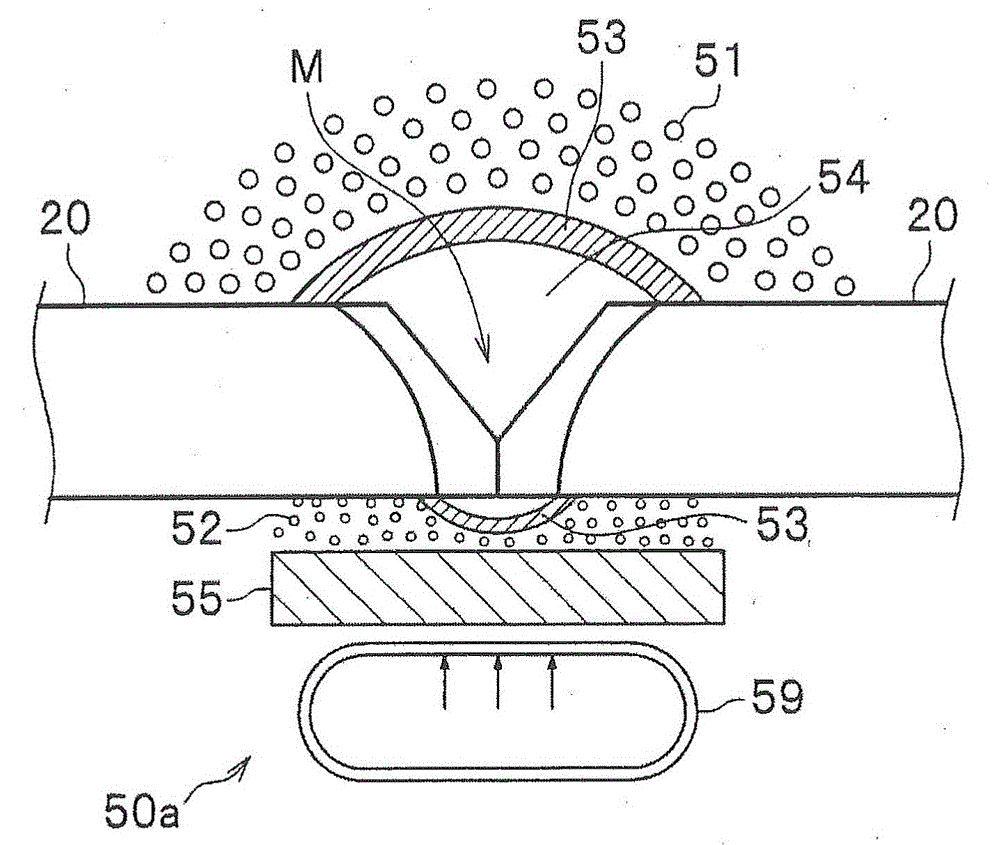

[0152] The two steel plates with the inclined surfaces formed on the end surfaces were butted so that the end surfaces faced each other, and a Y-shaped bevel was formed. The groove angle of the Y-shaped groove is 50°, the depth of the groove is 17mm, and the root gap is 0mm. In addition, the length of the steel plate is 20m, the thickness of the steel plate is 20mm, and the steel plate is DH36 steel plate certified by the marine class. This steel plate was welded.

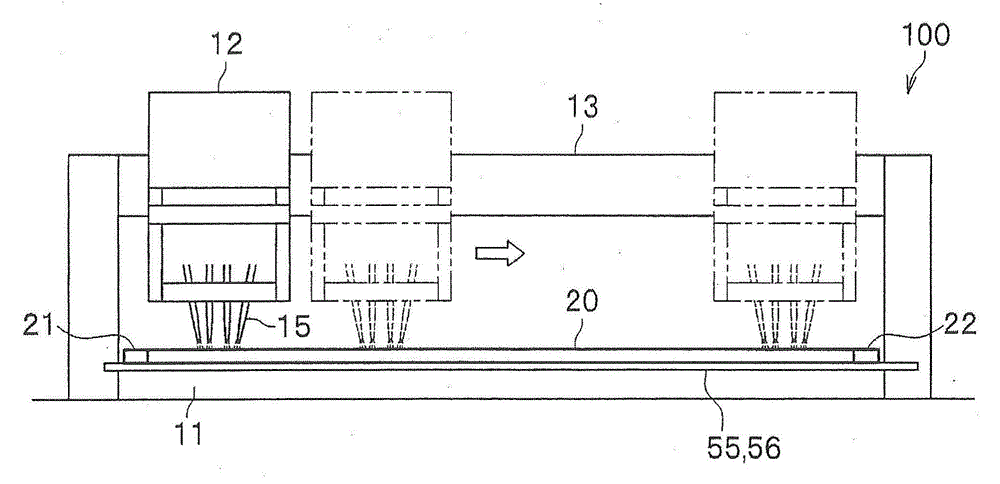

[0153] In this example, a welding device equipped with four electrodes was used. And, the conditions of the actual welding are set as the conditions shown in Table 1, the welding conditions of the welding start position and the joint start end are set as the conditions shown in Table 2, and the welding condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com