Fan housing bush assembling device

A technology of assembling device and fan cover, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low work efficiency and high labor intensity of workers, and achieve the effect of easy control, saving manpower and reducing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

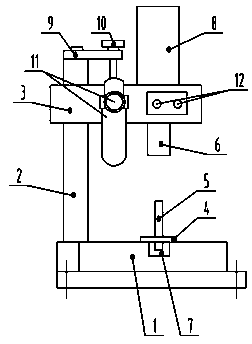

[0024] see figure 1 , in the figure, the fan casing bushing assembly device of the present invention includes a bracket, a support block 4, a support column 5 and a lifting sliding pressure block 6, wherein the bracket includes a base 1, a column 2 and a beam 3 connected in sequence, and the base is provided with Groove 7, the support block is fixed on the groove, the support column is fixed on the support block, the lifting sliding pressure block is set in the sliding groove on the beam, the lower part of the lifting sliding pressure block is facing the support column, and the lifting sliding pressure block is also driven mechanism.

[0025] The driving mechanism of the lifting sliding briquetting block is an air cylinder or hydraulic cylinder 8, wherein the cylinder body of the air cylinder or hydraulic ram is fixed on the beam, and the piston rod of the air cylinder or hydraulic ram is directly connected with the lifting sliding briquetting block. The top of the column is ...

Embodiment 2

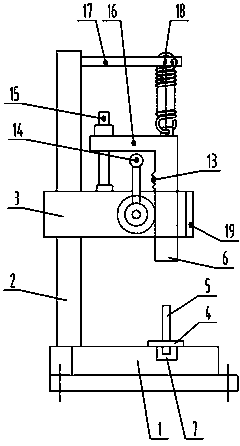

[0028] see figure 2 , in the figure, the structure of this embodiment is similar to that of Embodiment 2, and the same parts will not be repeated here. The difference is that the driving mechanism for lifting and sliding pressure blocks described in this embodiment includes a rack and pinion transmission mechanism 13 and an operating handle 14 , wherein the gear is installed in the beam through the rotation of the shaft, and a row of racks is arranged up and down on the side of the lifting sliding pressure block facing the gear installation, the gear and the rack are meshed for transmission, and the operating handle is fixedly installed on one end of the gear shaft.

[0029] A guiding mechanism and an automatic reset mechanism are provided at the top of the lifting and sliding pressure block. Described guide mechanism comprises guide rod 15, and guide rod is fixed on the crossbeam, and the top of lifting sliding pressure block is provided with flange 16, and wherein flange pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com