PVC protective film

A protective film and base film technology, applied in protective clothing, protective equipment, clothing, etc., can solve the problems of reduced viscosity, protective film adhesive layer peeling, ghosting, etc., to prevent and fall off, reduce peeling, and reduce residual glue Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

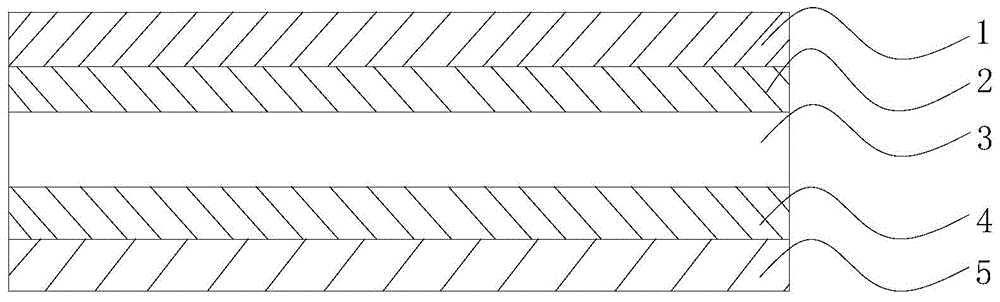

[0021] The following drawings further illustrate the technical solution of the present invention through specific implementation methods.

[0022] A PVC protective film, the PVC protective film includes a pressure-sensitive adhesive layer 1, a PVDC first isolation layer 2, a PVC base film layer 3, a PVDC second isolation layer 4, and a release agent layer 5 from top to bottom. Layer 1 is directly coated on the surface of the PVDC first isolation layer 2; wherein, the PVC base film layer 3 is a PVC base film layer added with a plasticizer, and the pressure-sensitive adhesive layer 1 is an auxiliary agent added with an absorbable plasticizer The thickness of the pressure-sensitive adhesive layer 1 is 2-6 μm, the thickness of the PVDC first isolation layer 2 and the PVDC second isolation layer 4 are respectively 2-5 μm, and the thickness of the PVC base film layer 3 is 20-60 μm , the thickness of the release agent layer 5 is 0.1-0.5 μm. The PVDC first isolation layer 2 is arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com