Construction technology for preventing cracking of exterior heat-insulation coatings and veneers

A construction technology and external thermal insulation technology, applied in covering/lining, construction, building structure, etc., can solve the problems of affecting the quality of wall thermal insulation, increasing construction costs, wasting financial and material resources, etc., to prevent and crack, and improve thermal insulation quality. , the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

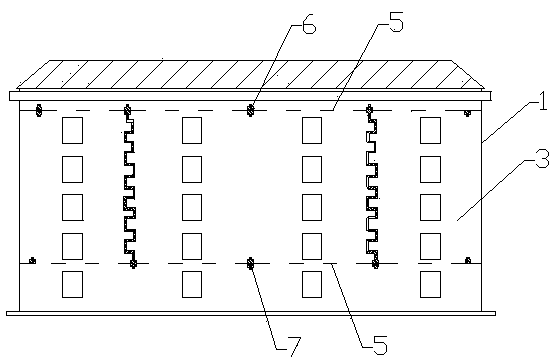

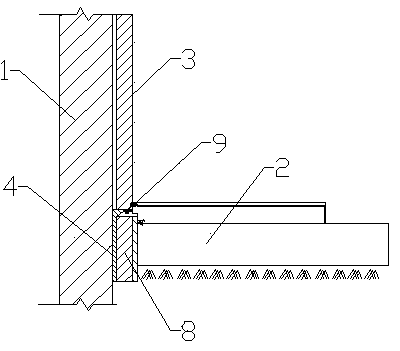

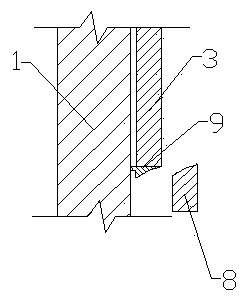

[0039] Examples such as Figure 1-4 As shown, a construction technique for preventing cracking of the external thermal insulation paint finish comprises the following steps:

[0040] A. Bottom control line

[0041] At the junction of the outdoor slope protection foundation 2 and the wall 1, stretch the horizontal control line around the building, which is the reference line for the construction of moisture-proof coils;

[0042] B. Polystyrene board insulation layer construction

[0043] Carry out insulation layer construction according to the basic sequence of popping doors and windows, vertical control lines, etc. → hanging datum line, sticking overturned mesh cloth → sticking polystyrene board → installing anchors → plastering mortar and laying mesh cloth;

[0044] In step B, the following processes are also included;

[0045] C. Keep the ventilation channel 5, install the suction and exhaust holes 6

[0046] 300mm below the window on the second floor of the building (th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com