Cylindrical mast lifting device and method

A lifting device and mast technology, which is applied in the direction of mast, transportation and packaging, and ship parts, etc., can solve the problems of mast lifting device collision, major property, loss, etc., and achieve the effect of manual lifting of the mast, which is light and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

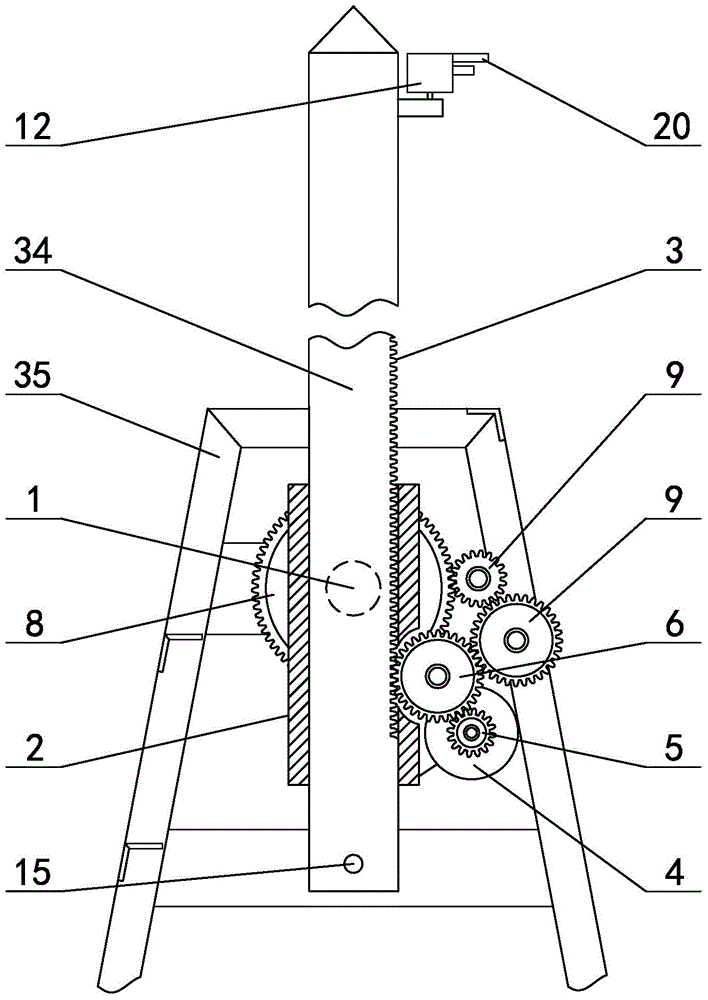

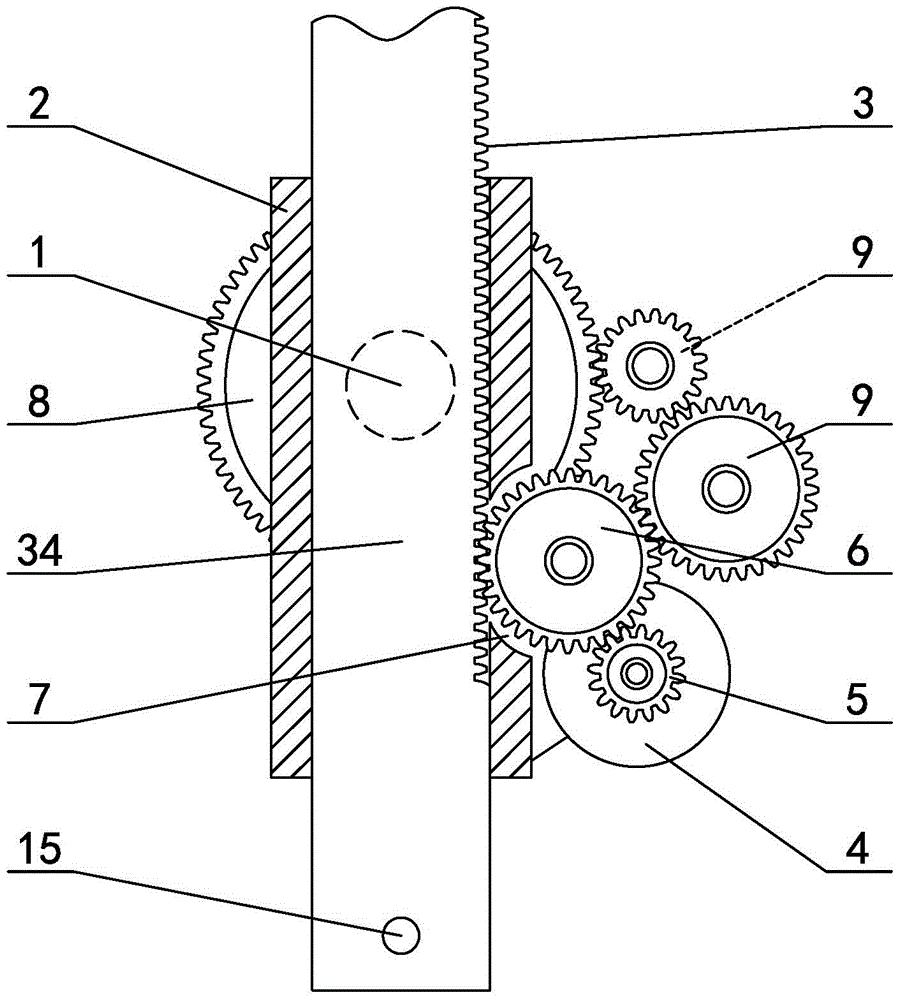

[0035] in such as figure 1 In the shown embodiment 1, a columnar mast lifting device, the columnar mast 34 is rotatably arranged on the mast base frame 35 of the ship, the mast base frame is a U-shaped structure with the opening facing upwards, the mast base A horizontal shaft 1 perpendicular to the direction of navigation of the ship is provided on the frame, and a sliding sleeve 2 for positioning the mast is fixed in the middle of the horizontal shaft. The rack 3, the outer wall of the sliding sleeve is provided with a mast motor 4 and a support 36 for fixing the transmission system (see Figure 4 ), the output shaft of the mast motor is provided with a mast drive gear 5, the mast drive gear meshes with a mast lifting gear 6, and a gap 7 is provided on the side wall corresponding to the sliding sleeve and the rack (see image 3 ), one side of the mast lifting gear meshes with the rack on the mast through the gap on the side wall of the sliding sleeve, the fixed gear 8 coaxi...

Embodiment 2

[0044] The swing mechanism of embodiment 2 (see Figure 6 ) includes a swing motor (not shown in the figure), the swing motor is a speed-regulating motor, the power shaft 21 of the swing motor is stacked with a forward drive gear 22 and a reverse drive gear 23, the forward drive gear and the reverse drive gear The driving gears are sector gears with the same number of teeth and the same modulus and are arranged in dislocation. The swing mechanism also includes a swing gear 24. The forward drive gear is intermittently meshed with the swing gear, and the reverse drive gear is intermittently meshed with the reversing gear 25. The gear is engaged with the swing gear, and the swing gear is engaged with the swing output gear 27 through a reduction transmission gear 26. When the forward drive gear is engaged with the swing gear, the reverse drive gear is disengaged from the reversing gear, and the reverse drive gear is engaged with the reversing gear. When the gears are engaged, the ...

Embodiment 3

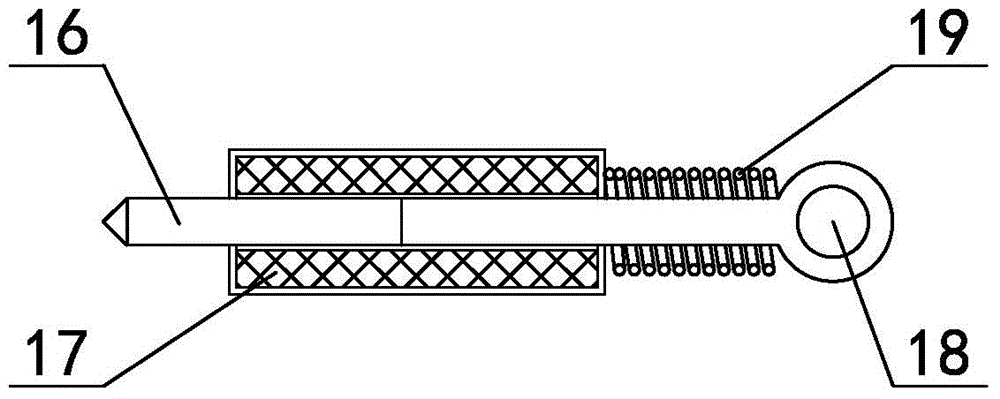

[0047] The mast top of embodiment 3 is provided with emergency anti-collision mechanism (see Figure 7 ), the emergency anti-collision mechanism includes a straight rod 28 and a compression spring 29, the length direction of the straight rod is parallel to the length direction of the ship, the straight rod is slidably worn on the mast, and the front end of the straight rod is provided with a bumper , the compression spring is sleeved on the straight rod, one end of the compression spring is in contact with the impact head, the other end is in contact with the mast, the rear end of the straight rod is provided with a limit plate 31 to prevent the straight rod from coming out, and the limit plate The end of the straight rod on the rear side is fixed with a stay cord 32, and the stay cord is connected with the draw ring through a pulley mechanism 33. The obstacle detection device of this embodiment is arranged below the straight rod; a clutch is provided between the mast motor an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com