Automatic feeding device for capacitors

A technology of automatic feeding and capacitors, applied in conveyor control devices, vibrating conveyors, transportation and packaging, etc., can solve the problems of capacitor guide pins falling to the ground, damage to capacitor guide pins, and damage to the quality of capacitor guide pins. The effect of reducing physical damage and increasing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

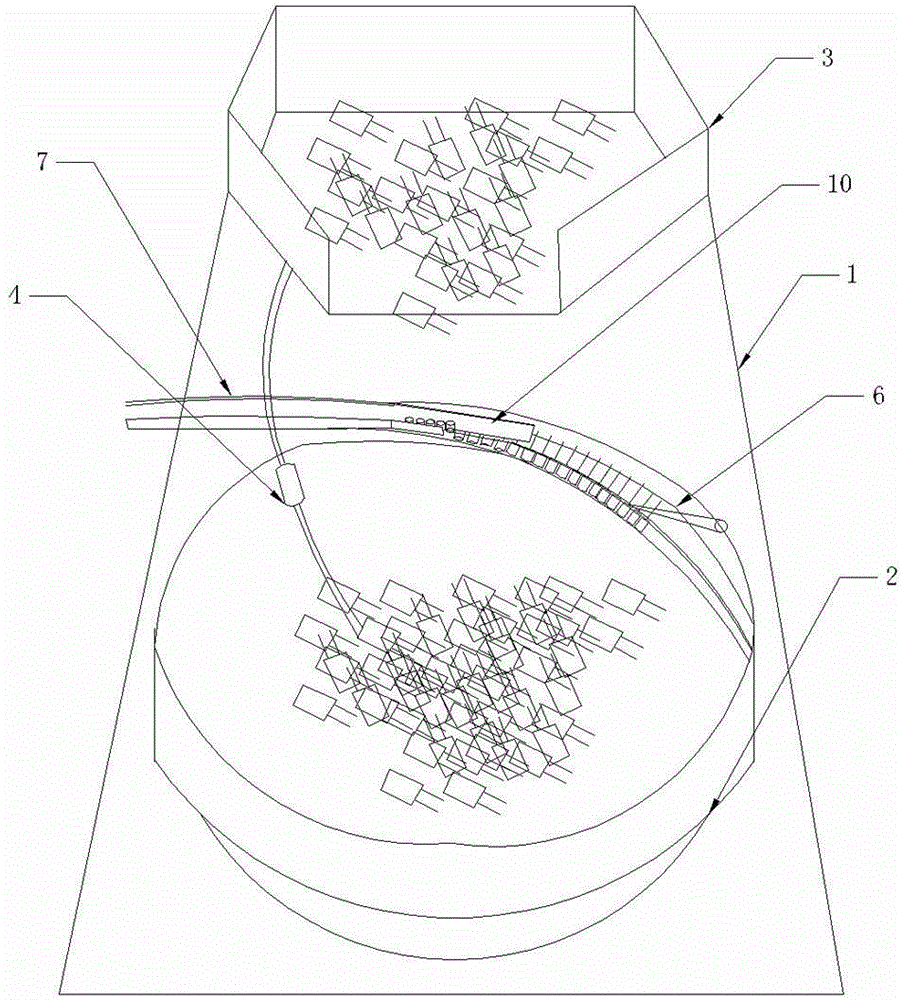

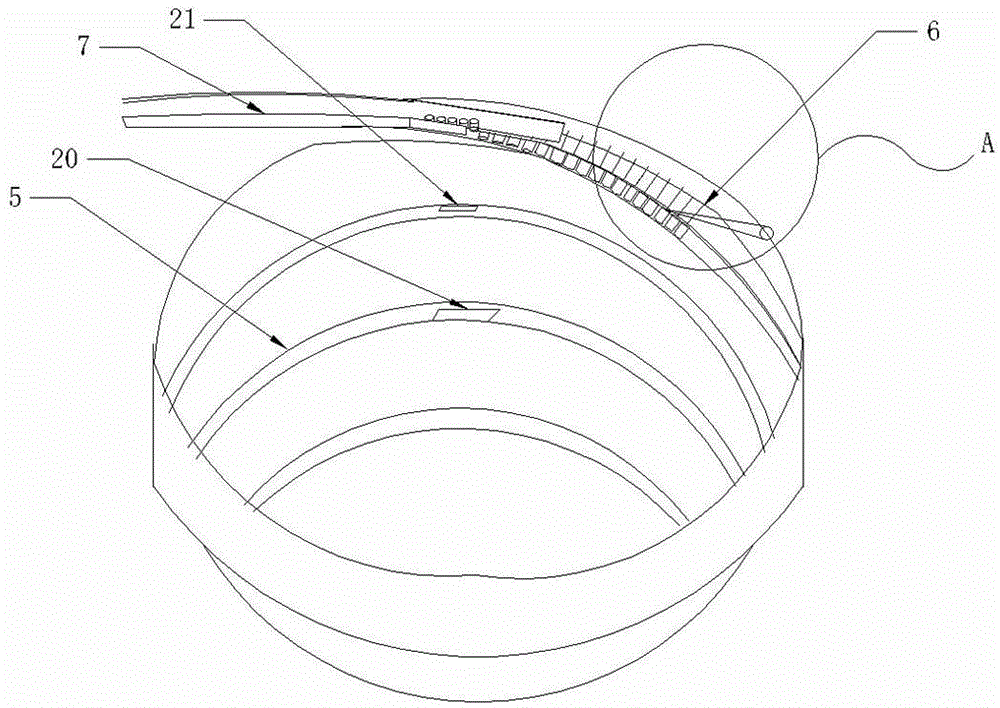

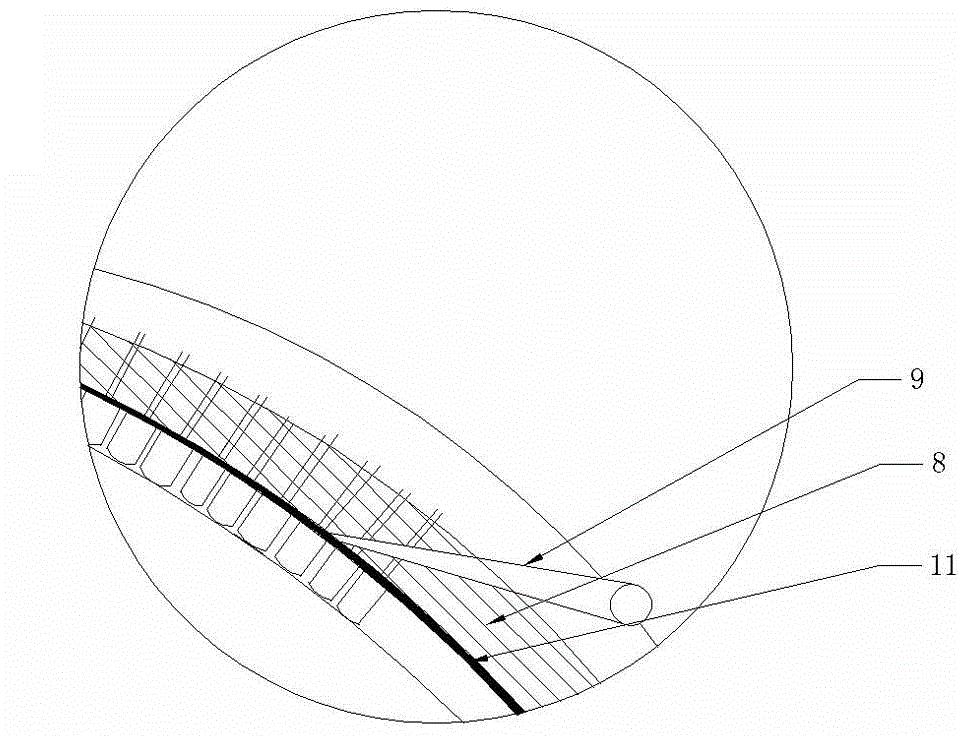

[0024] Such as Figure 1~Figure 4 The shown automatic feeding device for a capacitor includes a frame 1, a vibrating plate 2 is provided on the frame 1, and a material box 3 for feeding is provided above the vibrating plate 2, and the material box 3 is controlled by a controller. The vibrating frame is installed on the frame 1, and the vibrating plate 2 is equipped with a detection device 4 connected with the controller to detect whether there is material in the vibrating plate 2. The inner wall of the vibrating plate 2 is provided with a spiral upward feeding track 5, and the material feeding The end of the track 5 is provided with a capacitor array assembly 6 , and the end of the capacitor array assembly 6 is connected to the conveying trough 7 . The capacitor alignment assembly 6 includes a magnetically conductive shaping plate 8, an electromagnet, an alignment needle 9 and a steering assembly 10; the magnetically conductive shaping plate 8 is arranged along the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com