Implanted spiral electrode and manufacturing method thereof

A spiral electrode and implantable technology, applied in the field of medical devices, can solve problems such as nerve mechanical damage, local tearing, polyester thread shedding, etc., to reduce mechanical damage and physiological damage, reduce viscosity, and enhance connection The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

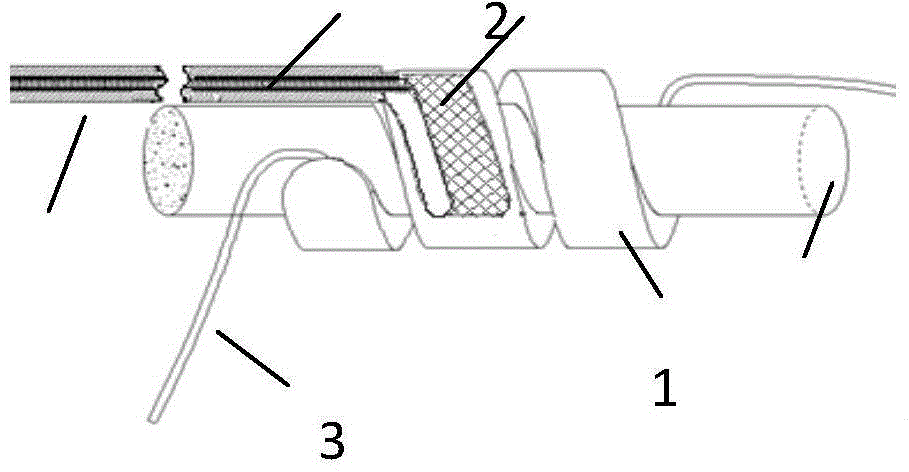

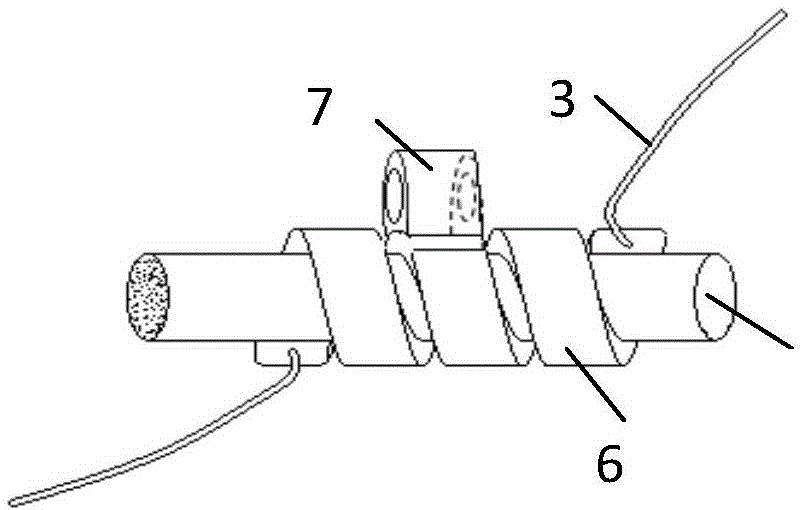

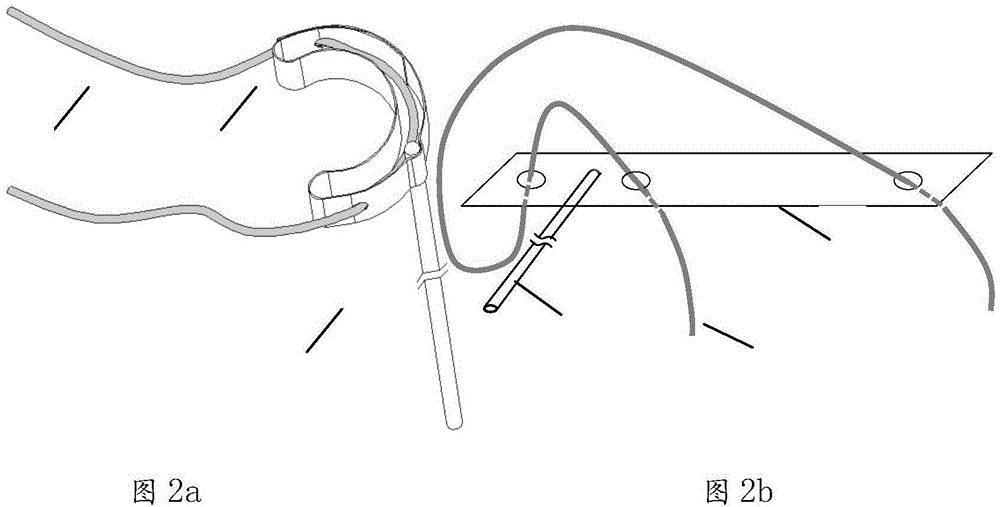

[0034]First, the 4-wire metal spiral conductor 5 is welded on the metal sheet with three round holes by laser welding or resistance spot welding to form the stimulating contact 2; Figure 2b As shown, the pulling wires 3 are respectively passed through the three holes on the metal sheet, and the pulling wires 3 are polyester materials such as biocompatible polyethylene terephthalate. Wrap the stimulation contact 2 of the foil into a Figure 2a The hollow flat ring structure shown ensures that the pulling wire 3 passes through the two ends of the ring-shaped stimulation contact 2, and then the surface layer of the pulling wire 3 exposed outside the flat ring structure is coated with silicon, a biocompatible polymer material. Rubber primer. The metal spiral wire 5 is inserted into the insulating sleeve 4, the insulating sleeve 4 is connected to the first helical body 1 of the stimulating helix, and the connection is filled with a silicone rubber adhesive of a biocompatible poly...

Embodiment 2

[0038] First, the metal spiral conductor 5 of 4 wires is welded on the metal sheet with three round holes by laser welding or resistance spot welding to form the stimulation contact 2; Pass through inside, pull line 3 is the polyester material such as biocompatible polyethylene terephthalate. Wrap the stimulation contact 2 of the foil into a Figure 2a The hollow flat ring structure shown ensures that the pulling wire 3 passes through the two ends of the ring-shaped stimulation contact 2, and then the surface layer of the pulling wire 3 exposed outside the flat ring structure is coated with silicon, a biocompatible polymer material. Rubber primer. Put the traction wire, stimulation contact and metal spiral wire in the mold flatly, and then use the glue filling method to fill the biocompatible solid silicone rubber or polyurethane into the strip-shaped stimulation spiral mold, and take it out after the silicone rubber is vulcanized for a period of time ; Wrap the taken out si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com