Micron panchromatic QLED array device based on deep silicon etching template quantum dot transfer process and preparation method of micron panchromatic QLED array device

A technology of deep silicon etching and quantum dots, which is used in electric solid devices, semiconductor devices, electrical components, etc., can solve the problems of difficulty in filling and transferring multi-color quantum dots, and complicated processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Example 1 Micron full-color QLED array device based on deep silicon etching template quantum dot transfer process

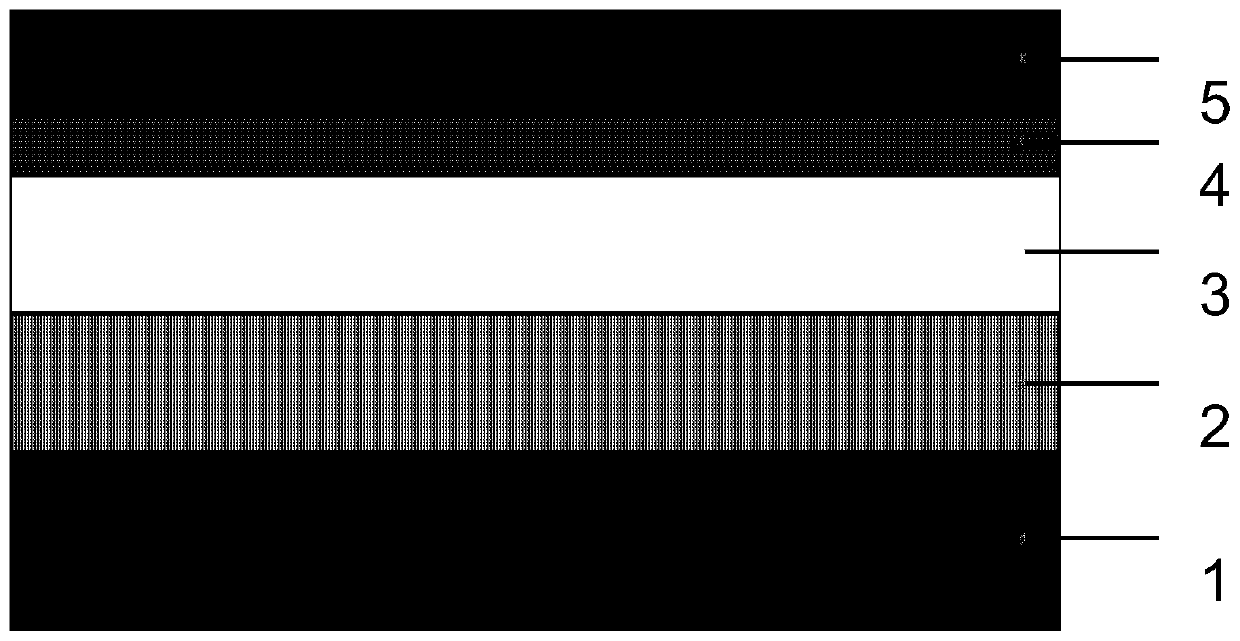

[0085] The epitaxial wafer structure selected for the substrate material in this implementation case is as follows figure 1 As shown, a standard blue LED epitaxial wafer with a p-n structure includes a sapphire substrate 1; a gallium nitride buffer layer 2 grown on the sapphire substrate; an n-type gallium nitride layer 3 grown on the buffer layer; A quantum well active layer 4 on the quantum well active layer; a p-type gallium nitride layer 5 grown on the quantum well active layer.

[0086] The specific preparation method of the Micro-LED array device is as follows:

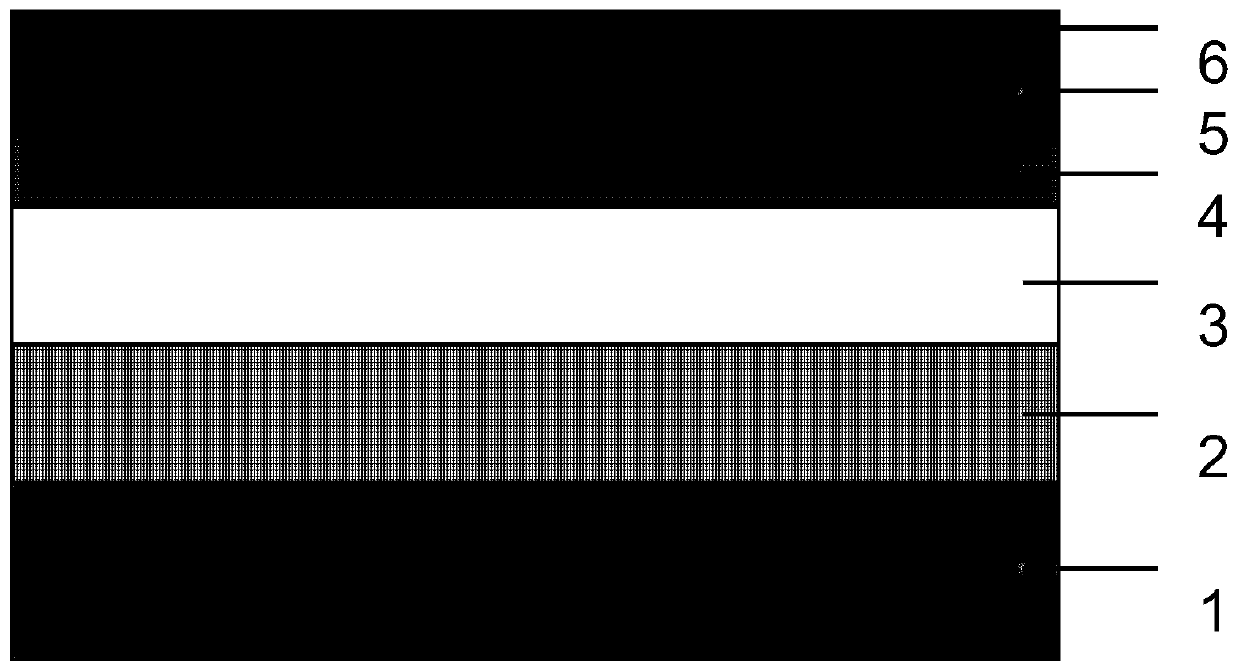

[0087] (1) if figure 2 As shown, using plasma-enhanced chemical vapor deposition (PECVD) technology, in In x Ga 1-x Evaporation of a layer of 150nm thick SiO on N / GaN quantum well blue LED epitaxial wafer 2 Dielectric layer 6, PECVD grown SiO 2 The way is to pass 5% SiH into the react...

Embodiment 2

[0108] Example 2 Micron full-color QLED array device based on deep silicon etching template quantum dot transfer process

[0109] The epitaxial wafer structure selected for the substrate material in this implementation case is as follows figure 1 As shown, a standard blue LED epitaxial wafer with a p-n structure includes a sapphire substrate 1; a gallium nitride buffer layer 2 grown on the sapphire substrate; an n-type gallium nitride layer 3 grown on the buffer layer; A quantum well active layer 4 on the quantum well active layer; a p-type gallium nitride layer 5 grown on the quantum well active layer.

[0110] The specific preparation method of the Micro-LED array device is as follows:

[0111] (1) if figure 2 As shown, using plasma-enhanced chemical vapor deposition (PECVD) technology, in In x Ga 1-x Evaporation of a layer of 200nm thick SiO on N / GaN quantum well blue LED epitaxial wafer 2 Dielectric layer 6, PECVD grown SiO 2 The way is to pass 5% SiH into the react...

Embodiment 3

[0132] Example 3 Micron full-color QLED array device based on deep silicon etching template quantum dot transfer process

[0133] The epitaxial wafer structure selected for the substrate material in this implementation case is as follows figure 1 As shown, a standard blue LED epitaxial wafer with a p-n structure includes a sapphire substrate 1; a gallium nitride buffer layer 2 grown on the sapphire substrate; an n-type gallium nitride layer 3 grown on the buffer layer; A quantum well active layer 4 on the quantum well active layer; a p-type gallium nitride layer 5 grown on the quantum well active layer.

[0134] The specific preparation method of the Micro-LED array device is as follows:

[0135] (1) if figure 2 As shown, using plasma-enhanced chemical vapor deposition (PECVD) technology, in In x Ga 1-x Evaporation of a layer of 250nm thick SiO on N / GaN quantum well blue LED epitaxial wafer 2 Dielectric layer 6, PECVD grown SiO 2 The way is to pass 5% SiH into the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com