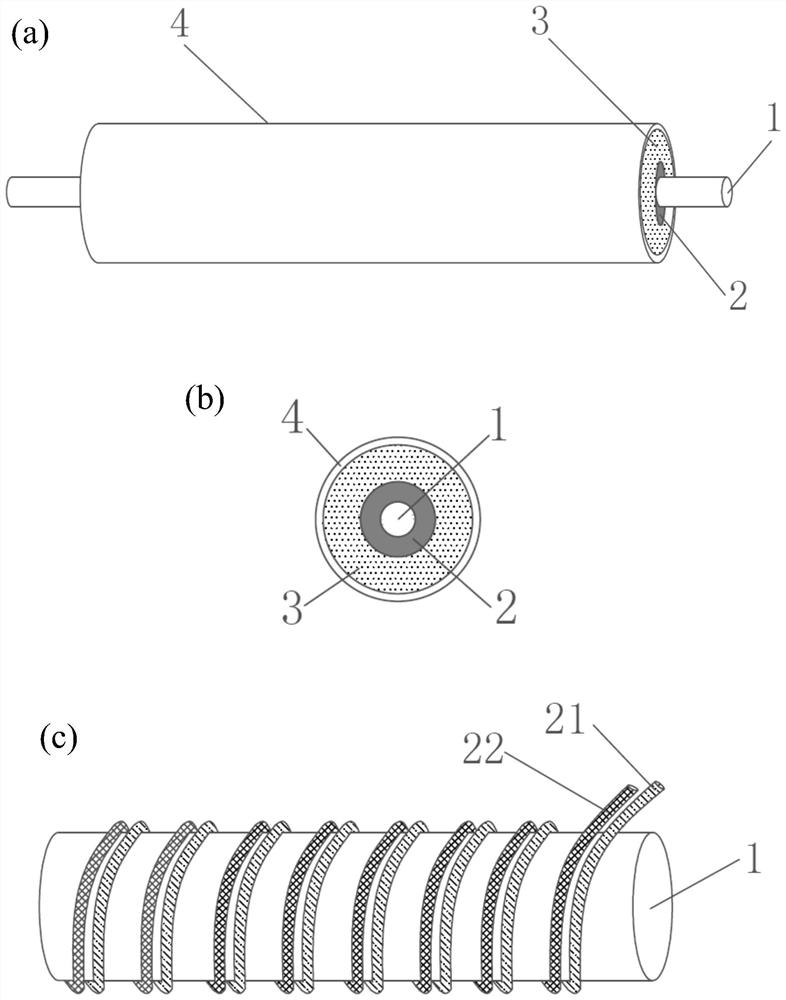

A fiber electrochromic device with wound structure and its application

An electrochromic device and electrochromic technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems that hinder the application and industrialization process of electrochromic fibers, and the difficulty of packaging color-changing fibers, so as to achieve diversified display , The effect of reducing the cost of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

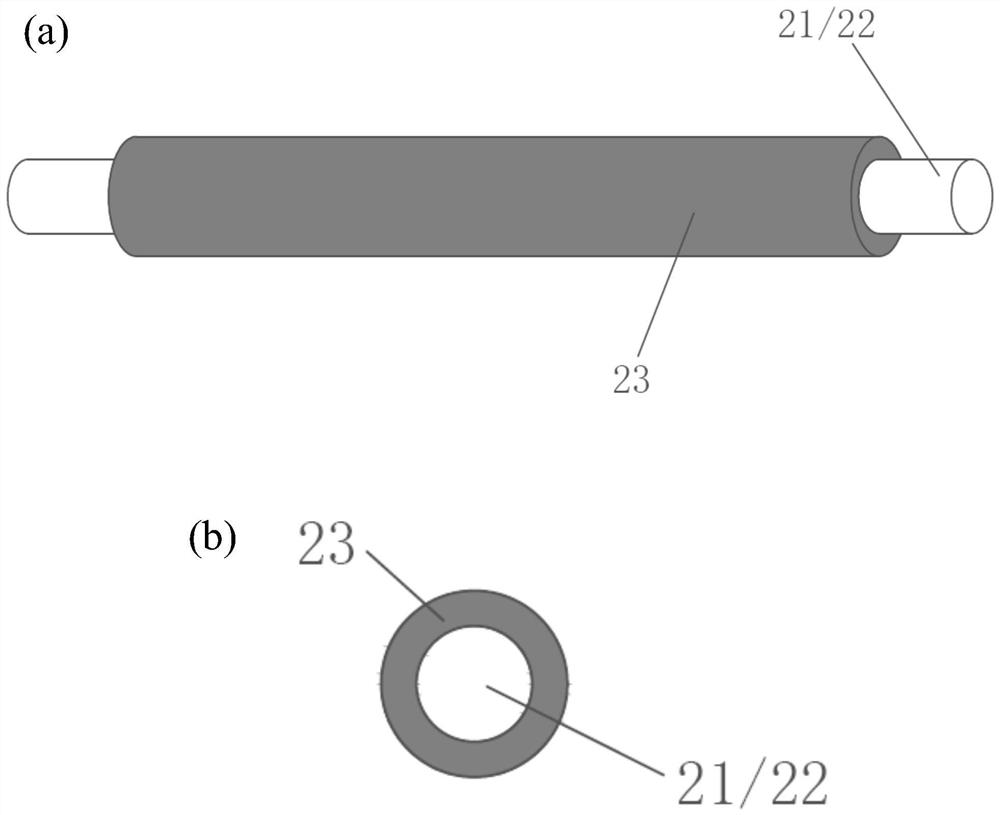

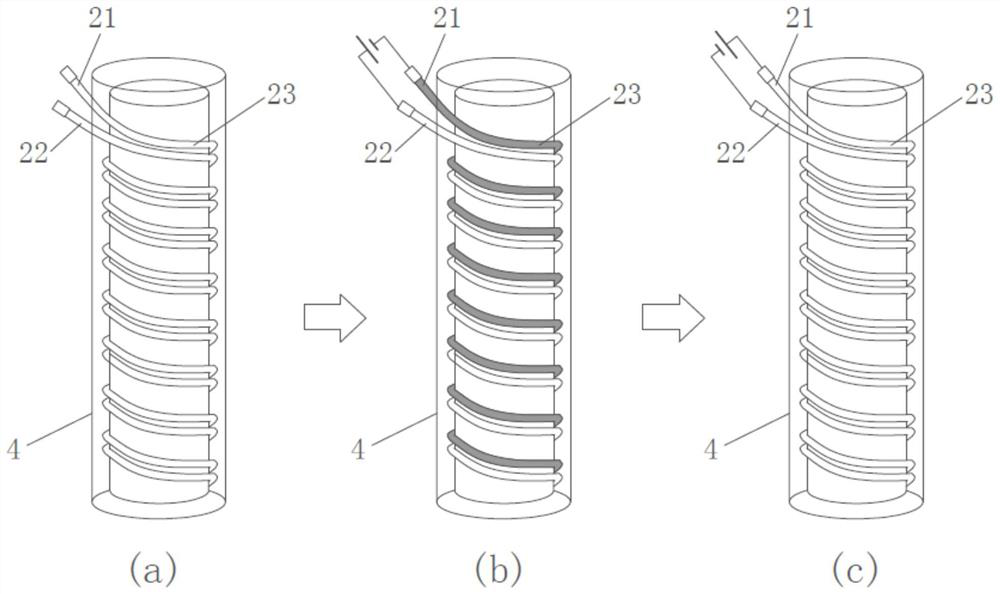

[0061] see Figure 5 , the fiber electrochromic device of the winding structure of the present embodiment has two conductive fibers 21' and 22', wherein, the conductive fiber 21' is a tin wire with a diameter of 6mm, and its surface is covered with a layer prepared by magnetron sputtering. WO 3 The thin film is used as an electrochromic thin film; the conductive fiber 22' is a copper wire with a diameter of 6 mm exposed on the surface.

[0062] Such as Figure 5 (a) and Figure 5 As shown in (b), apply a voltage from the conductive fiber 22' to the conductive fiber 21', the voltage is 0.5V-3V, and the loading time is 1s-300s, then it can be observed that the surface of the conductive fiber 21' is colored, However, the surface color of the conductive fiber 22' remains unchanged.

Embodiment 2

[0064] see Image 6, in this embodiment, the fiber electrochromic device of the winding structure of this embodiment has two conductive fibers 21 "and 22 ", wherein, said conductive fiber 21 " is the tin wire of diameter 6mm, and its surface is covered with through WO prepared by magnetron sputtering 3 film, as an electrochromic film; similarly, the conductive fiber 22 "is a tin wire with a diameter of 6 mm, and its surface is covered with WO prepared by magnetron sputtering. 3 film, as an electrochromic film.

[0065] Such as Image 6 (a)- Image 6 (d) shown. Apply a voltage from the conductive fiber 21" to the conductive fiber 22", the voltage ranges from 0.5V to 3V, and the loading time is 1s to 300s, then it can be observed that the surface of the conductive fiber 22' is colored, but the surface of the conductive fiber 21" is not colored. coloring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com