Oil composition for aluminum processing

An oil composition, aluminum processing technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problem of narrow selection range, achieve good balance, suppress health damage, and suppress odor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

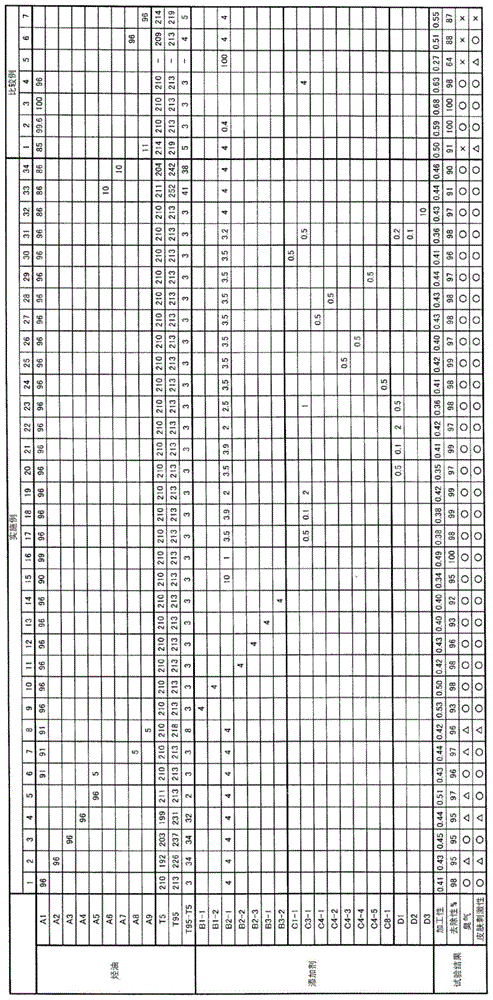

Embodiment 1~34 and comparative example 1~7

[0145] Each lubricating oil composition of the present invention and each lubricating oil composition for comparison shown in Table 1 were prepared, and the following evaluation tests were performed. The results are shown in Table 1 together. The contents (mass %) of hydrocarbon oil and additives are based on the total amount of the composition. In addition, T5, T95, and T95-T5 in the table represent the 5% distillation temperature (°C), the 95% distillation temperature (°C), and the difference between the 5% distillation temperature and the 95% distillation temperature (°C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com