Washing machine recycling water processing device and washing machine

A water treatment device and washing machine technology, which is applied to washing devices, other washing machines, applications, etc., can solve the problems of inability to recycle laundry water and use it, and achieve the effects of preventing flocs from being scattered, simple in structure, and pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

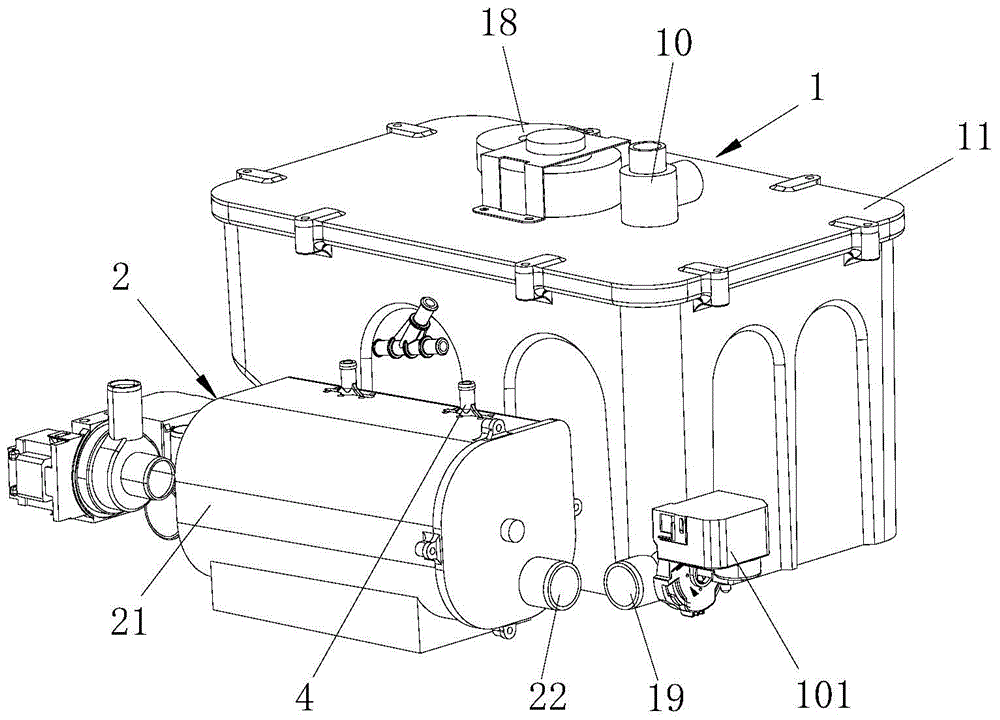

[0044] Such as Figure 4 As shown, the cleaning mechanism described in this embodiment includes a water-spinning impeller 12 that throws the incoming water toward the inner wall of the flocculation container 11 and a driving motor 13 that drives the rotation of the water-spinning impeller 12; The external stirring motor 14 , the stirring shaft 15 extending to the inside of the flocculation container 11 and the stirring impeller 16 installed on the stirring shaft 15 .

[0045] The driving motor 13 described in this embodiment is arranged above the flocculation container, the stirring motor 14 is arranged at the bottom of the flocculation container 11 , and the stirring shaft 15 extends upward to the inside of the flocculation container 11 . In addition to this structure, the stirring motor 14 can also be arranged on the side of the flocculation container 11, and the stirring shaft 15 extends from the side to the inside of the flocculation container 11, or both the stirring moto...

Embodiment 2

[0047] Such as Figure 5 and Figure 6 As shown, this embodiment is a further improvement made on the basis of Embodiment 1. The drive motor 13 and the stirring motor 14 are the same motor, and the water-squirting impeller 12 is coaxially installed on the stirring shaft 15, the bending direction of the stirring impeller 16 is opposite to the direction of rotation of the stirring shaft 15 during the stirring process. The structure of the stirring impeller can not only stir the water flow to accelerate the dissolving of the flocculant, but also prevent the water flow from being too large to break up the flocs. A water guiding groove 17 is arranged in the flocculation container 11 to guide the water from the water inlet 10 of the flocculation container to the impeller 12 for throwing water. The gutter 17 structure is not essential, such as Figure 4 As shown, the water inlet 10 is above the water-spinning impeller 12, and the water enters until on the water-spinning impeller 12...

Embodiment 3

[0051] Such as Figure 6 As shown, the water throwing impeller 12 described in this embodiment includes a turntable 121, an annular rib 122 arranged on the upper surface of the turntable 121 concentric with the center of the turntable, and a plurality of sets of blades 123 whose circumference is distributed outside the annular rib. The direction corresponds to the outer area 124 of the annular rib on the upper surface of the turntable. Multiple groups of blades 123 divide the outer area 124 of the annular retaining rib into multiple small areas, and disperse the water flow when throwing water, so that the water flow is evenly thrown to the surrounding walls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com