Method for main arch closure of three-span hinged arch bridges by adoption of pre-descended and pre-deflected side-span steel trusses

A technology of supported arch bridges and steel truss girders, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as complex stress on the structural system, large tonnage of overall beam shifting, weak overall stability, etc., and achieve saving and adjustment The time spent by Suo Suo, ensuring the stress-free closure of the bridge, and the effect of ensuring stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

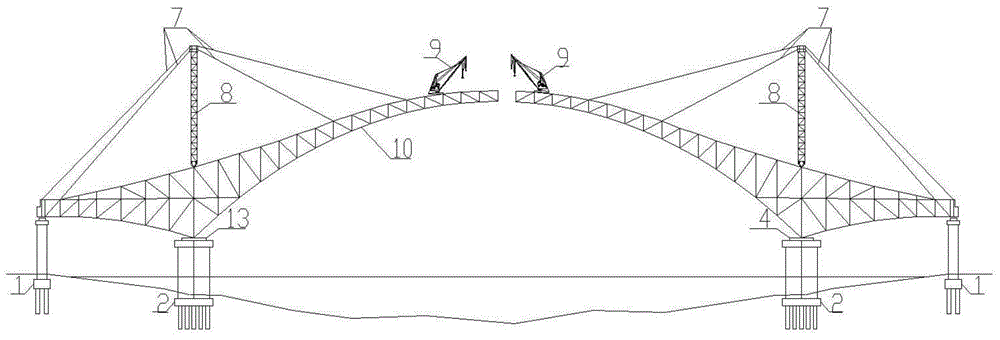

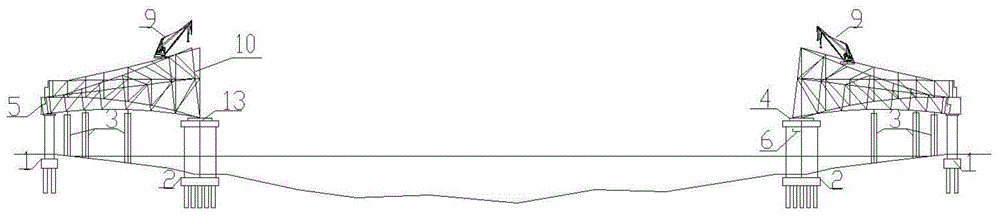

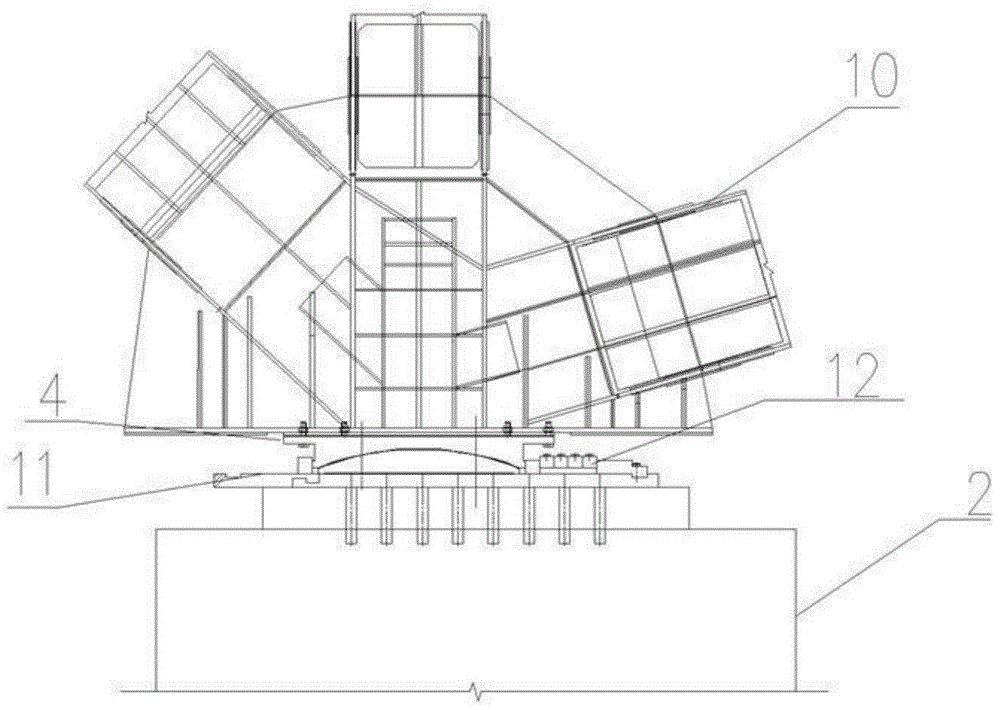

[0026] Such as Figure 1-3 As shown, the present invention provides a method for closing the main arch of a three-span hinge-supported arch bridge with pre-declination and pre-deviating side-span steel truss girders, comprising the following steps:

[0027] Step 1: Pouring the side piers 1 with side spans on both sides, reserve a post-casting section at the top of the side piers 1, and set a fixed hinge support 13 on the main pier 2 of one side span, and the other side span The main pier 2 is provided with a movable hinge support 4, and a temporary pier 3 is arranged between the side pier 1 and the main pier 2 of the two side spans respectively;

[0028] Step 2: erect side-span steel truss girders 10 on the side pier 1 and the temporary pier 3, so that the side-span steel tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com