Curing technology of frozen shaft concrete inner layer shaft wall with liquid foam

A technology for concrete and frozen wells, which is applied in wellbore lining, shaft equipment, earthwork drilling and mining, etc. It can solve the problems of continuous supply of warm water, large consumption of spraying water, and difficulty in water temperature control, so as to reduce maintenance water and improve the quality of wellbore , good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] First, prepare a high-fold protein foam stock solution according to the following formula:

[0040] Water, its weight is 54% of high multiple protein foam stock solution weight;

[0041] Animal protein foaming agent, its weight is 44% of the weight of high multiple protein foam stock solution;

[0042] Sodium dodecylbenzene sulfonate, its weight is 1.5% of the weight of high multiple protein foam stock solution;

[0043] Gelatin, its weight is 0.5% of the weight of high multiple protein foam stock solution.

[0044] Wherein, the animal protein foaming agent is a foaming agent produced by hydrolyzing hooves, horns or / and hair of cattle or sheep.

[0045] Then the prepared high-expansion protein foam stock solution is stored in a foam stock solution storage tank for subsequent use.

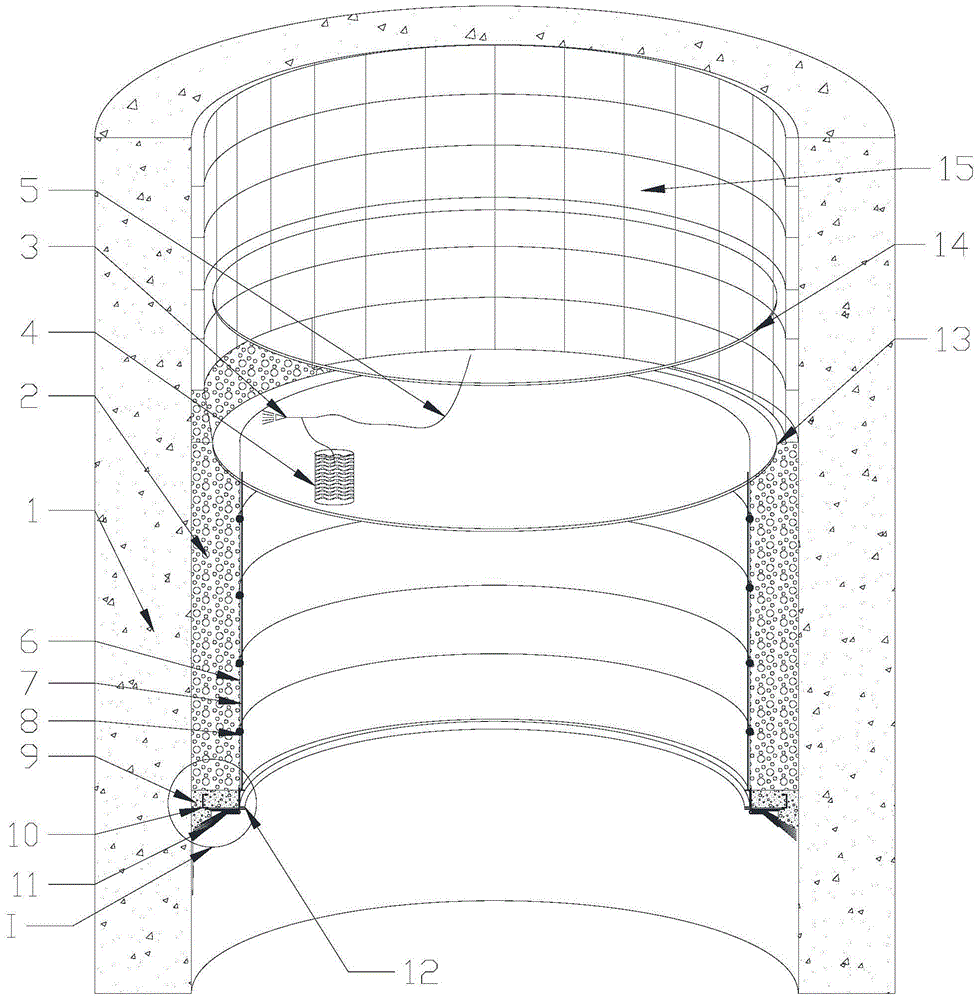

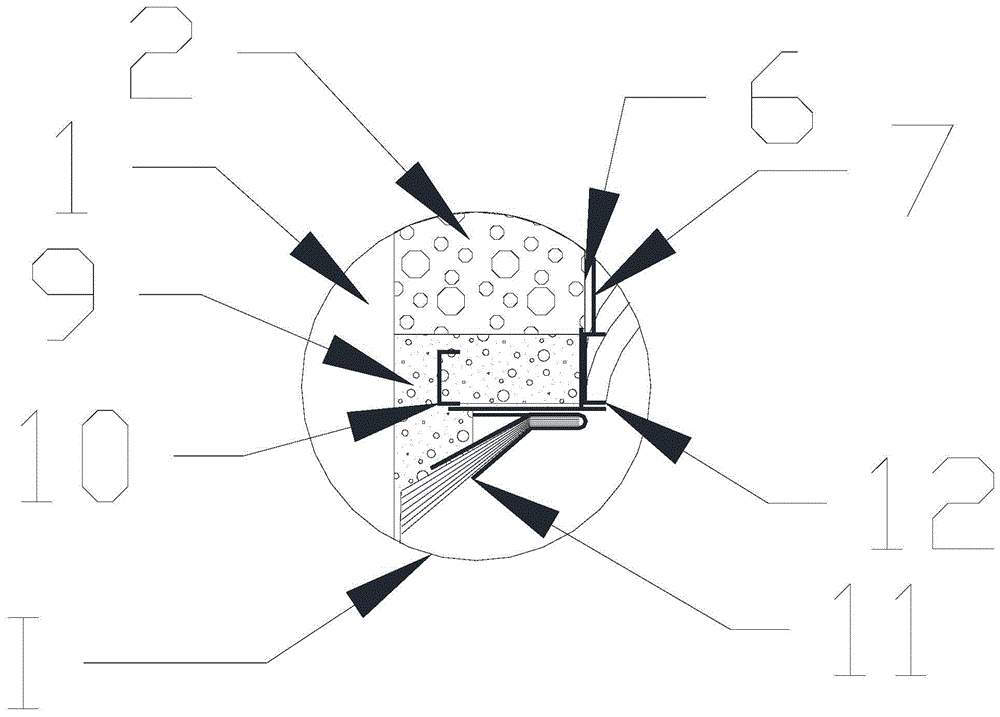

[0046]In order to save cost and foam stock solution, and at the same time, in order not to affect the construction of other well sections in the frozen shaft, in this embodiment, a foam cu...

Embodiment 2

[0052] Prepare high-fold protein foam stock solution according to the following formula:

[0053] Water, its weight is 50% of the weight of the stock solution of high multiple protein foam;

[0054] Animal protein foaming agent, its weight is 45% of the weight of high multiple protein foam stock solution;

[0055] Sodium dodecylbenzene sulfonate, its weight is 3.5% of the weight of high multiple protein foam stock solution;

[0056] Gelatin, its weight is 1.5% of the weight of high multiple protein foam stock solution.

[0057] Wherein, the animal protein foaming agent is a foaming agent produced by hydrolyzing hooves, horns or / and hair of cattle or sheep.

[0058] In this example, except that the component content of the high-expansion protein foam stock solution is different from the component content of the high-expansion protein foam stock solution in Example 1, other steps and conditions are the same.

[0059] The use of the high-fold protein foam stock solution in thi...

Embodiment 3

[0061] Prepare high-fold protein foam stock solution according to the following formula:

[0062] Water, its weight is 53% of high multiple protein foam stock solution weight;

[0063] Animal protein foaming agent, its weight is 45% of the weight of high multiple protein foam stock solution;

[0064] Sodium dodecylbenzene sulfonate, its weight is 1.0% of the weight of high multiple protein foam stock solution;

[0065] Gelatin, its weight is 1.0% of the stock solution weight of high multiple protein foam.

[0066] Wherein, the animal protein foaming agent is a foaming agent produced by hydrolyzing hooves, horns or / and hair of cattle or sheep.

[0067] In this example, except that the component content of the high-expansion protein foam stock solution is different from the component content of the high-expansion protein foam stock solution in Example 1, other steps and conditions are the same.

[0068] The use of the high-fold protein foam stock solution in this embodiment c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com