Heater arrangement

A heater and commutator technology, applied in water heaters, fluid heaters, heating methods, etc., can solve problems such as pressure rise, damage, noise, etc., and achieve the effect of reducing assembly accuracy and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

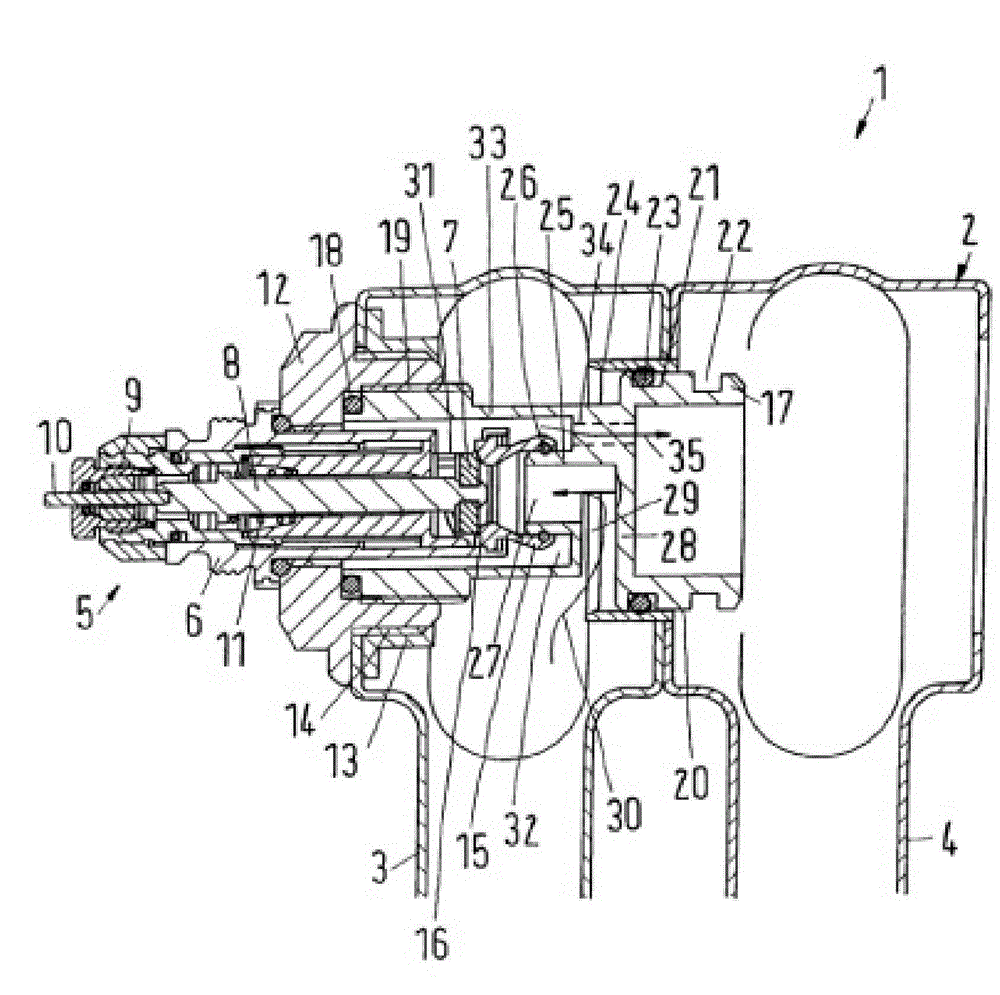

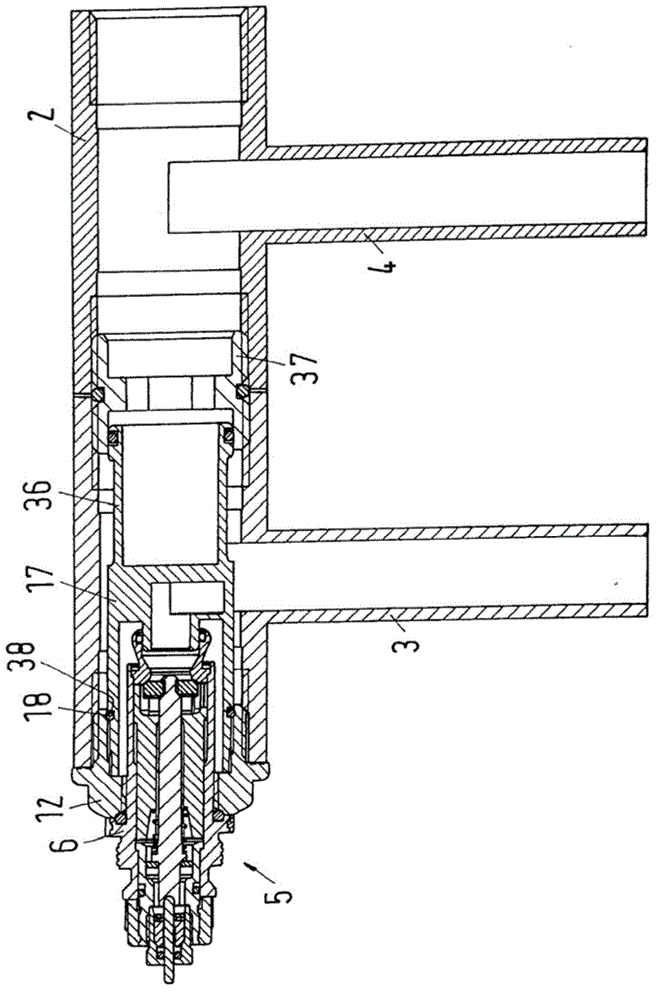

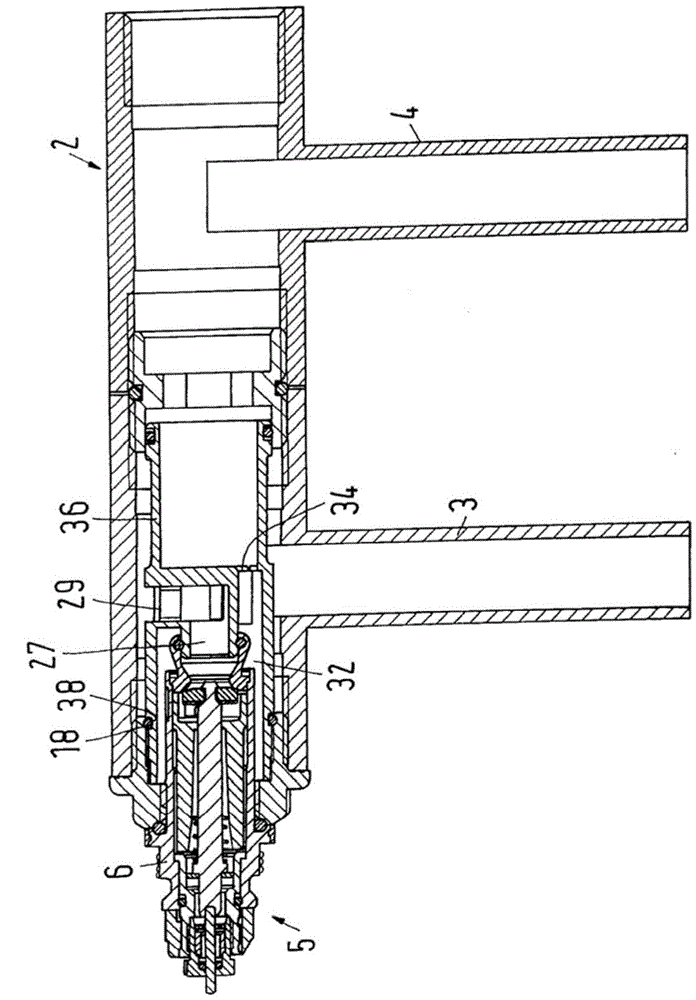

[0025] figure 1 A sectional view of a heater arrangement 1 is shown, which comprises a heater 2 designed as a segmented heater with a first section 3 and a second section 4 . Further segments of the heater are connected to the second segment 4 in a manner not shown in greater detail.

[0026] In a heater 2 of this type, the first section 3 is repeatedly used as a water inlet section for a heat transfer fluid, especially hot water, to flow through the heater. The remaining section 4 is used as a return section. However, all segments 3, 4 are used as heat exchange surfaces.

[0027] A valve 5 is provided for controlling the flow of heat transfer fluid through the heater 2 . The valve 5 has a valve body 6 in which a valve element 7 is movably arranged. The valve member 7 is moved via a shaft 8 which in turn acts via an actuating pin 10 which passes through the gland 9 . An end cover, not shown in detail, usually a thermostatic valve cover, acts on the actuating pin 10 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com