Dual wedge clamp angled blade cutter system

A technology of blade and cutting head, applied in the field of blade assembly, which can solve the problems of high risk and tedious labor intensity of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] This application claims a U.S. provisional application filed January 31, 2013 by inventors Todd Domer, Paul Jones, Jonathan McMichael and Daniel Chase Priority of Serial No. 61 / 759,043, the contents of which are hereby incorporated by reference.

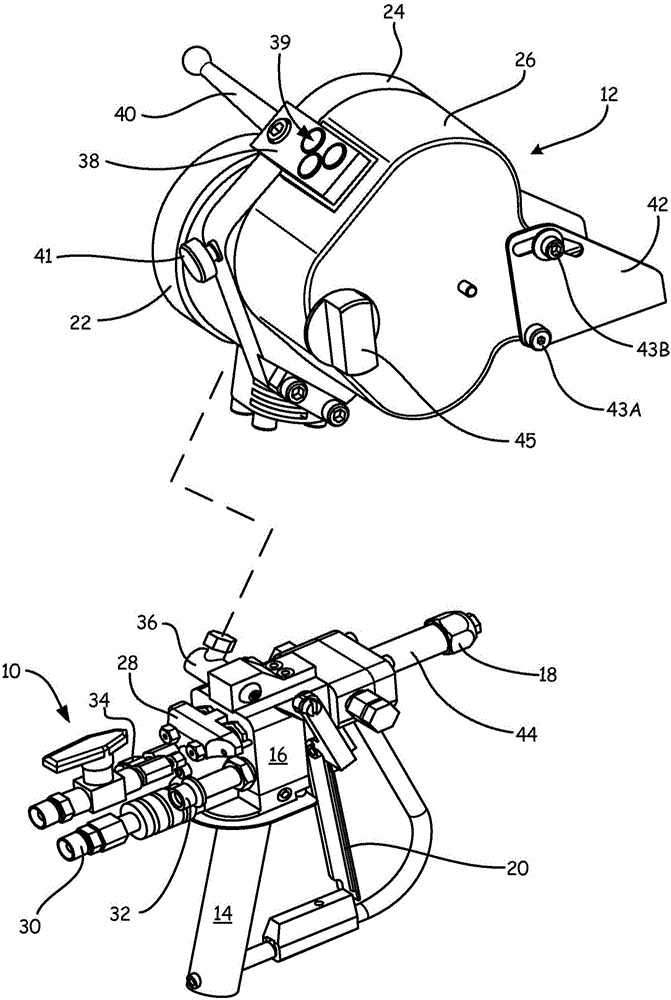

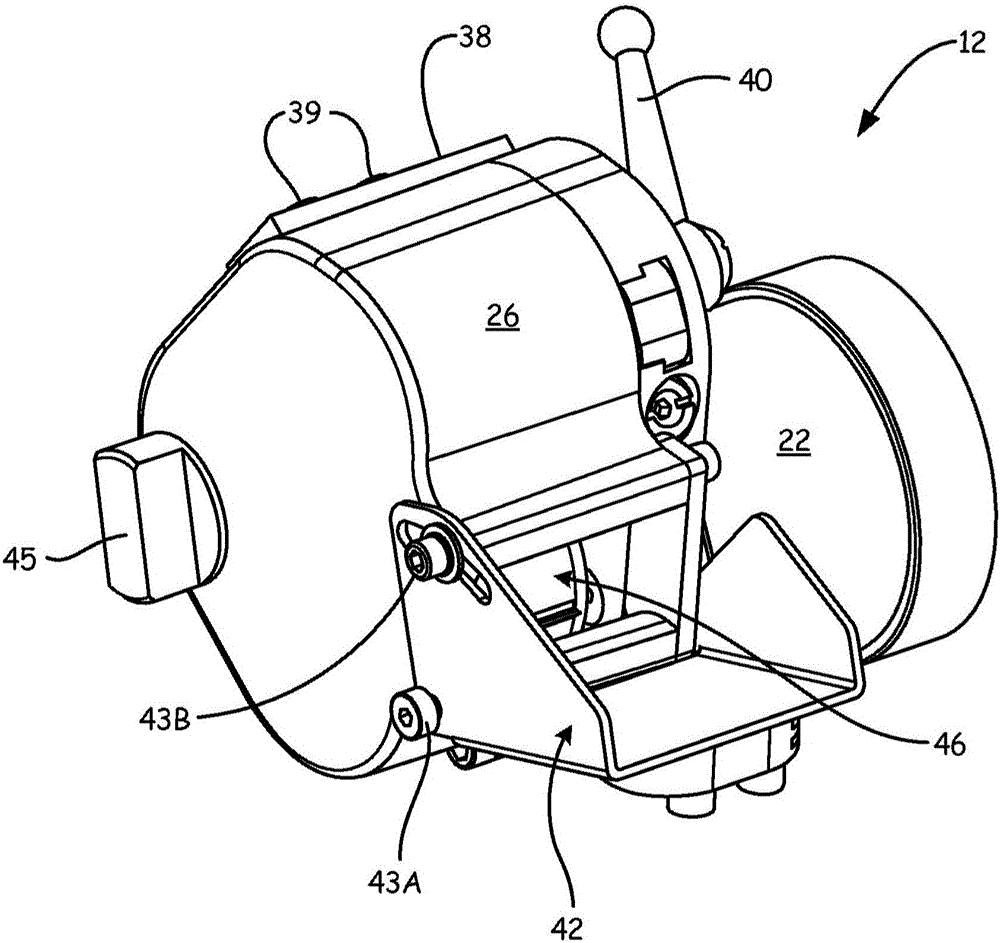

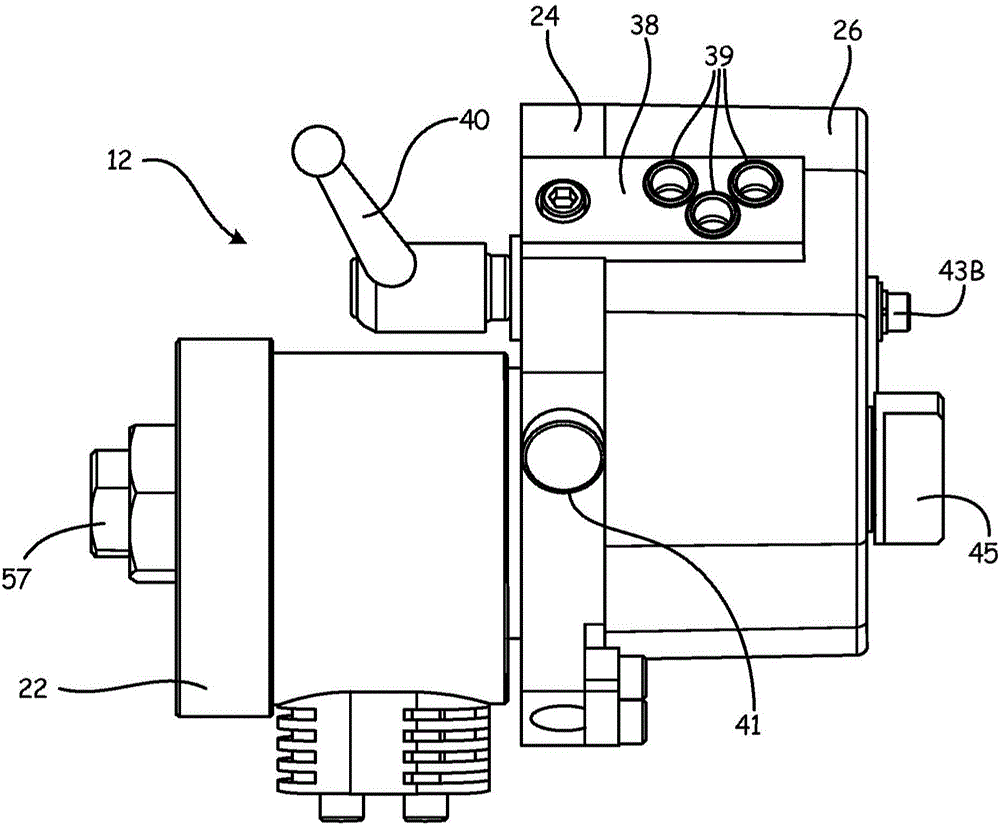

[0021] figure 1 is an exploded view of the assembly of a liquid spray gun 10 and a fiber roving chopper 12 utilizing the cutting head assembly of the present invention. exist figure 1 , the fiber roving chopper 12 is shown slightly enlarged relative to the liquid spray gun 10 . The liquid spray gun 10 includes a two-component internal mixing gun having a handle 14 , a valve body 16 , a nozzle 18 and a trigger 20 . The fiber roving chopper 12 includes an air motor 22 , a housing 24 and a cover 26 . Valve body 16 of spray gun 10 includes valve assembly 28 , air inlet 30 , material inlet 32 , catalyst inlet 34 and air outlet 36 . Housing 24 of fiber roving chopper 12 includes fiber inlet 38 , opening 39 , lever 40 , knob 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com