Soybean milk filter equipment

A filtration equipment and soymilk technology, applied in filtration and separation, fixed filter element filter, application, etc., can solve the problem of inconvenient fixing of filter cloth, and achieve the effect of firm connection and increase of fixed area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

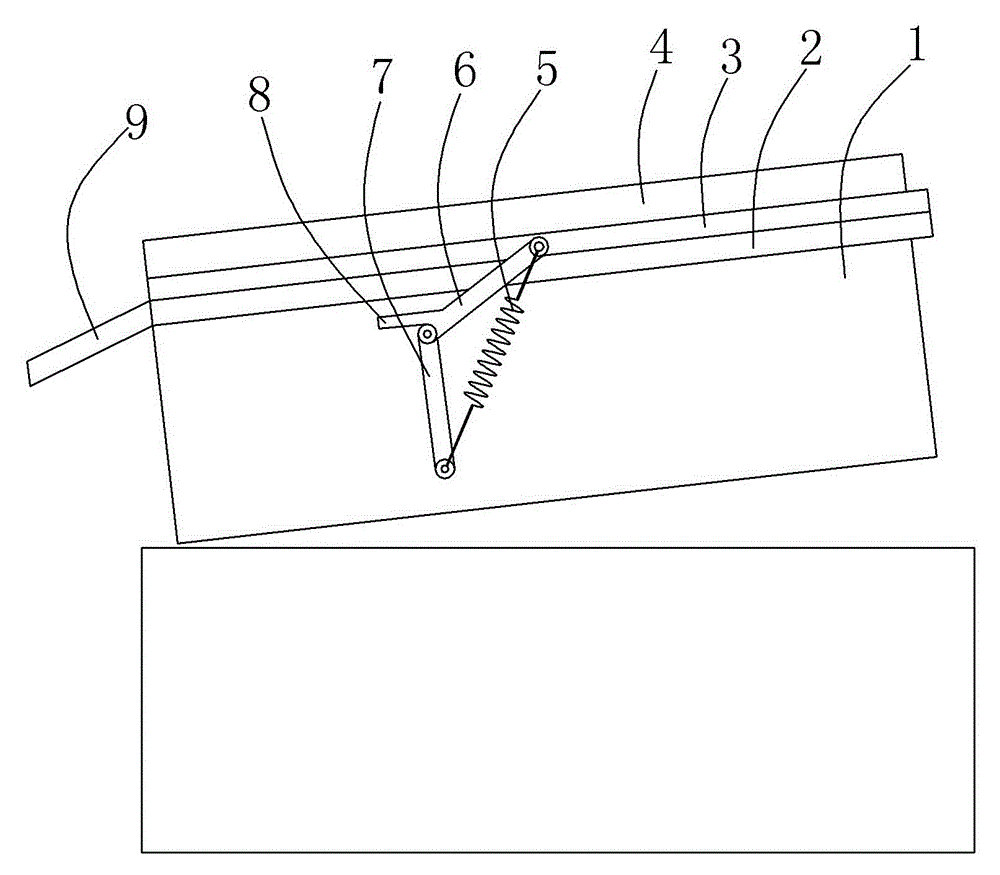

[0012] Among the figure: filter box 1, splint 2, pressure plate 3, baffle plate 4, spring 5, rotating arm 6, fixed block 7, limit block 8, slag discharge plate 9.

[0013] Such as figure 1 The soybean milk filtering equipment shown comprises a filter box 1 shaped as a cuboid, the front and back sides of the filter box 1 are longer, and the left and right sides are shorter. The front, rear and right sides of the top of the filter box 1 are provided with splints 2 protruding from the outside of the filter box 1, and the left side of the top of the filter box 1 is provided with an inclined slag plate 9 protruding outward. Pressing plate 3 is positioned at the top of filter case 1 and with clamping plate 2, the width of pressing plate 3 is identical with the width of clamping plate. A baffle 4 is provided on the top surface of the pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com