Composite machining die for switch shaft aluminum post

A technology of compound processing and switching shafts, which is applied in the direction of manufacturing tools, metal processing equipment, casting molding equipment, etc., can solve the problems of increasing the production cost investment of manufacturers, and achieve the effects of increasing the scope of use, reducing development costs, and facilitating control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

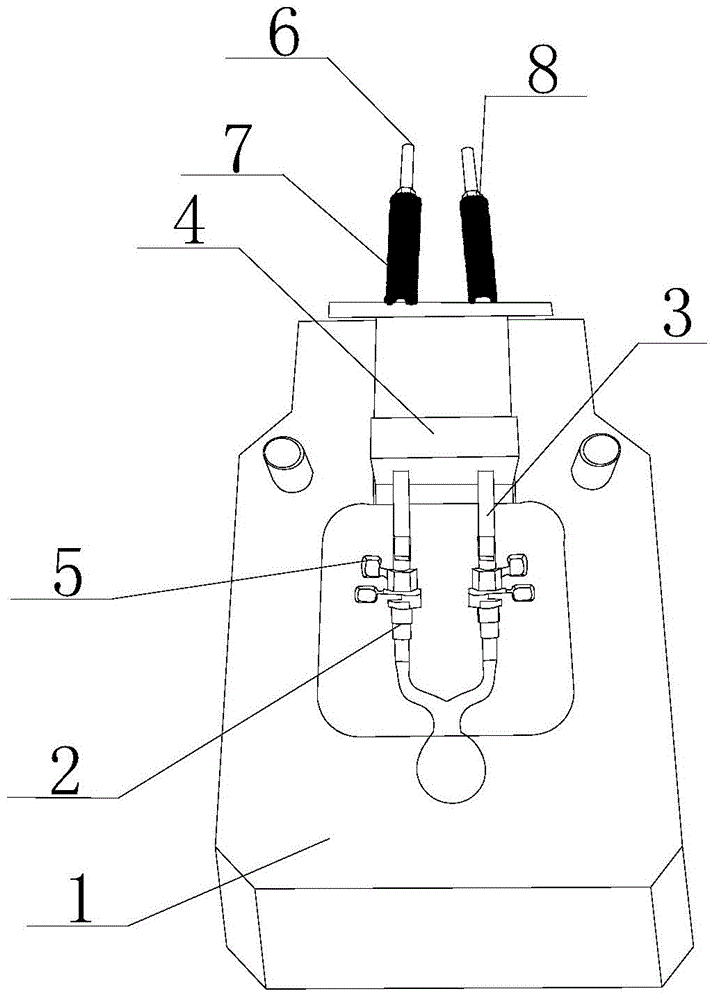

[0012] This embodiment provides a compound processing mold for the aluminum column of the switch shaft, the structure is as follows figure 1 As shown, it includes an upper mold and a lower mold 1, and a casting groove 2 consistent with the outer dimension of the switch shaft is provided in the lower mold and the upper mold, and two casting grooves arranged between the lower mold and the upper mold are arranged side by side, and the lower mold The top of the casting groove is provided with a boss to form the inner cavity of the switch shaft. The boss is a replaceable metal post 3, and the top of the metal post is fixed by a connecting seat 4. The connecting seat is connected by a fine-tuning control rod arranged on the outside of the lower mold. The casting groove side of mold and patrix is provided with air-guiding groove 5, and air-guiding groove communicates with casting groove.

[0013] The fine-tuning control rod in this embodiment includes an adjusting screw 6, a return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com