A device for on-line installation of automotive windshield metal studs

A windshield and metal nail technology, which is applied in metal processing, metal processing equipment, vehicle parts, etc., can solve the problem of reducing the bonding strength of metal nails and windshields, detrimental to the safety performance of automobile windshields, and preheating metal nails. Time inconsistency and other problems, to achieve accurate and fast grasping and bonding, compact structure, good process continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

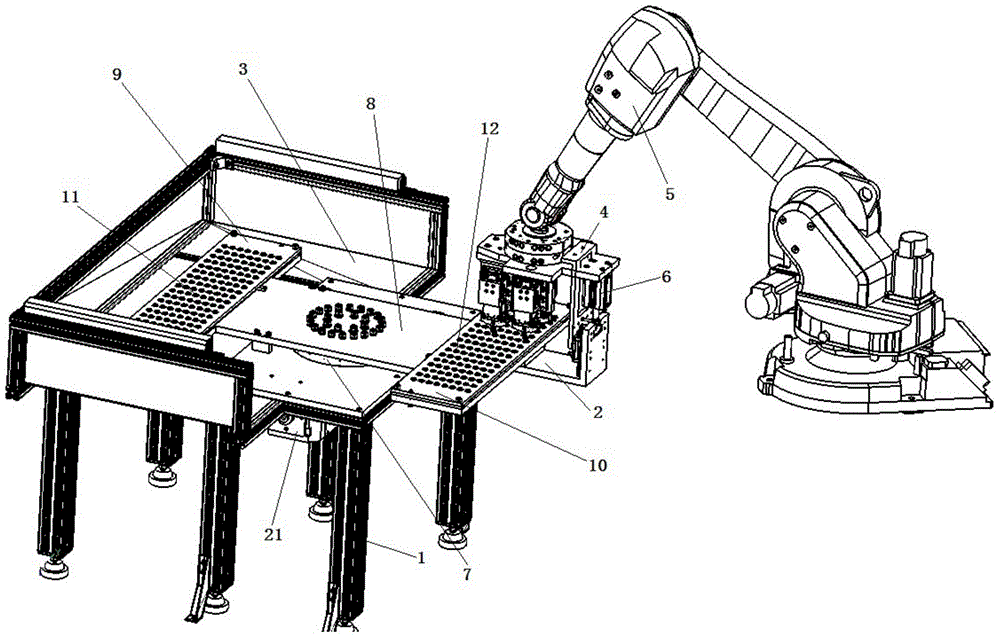

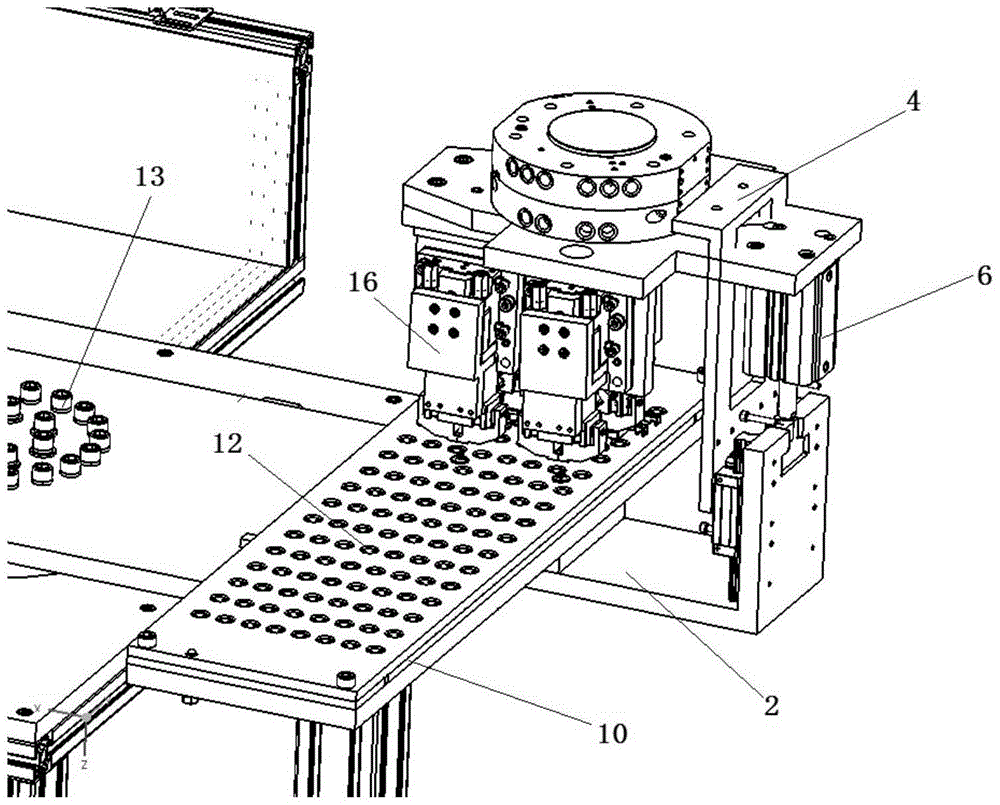

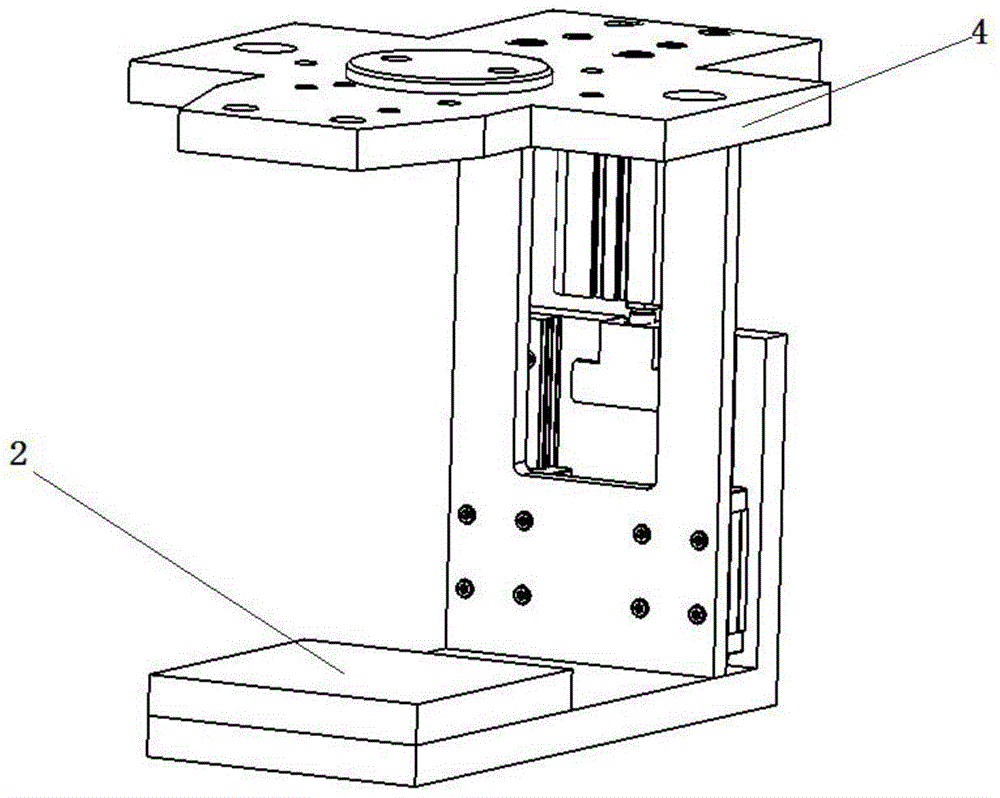

[0038] like Figure 1-3 As shown, a device for on-line installation of metal nails for automobile windshields includes a support frame 1, a rotation mechanism arranged on the support frame 1, a pick-up mechanism used in cooperation with the rotation mechanism, and a pick-up mechanism opposite to the pick-up mechanism. The crimping plate 2, the support frame 1 is provided with a worktable 3, the pick-up mechanism is installed on the five-axis manipulator 5 through the connecting plate 4, and a crimping cylinder 6 is also provided on one side of the connecting plate 4, and the crimping cylinder 6 is connected with the crimping The plate 2 is connected by transmission. The crimping plate 2 is set on the connecting plate 4 so as to be movable up and down through the crimping cylinder 6. The rotating mechanism includes a motor 21 arranged on the support frame 1, a rotary table 7 connected to the motor 21 by transmission, The rotating arm 8 fixedly connected with the rotating table ...

Embodiment 2

[0046] In this embodiment, the tip of the set screw 14 is 0.3 mm higher than the bottom surface of the cylindrical positioning groove, and the rest is the same as that of Embodiment 1.

Embodiment 3

[0048] In this embodiment, the tip of the set screw 14 is 0.6 mm higher than the bottom surface of the cylindrical positioning groove, and the rest is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com