D-pillar structure for automobile and method of making the same

A column structure and automobile technology, which is applied in the superstructure, superstructure sub-assemblies, vehicle parts, etc., can solve the problems of difficult realization of welding joints of the body frame, difficulty in stamping and forming of parts, and low modal stiffness of the body. Body performance, work efficiency improvements, effects of increased stiffness and modalities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

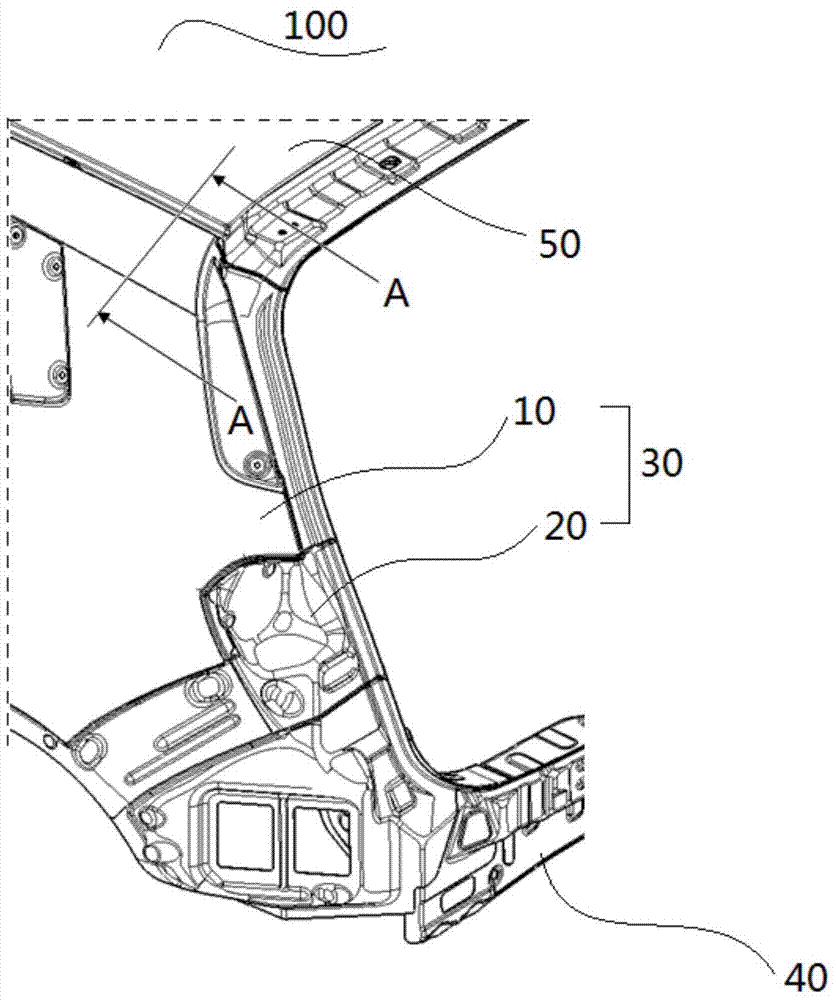

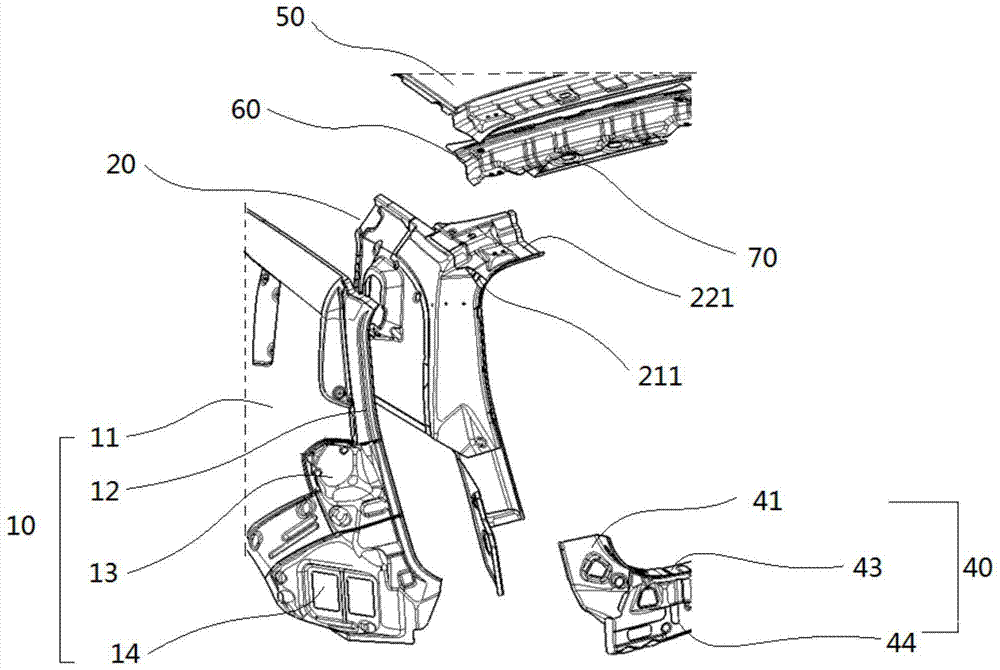

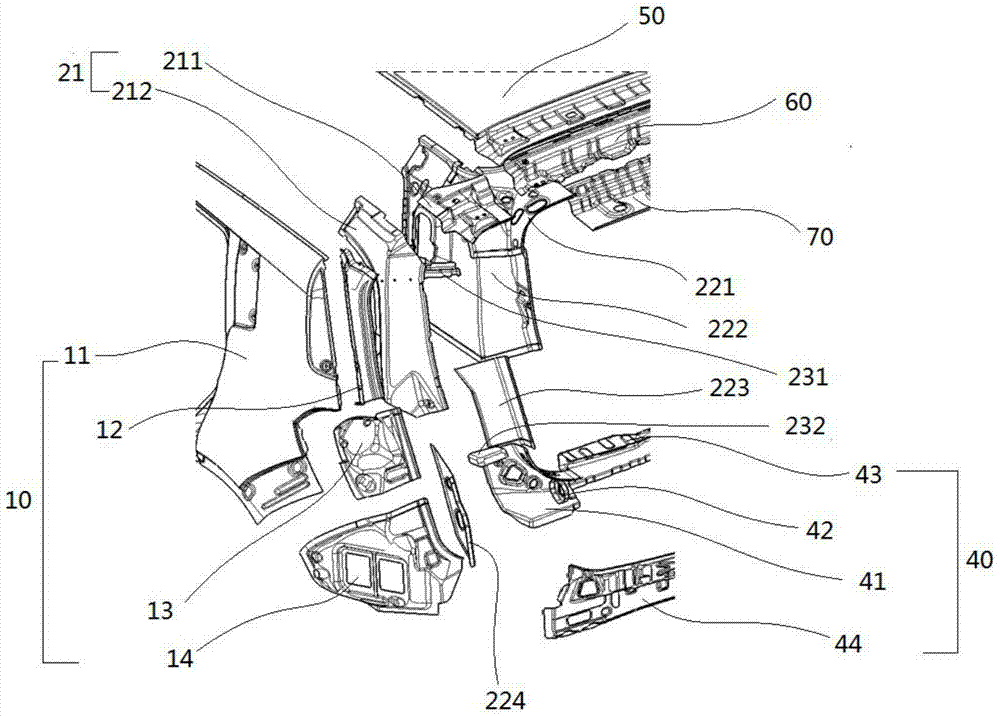

[0048] see figure 1 , which shows a D-pillar structure 100 for an automobile according to an embodiment of the present invention. combine figure 2 As shown, the D-pillar structure 100 includes a side panel assembly 30 , an underbody assembly 40 , a roof outer panel 50 , a rear roof beam reinforcement panel 60 and a rear roof beam inner panel 70 . The upper end of the side wall assembly 30 , the roof outer panel 50 , the rear roof beam reinforcement plate 60 and the rear roof beam inner panel 70 are fixedly connected to each other, and the lower end of the side wall assembly 30 is fixedly connected to the lower body assembly 40 . Specifically, such as figure 2As shown, the side wall assembly 30 includes a side wall outer panel asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com