Composite jump takeoff system for heavy gyroplane with jump takeoff capability

A rotorcraft, heavy-duty technology, applied in the direction of aircraft, rotorcraft, motor vehicles, etc., can solve the problems of inapplicability, limited rotor inertia, etc., achieve the effect of convenient processing, increase the jumping height, and simplify the structure of the transmission system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

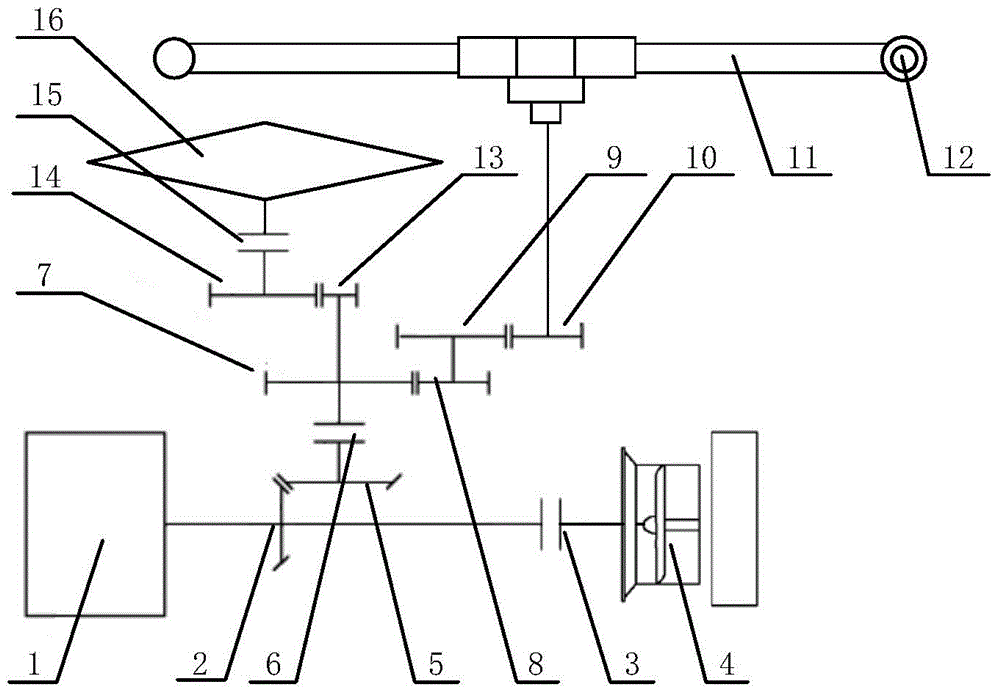

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

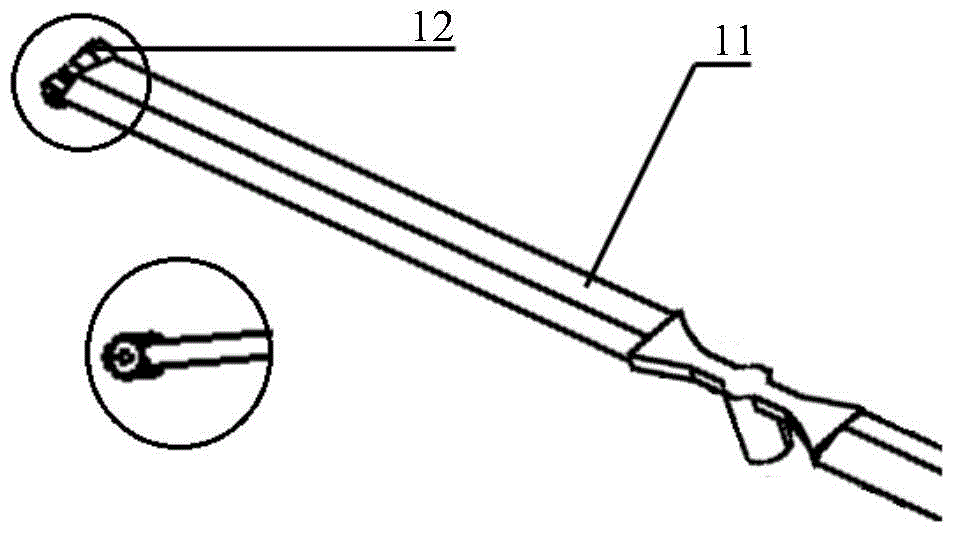

[0013] A compound jumping system for a heavy-duty jumpable autorotor aircraft, the structure of which is as follows: figure 1 , 2 As shown, the end of the output shaft of the engine 1 is connected with the tail vector propulsion duct 4 through the friction clutch 3, the first helical bevel gear 2 is arranged on the output shaft of the engine 1, the second helical bevel gear 5 and the first helical bevel gear The bevel gear 2 meshes, and the second helical bevel gear 5 changes the transmission direction of the engine 1; the output end of the second helical bevel gear 5 is connected with the third helical cylindrical gear 7 through an electromagnetic clutch 6, and here it is divided into two ways of transmission: the first In one transmission, the third helical spur gear 7 meshes with the fourth helical spur gear 8, the fourth helical spur gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com