A tea automatic packaging machine

An automatic packaging machine and tea technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of insufficient automation, low equipment utilization rate, and low production efficiency, so as to achieve smooth tea packaging process and improved packaging efficiency , the effect of diversified functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

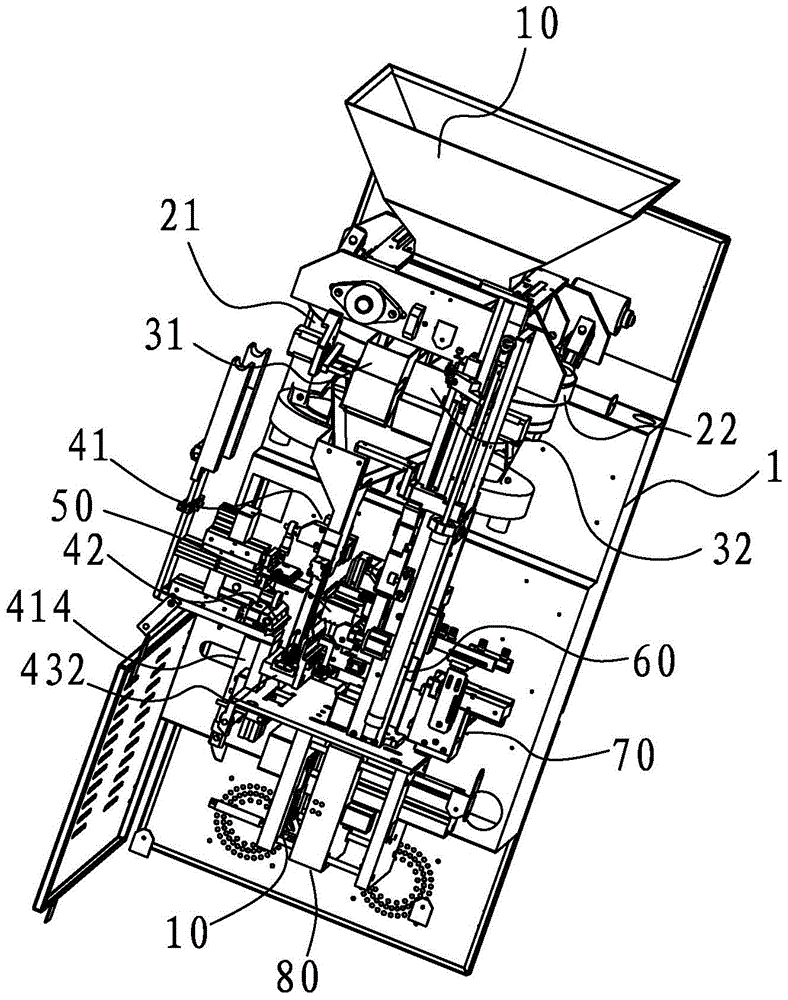

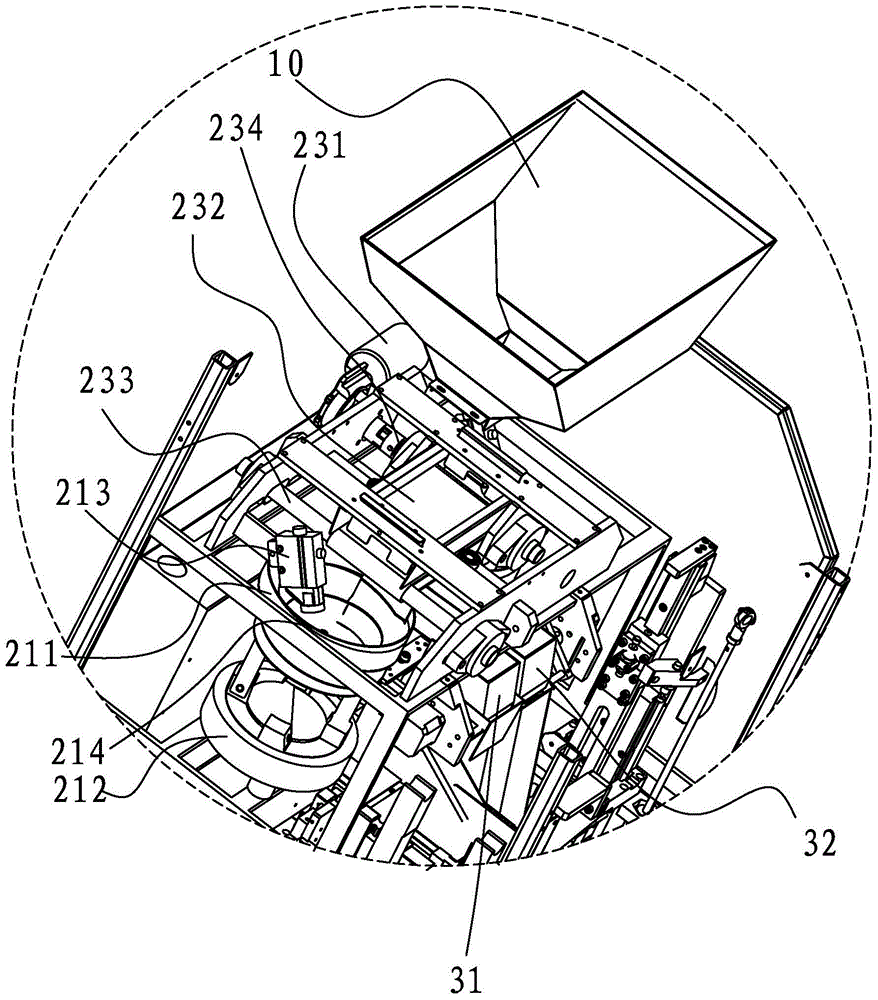

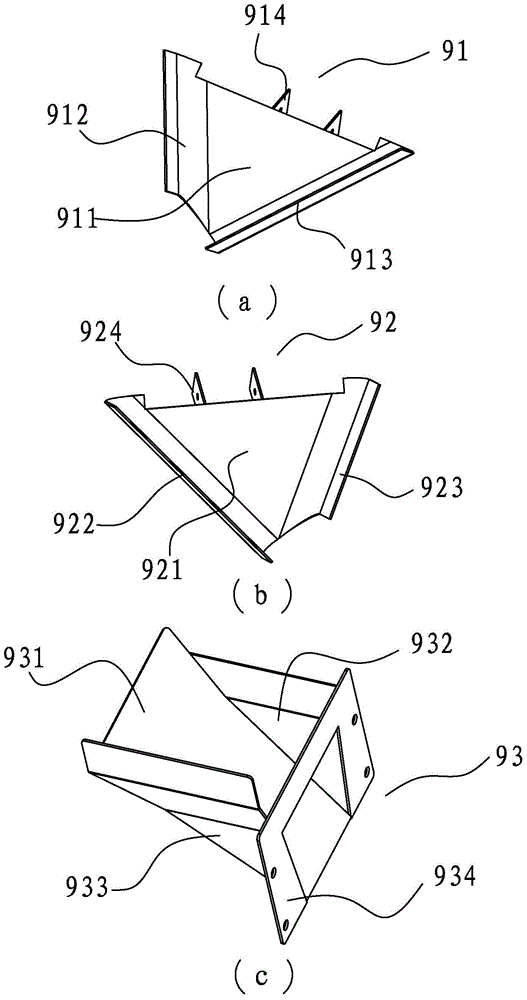

[0091] refer to Figure 1 to Figure 12 , an automatic packaging machine for tea, comprising a frame 1 and a hopper 10 arranged on the frame 1, a feeding mechanism, a metering device, an inner bag charging mechanism 41, an inner bag making mechanism 42, and an inner bag making mechanism 42 are arranged below the hopper 10. Bag film supply mechanism, outer bag filling mechanism 60, outer bag supply mechanism 70, conveying mechanism 50 for sending the inner bag of tea leaves from inner bag charging mechanism 41 to outer bag charging mechanism 60, vacuum sealing device 80 and a PLC control device (not shown in the figure), the timing and actions of each mechanism are controlled by the PLC control device. The inner bag film supply mechanism includes a film winding mechanism 431 and a stretching mechanism 432 for o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com