Parting conveying method and parting conveying device for aerated concrete products

A technology for aerated concrete and conveying devices, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of damage to aerated concrete products, affect the working efficiency of the production line, and occupy a large area, so as to reduce damage Probability, movement reduction, and the effect of reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the drawings and embodiments, but it is not used as a basis for any limitation on the invention.

[0027] A method for splitting and conveying air-entrained concrete products, comprising the steps of:

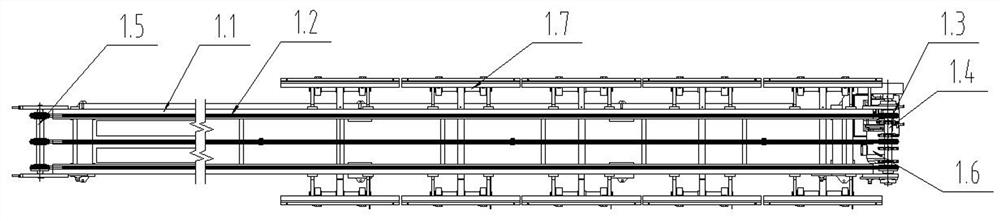

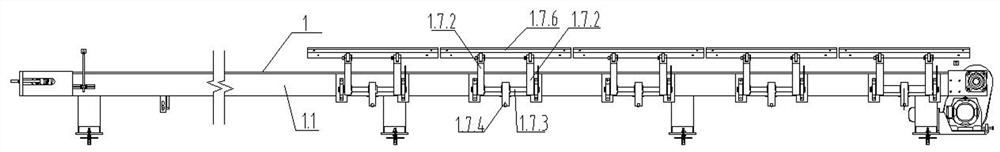

[0028] Step 1, transport the steamed and cured aerated concrete products into stacks to the splitting station on the conveyor line 1 by the conveyor line, and the conveyor line stops conveying;

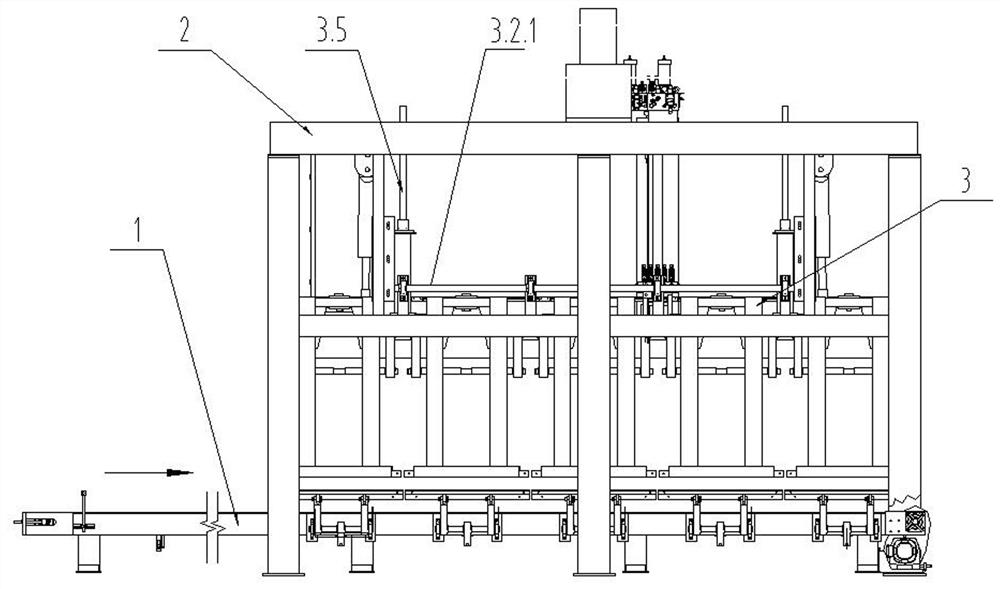

[0029] Step 2: On the splitting station, firstly, the bottom layer of the stack of aerated concrete products is clamped by the clamping device 1.7 on the conveying line 1, and the bottom of the stack of aerated concrete products is clamped by the clamping mechanism 3 above the splitting station. The second bottom layer; secondly, raise the clamping mechanism 3 to clamp the remaining aerated concrete products except the bottom layer in the aerated concrete product stack, so that the bottom aerated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com