stair climbing manual forklift

A technology for manual forklifts and stairs, applied to motor vehicles, crawler vehicles, lifting devices, etc., can solve the problem that the machinery that can go up stairs is blank, and achieve the effects of small vibration, simple structure, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

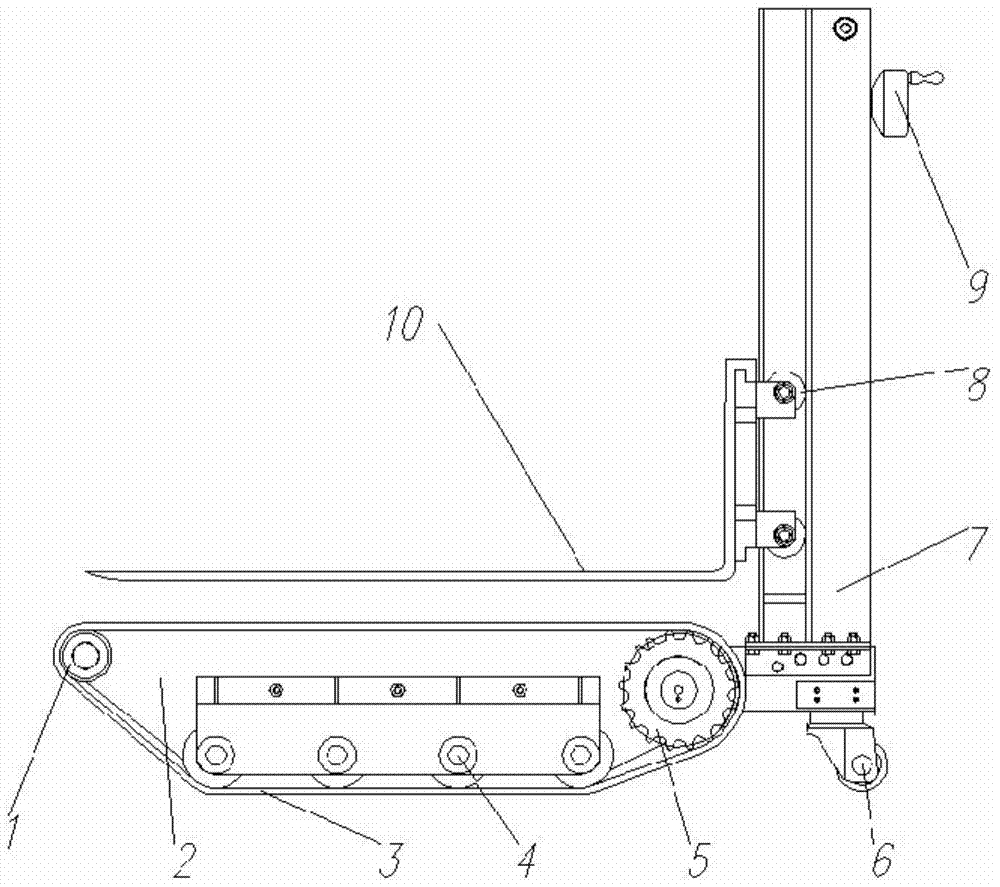

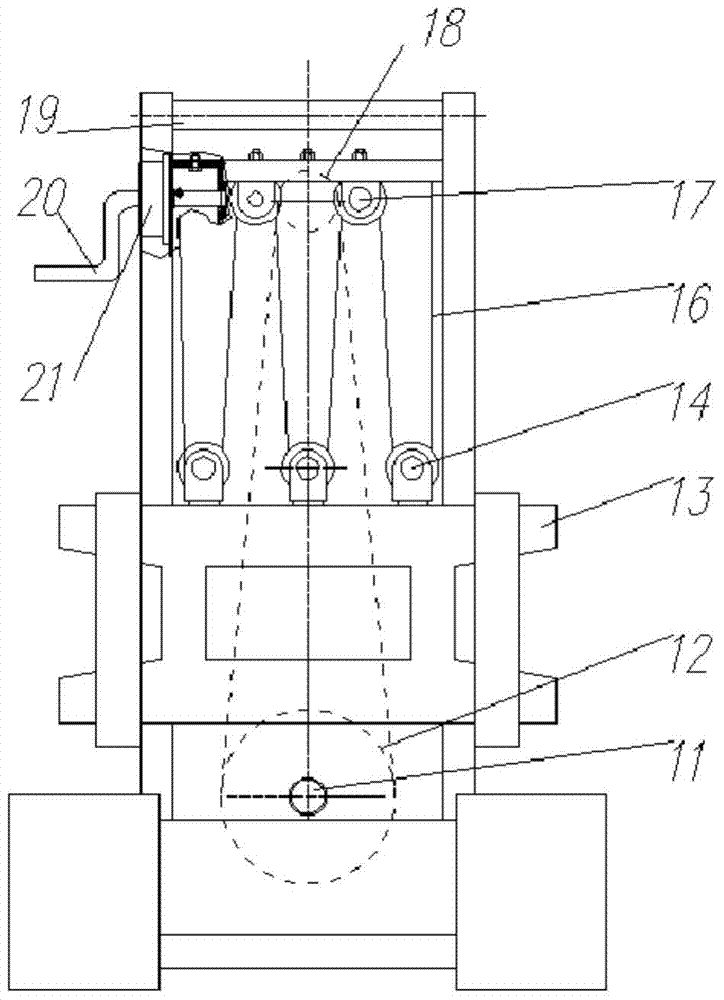

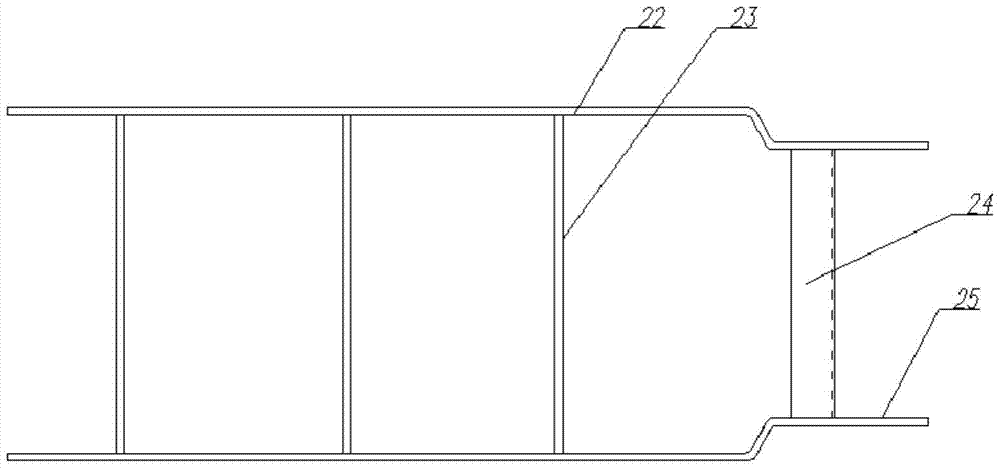

[0028] Such as figure 1 and figure 2 As shown, the stair-climbing manual forklift includes a bracket, a crawler traveling mechanism, a traveling driving mechanism, a cargo loading mechanism, a cargo lifting mechanism and an auxiliary mechanism.

[0029] Wherein, the support includes a chassis frame 2 and a door frame 7, the door frame 7 is fixed on one side of the chassis frame 2, and both are arranged in an L shape, and an armrest 19 is provided on the upper end of the door frame 7.

[0030] The crawler running mechanism is responsible for the traveling and climbing functions of the forklift that can go up the stairs manually. The crawler running mechanism is fixed on the chassis frame and has an inverted trapezoidal structure. Composition, driven wheel 1, driving wheel 5 and bearing wheel 4 are all installed on the chassis frame 2. Wherein, the driving wheel 5 is located at the rear of the chassis frame 2, the driven wheel 1 is located at the front, and the bearing wheels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com