Liquid medicine material accurate filling mechanism

A medicine and precise technology, applied in the field of precise filling mechanism for liquid medicine, can solve the problems of long contact time and low accuracy, achieve low cost, improve filling accuracy, and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

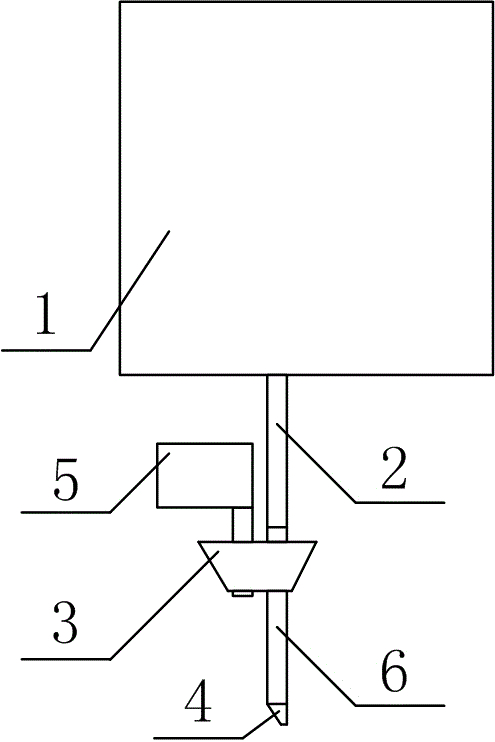

[0024] Accurate filling mechanism for liquid medicine, such as figure 1 As shown, it includes a liquid material tank 1 and a liquid material pipe 2. The liquid material pipe 2 is threadedly connected with a liquid material pipe on-off control mechanism 6, and the bottom end of the liquid material pipe on-off control mechanism 6 is connected with a tapered The sealing member 3, the bottom end of the liquid material pipe on-off control mechanism 6 runs through the conical sealing member 3 and the bottom end is provided with a discharge port 4, and the conical sealing member 3 is also provided with a Air suction device 5.

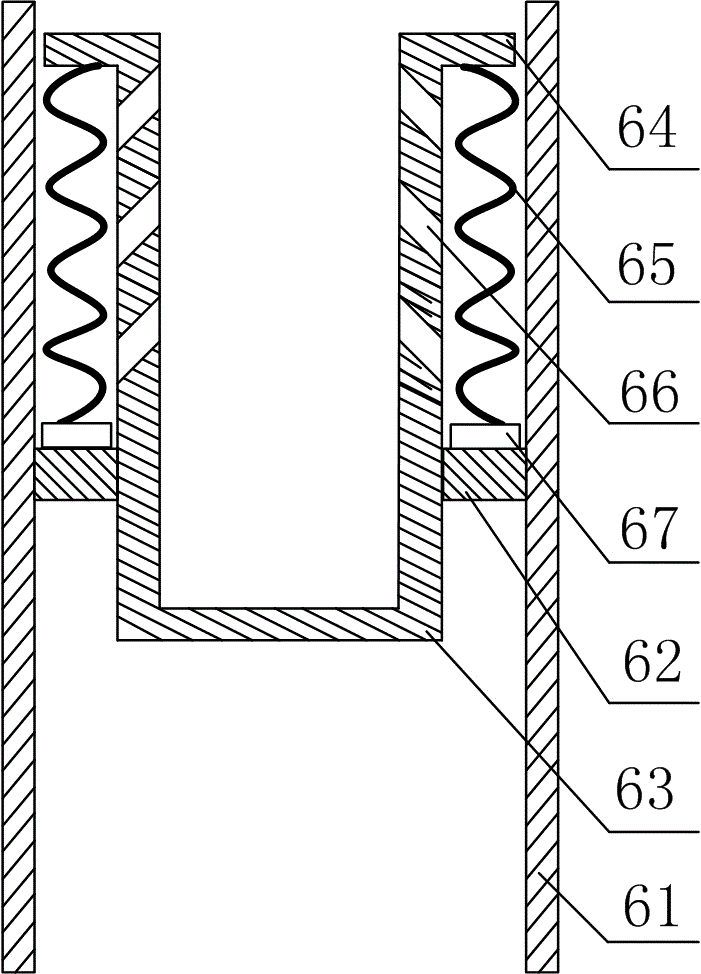

[0025] The liquid material pipe on-off control mechanism 6 includes a connecting pipe 61 that is threaded and sealed with the liquid material pipe 2, and a mounting seat 62 that is fixed on the inner wall of the connecting pipe 61 and has a through hole. The matching "U" groove 63, the first spring connecting seat 64 arranged at the top of the "U" groove 63, ...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that in this embodiment, the specific structure of the on-off control mechanism of the liquid material pipe is optimized, such as figure 2 As shown, the specific settings are as follows:

[0033] The on-off control mechanism of the liquid material pipe also includes a second spring connecting seat 67, and the two ends of the spring 65 are respectively fixedly connected with the first spring connecting seat 64 and the second spring connecting seat 67, and the second spring connecting seat 67 and the mounting seat 62 are connected by bolts. In this embodiment, the liquid material pipe 2 and the liquid material tank 1 are connected by bolts.

[0034] Through the above arrangement, the cleaning work when filling different medicinal liquids can be facilitated, and the pollution of the latter medicinal liquid by the former medicinal liquid can be avoided when filling different medicinal liquids.

Embodiment 3

[0036] The difference between this embodiment and Embodiment 2 is: the structure of the discharge hole 66 is further optimized in this embodiment, as figure 2 As shown, the specific settings are as follows:

[0037] The cross-section of the "U"-shaped groove 63 is a circular tube, and there are more than one discharge holes 66, which are evenly distributed in a ring shape around the "U"-shaped groove 63 . The discharge hole 66 on the longitudinal section of the "U" groove 63 is in the shape of "eight".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com