Blast furnace gas diffusing tower

A technology of blast furnace gas and release towers, which is applied in the direction of discharge devices, etc., can solve the problems of low release efficiency of blast furnace gas release towers, difficulty in cleaning, easy dust accumulation in blast furnace gas release towers, etc., and achieve good release effect, low manufacturing cost and stability Sexual Enhancement Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

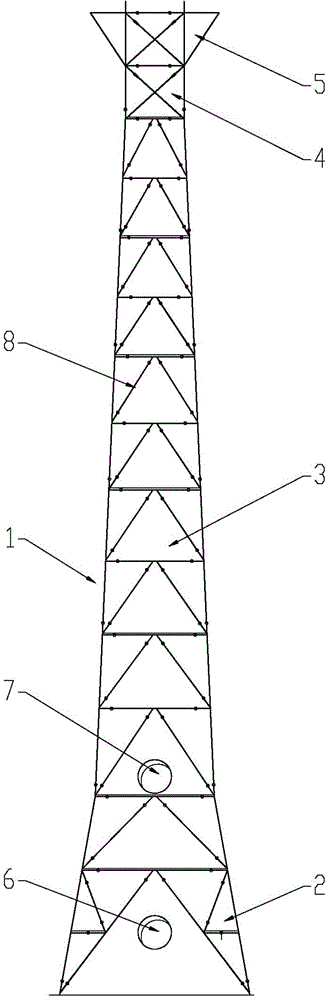

[0016] Such as figure 1 Shown: a blast furnace gas release tower, including a tower body 1, the tower body 1 consists of a base tower section 2, a main tower section 3, a top tower section 4 and a V-shaped tower mouth 5, each section of the tower body 1 The body is welded with inverted V-shaped ribs 8 to strengthen the stability of the tower body 1, wherein the base tower section 2 and the main tower section 3 are both in the shape of a cone and the top tower section 4 is a cuboid, and the cone of the base tower section 2 The angle is 16° to 25° and the cone angle of the main tower section 3 is 4° to 10°. The above settings make the diameter of the tower body 1 from bottom to top show a change of rapid shrinkage, slow shrinkage, non-shrinkage, and expansion, so that the divergence The tower has high emission efficiency and is not easy to accumulate dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com