Process for preparing rare earth silicon alloy with rare earth enrichment

A rare earth silicon alloy and rare earth enrichment technology, applied in the field of making rare earth silicon alloy from rare earth enrichment, can solve the problems of affecting the yield of rare earth, insufficient agglomerate strength, narrow selection range, etc., so as to reduce environmental pollution and improve agglomeration. Block strength, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

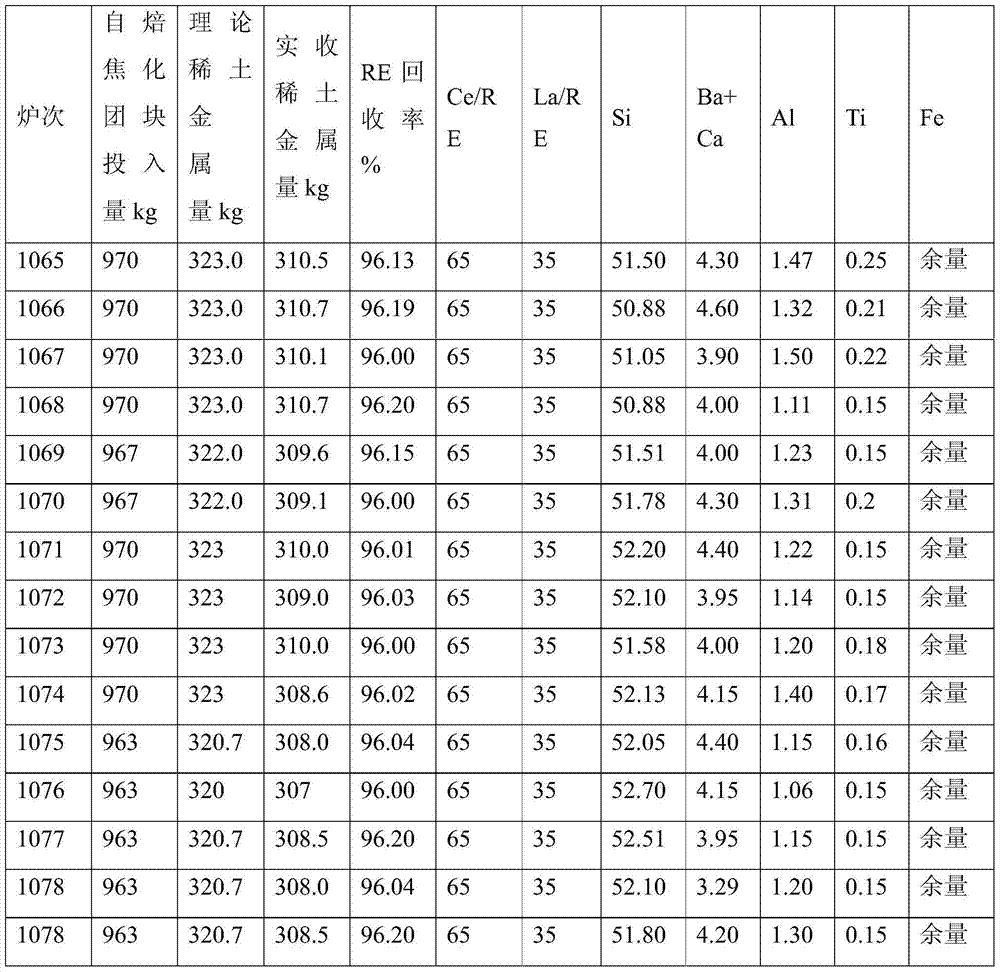

Embodiment 1

[0051] The technique of preparing rare earth silicon alloy (8000KVA submerged arc furnace to prepare SiRE30) with rare earth enrichment comprises the following steps:

[0052] (1) Preparation of coking agglomerates

[0053] The rare earth enrichment (the total mass of CeO and LaO in the rare earth enrichment is 40%, CeO / REO 65%; particle size≤5mm; BaO<5%, CaO<5%, TiO<1%), carbon powder, The vegetable starch is mixed and extruded to make agglomerates, and then the agglomerates are put into the submerged arc furnace, and the temperature of the surface layer is 450 ℃ ~ 950 ℃ in the submerged arc furnace, and the inherent physical and chemical characteristics of coal are used for self-baking coking. During the inner surface layer of the hot furnace and the sinking process, self-baking coking treatment becomes coking agglomerates;

[0054] (2) Preparation of rare earth silicon alloy

[0055] Add silica, gas coke and charcoal to the coking agglomerate, and smelt in submerged arc f...

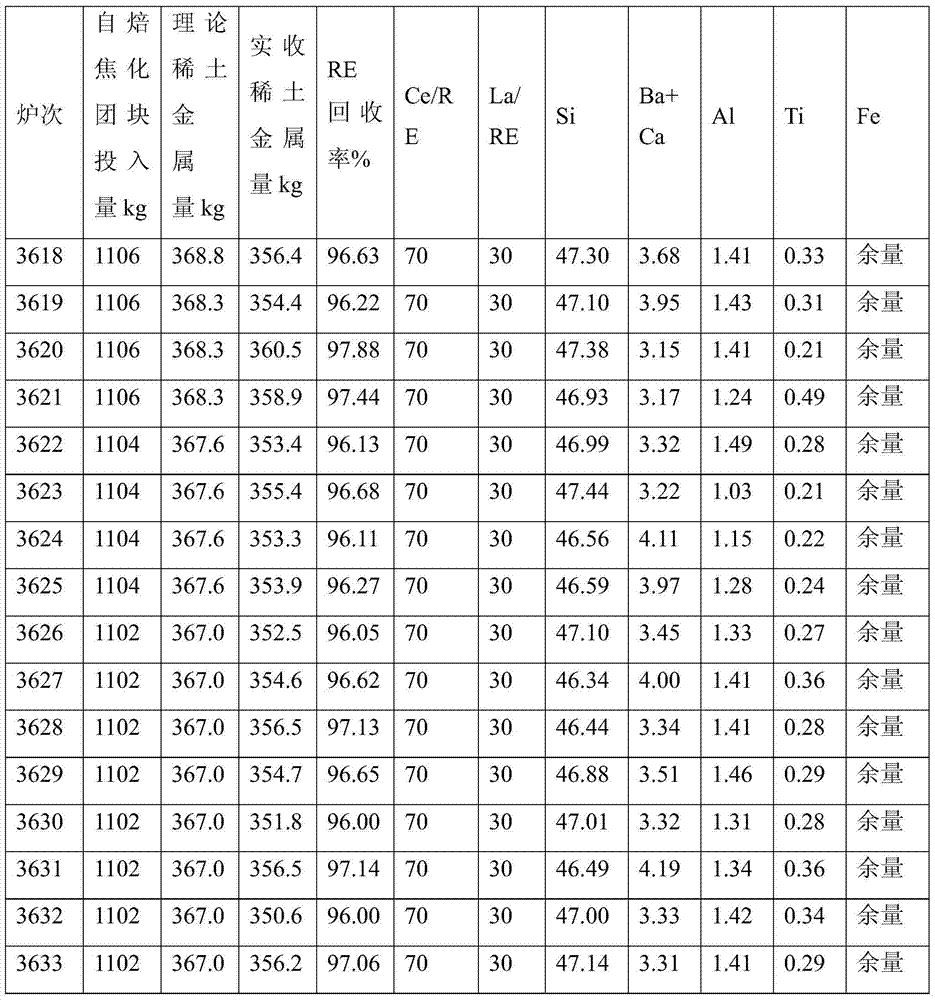

Embodiment 2

[0064] The process of preparing rare earth silicon alloy (8000KWA submerged arc furnace to prepare SiRE 35) with rare earth enrichment comprises the following steps:

[0065] (1) Preparation of coking agglomerates

[0066] Mix the rare earth enrichment (the total mass of CeO and LaO in the rare earth enrichment is 50%, particle size ≤ 5mm; BaO<5%, CaO<5%, TiO<1%), charcoal powder, plant starch, mix, squeeze Press into agglomerates, then put the agglomerates into submerged arc furnace, use the surface temperature of 450 ℃ ~ 950 ℃ in the submerged arc furnace, and the inherent physical and chemical characteristics of coal to carry out self-baking coking, in the submerged arc furnace During the feeding process, the self-baking coking process becomes coking agglomerates;

[0067] (2) Preparation of rare earth silicon alloy

[0068] Add silica, gas coke and charcoal to the coking agglomerate, and smelt in the submerged arc furnace. The power supply system conditions of the submer...

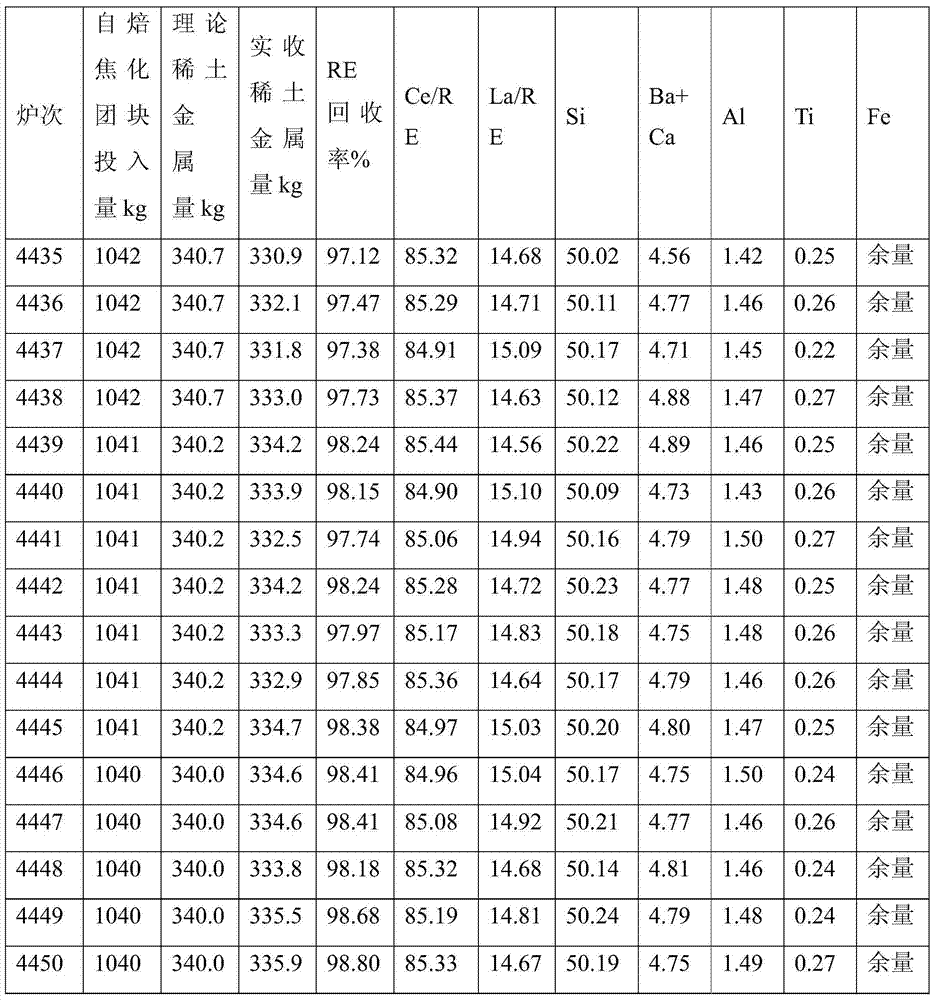

Embodiment 3

[0077] The technique of preparing rare earth silicon alloy (8000KWA submerged arc furnace to prepare SiRE40) with rare earth enrichment comprises the following steps:

[0078] (1) Preparation of coking agglomerates

[0079] Mix the rare earth enrichment (the total mass of CeO and LaO in the rare earth enrichment is 70%, particle size ≤ 5mm; BaO<5%, CaO<5%, TiO<1%), charcoal powder, plant starch, mix, squeeze Press into agglomerates, then put the agglomerates into submerged arc furnace, use the surface temperature of 450 ℃ ~ 950 ℃ in the submerged arc furnace, and the inherent physical and chemical characteristics of coal to carry out self-baking coking, in the submerged arc furnace During the feeding process, the self-baking coking process becomes coking agglomerates;

[0080] (2) Preparation of rare earth silicon alloy

[0081] Add silica, gas coke and charcoal to the coking agglomerate, and smelt in the submerged arc furnace. The power supply system conditions of the subme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com