A kind of flame-retardant titanium alloy with high vanadium content and preparation method thereof

A technology of flame-retardant titanium alloy and content, which is applied in the coating process and coating of metal materials, can solve the problems of complex alloy composition improvement process, difficult flame-retardant performance and processing performance, and large deformation resistance, and achieve the internal structure Excellent, pollution-free, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

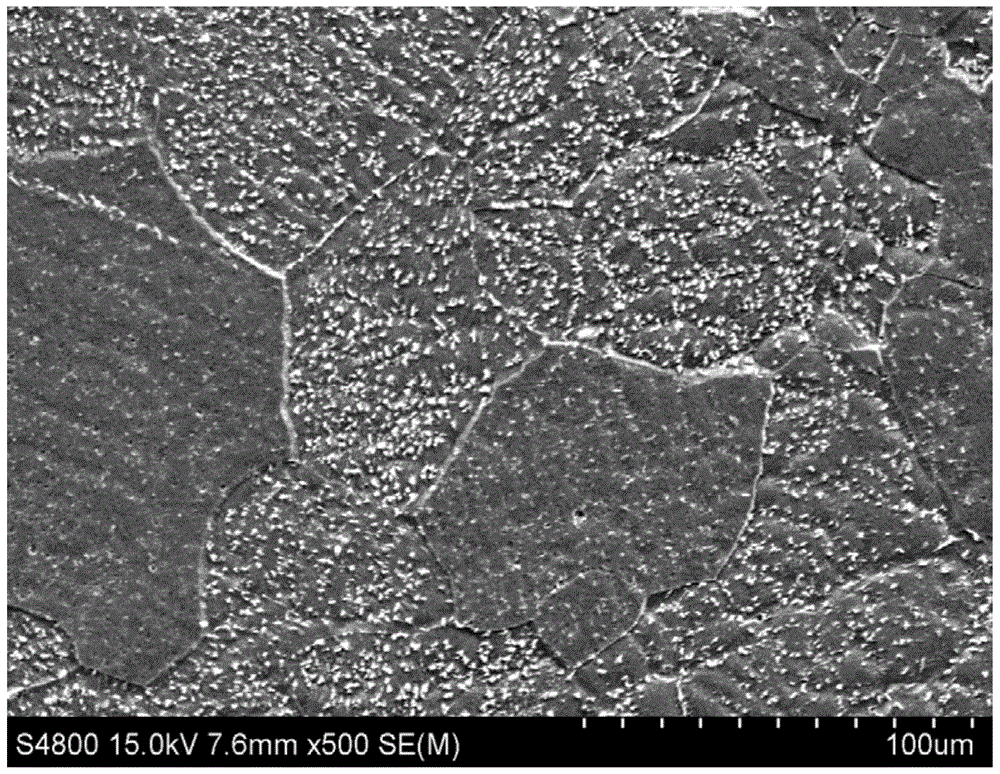

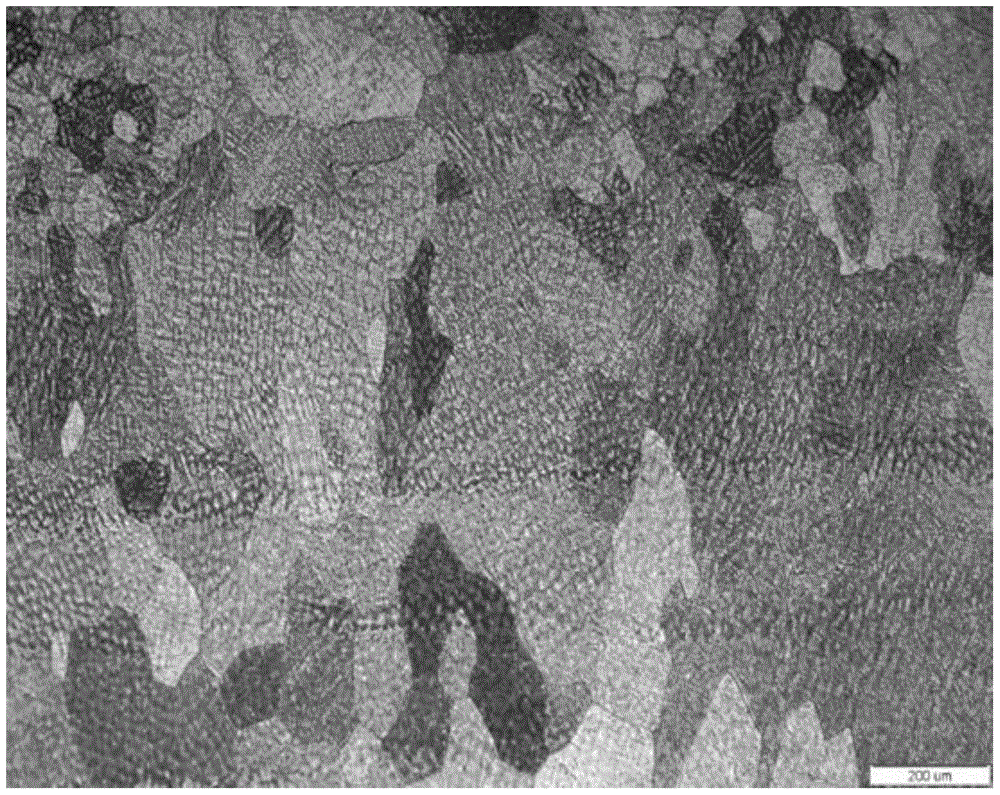

Embodiment 1

[0028] The flame-retardant titanium alloy with high vanadium content in this embodiment is composed of the following components by weight percentage: V 30%, Cr 15%, and the balance is Ti and unavoidable impurities.

[0029] The method for preparing the flame-retardant titanium alloy with high vanadium content in this embodiment is:

[0030] Step 1. Mix titanium powder, vanadium powder and chromium powder to obtain a mixed powder, and then dry the mixed powder at 120°C for 1.5 hours, and then grind and mix the dried mixed powder evenly to obtain a powder; The average particle size of the titanium powder is 131.4 μm, the average particle size of the vanadium powder is 58.5 μm, the average particle size of the chromium powder is 75 μm, and the mass purity of the titanium powder, vanadium powder and chromium powder is not less than 99.9%, The oxygen content of the titanium powder, vanadium powder and chromium powder is not more than 0.1wt%;

[0031] Step 2. Use laser cladding deposition...

Embodiment 2

[0034] The flame-retardant titanium alloy with high vanadium content in this embodiment is composed of the following components by weight percentage: V 27%, Cr 15%, and the balance is Ti and unavoidable impurities.

[0035] The method for preparing the flame-retardant titanium alloy with high vanadium content in this embodiment is:

[0036] Step 1. Mix titanium powder, vanadium powder and chromium powder to obtain a mixed powder, and then dry the mixed powder at 110°C for 2 hours, and then grind and mix the dried mixed powder evenly to obtain a powder; The average particle size of the titanium powder is 150 μm, the average particle size of the vanadium powder is 50 μm, the average particle size of the chromium powder is 89 μm, and the mass purity of the titanium powder, vanadium powder and chromium powder is not less than 99.9%. The oxygen content of powder, vanadium powder and chromium powder is not more than 0.1wt%;

[0037] Step 2. Use laser cladding deposition to deposit the pow...

Embodiment 3

[0040] The flame-retardant titanium alloy with high vanadium content in this embodiment is composed of the following components by weight percentage: V 35%, Cr 15%, and the balance is Ti and inevitable impurities.

[0041] The method for preparing the flame-retardant titanium alloy with high vanadium content in this embodiment is:

[0042] Step 1. Mix titanium powder, vanadium powder and chromium powder to obtain mixed powder, and then dry the mixed powder at 130°C for 1 hour, and then grind and mix the dried mixed powder uniformly to obtain a powder; The average particle size of the titanium powder is 75 μm, the average particle size of the vanadium powder is 61.7 μm, the average particle size of the chromium powder is 50 μm, and the mass purity of the titanium powder, vanadium powder and chromium powder is not less than 99.9%. The oxygen content of titanium powder, vanadium powder and chromium powder is not more than 0.1wt%;

[0043] Step 2. Use laser cladding deposition to deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com