Heat-preservation moisture-preservation life-preserving device for tunnel lining concrete and construction method thereof

A construction method and concrete technology, applied in tunnel lining, tunnel, shaft lining and other directions, can solve the problems of maintenance operation, serious heat release of cement hydration, and excessive concrete temperature difference, and achieve convenient construction, convenient and flexible use, and applicable scope. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

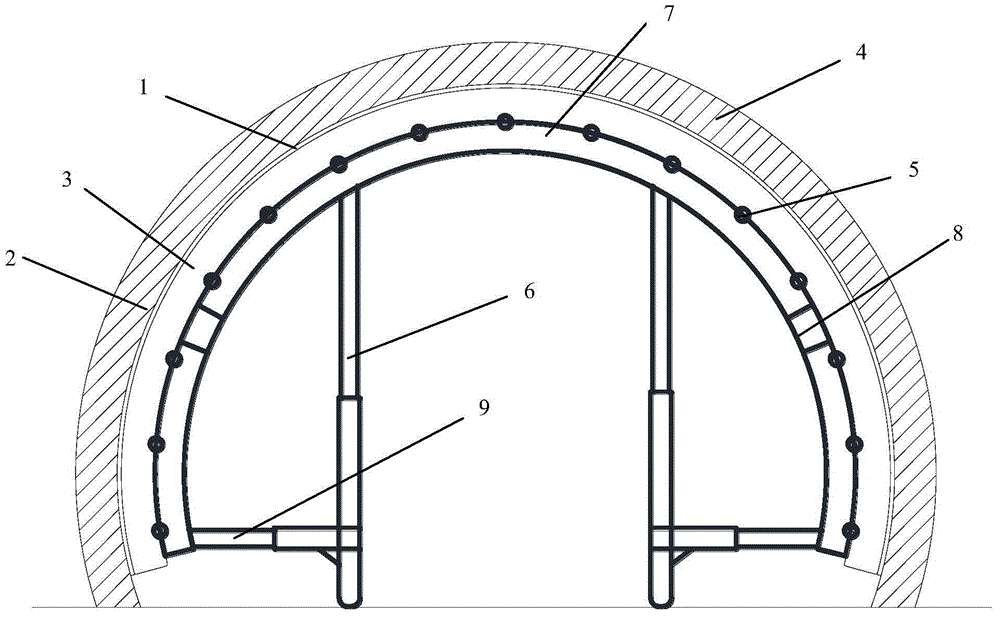

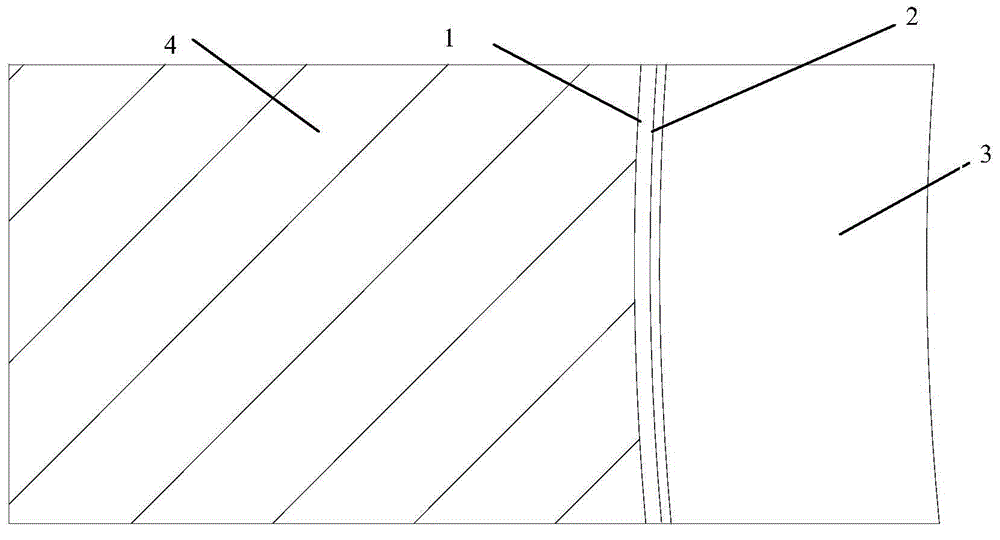

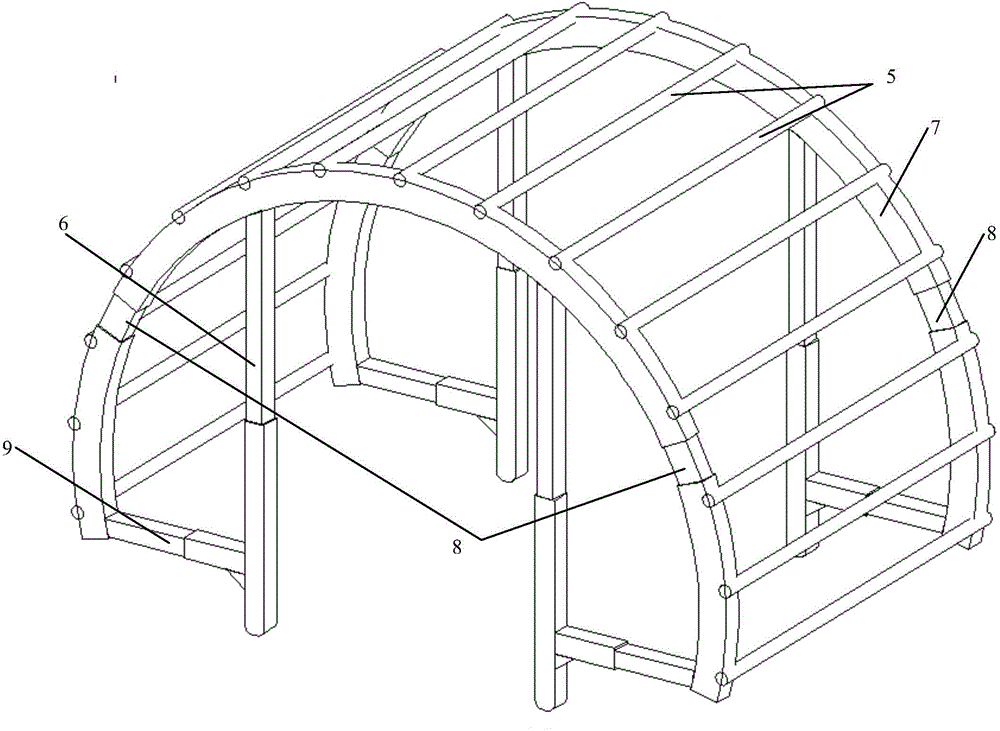

[0044] Such as Figure 1 ~ Figure 3 As shown, the present invention includes a moisturizing layer 1, an electric heating layer 2, a thermal insulation layer 3 and a health care trolley, and the health care trolley is composed of a steel pipe 5, a vertical support bracket 6, a steel frame 7, a connecting rod 8 and a lateral support bracket 9 Composition, the vertical support bracket 6, the lateral support bracket 9 and the connecting rod 8 can be stretched, and the range of action of the steel frame 7 is adjusted, and the steel pipe 5 is welded on the steel frame 7.

[0045]Shrink the support vertical support bracket 6, lateral support bracket 9 and connecting rod 8 of the health care trolley, reduce the height of the health care trolley, and leave a certain working space between the steel frame 7 and the secondary lining 4. The top of the steel pipe 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com