Lamp high in cooling efficiency and good in safety performance

A technology with safety performance and heat dissipation efficiency, applied in the safety devices of lighting devices, lighting and heating equipment, cooling/heating devices of lighting devices, etc. Low and other problems, to achieve the effect of high heat dissipation performance and thermal conductivity, good thermal conductivity and heat dissipation performance, and ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

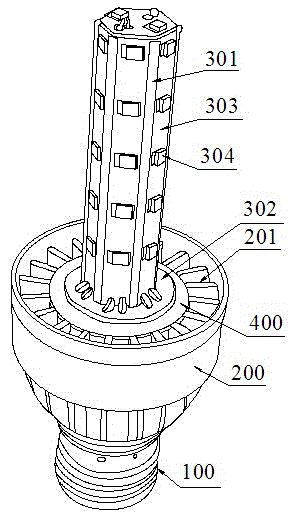

[0012] refer to figure 1 , an embodiment of a lamp with high heat dissipation efficiency and good safety performance of the present invention is proposed, which includes a lamp cap nut 100, a lamp holder 200 connected and fixed on the upper end of the lamp cap nut 100 with a hollow cavity inside, and fixed on The illuminant structure at the upper end of the lamp holder 200 , the light-transmitting cover that is fixedly connected with the lamp holder 200 and covered outside the illuminant structure, also includes a driving device accommodated in the hollow cavity.

[0013] The illuminant structure includes a light source installation column 301 fixed on the upper end of the lamp holder 200, an LED light source structure closely attached to the side and top surface of the light source installation column 301, and an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com