Chilled water storage device

A technology of water storage and cold storage, applied in heating methods, lighting and heating equipment, applications, etc., can solve the problems of difficult operation control, low space utilization rate, and high membrane requirements, so as to reduce invalid space, increase water storage temperature difference, Effect of increasing cold storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in combination with specific embodiments.

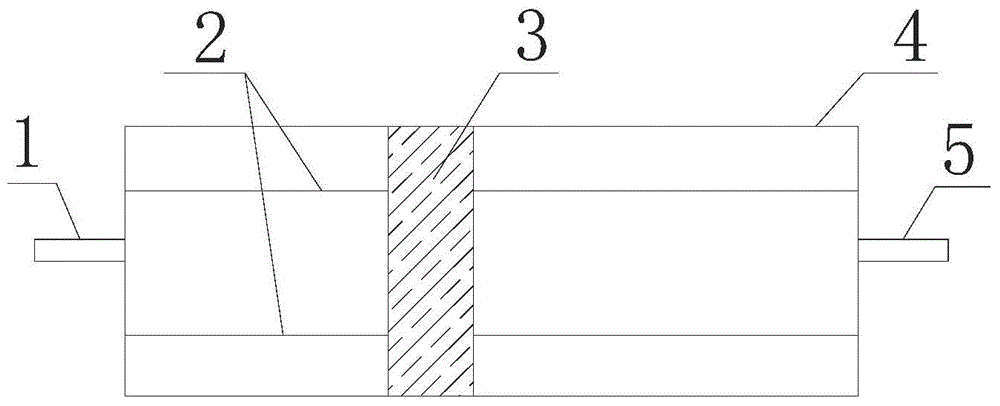

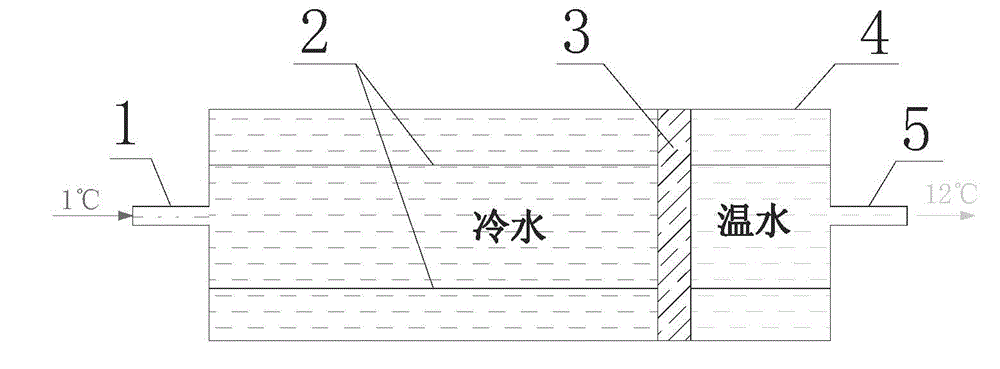

[0020] The water cold storage device of the present invention, such as figure 1 As shown, it includes cold storage water inlet / cooling water outlet 1, guide slide bar 2, partition plate 3, cold storage container 4 and cold storage water outlet / cooling water inlet 5.

[0021] The cold storage container 4 is a closed structure, the guide slider 2 is fixed in the cold storage container 4, the partition plate 3 is set on the guide slider 2, and can slide along the guide slider 2, and the cold storage container 4 is divided into two completely isolated parts , one side stores cold water, one side stores warm water, a cold storage water inlet / cooling water outlet 1 is set on the container wall on the cold water side, and a cold storage water outlet / cooling water inlet 5 is set on the container wall on the warm water side.

[0022] The cold storage water inlet / cooling outlet 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com