Path planning method of surface array salient point on-demand jet printing control system

A jet printing and control system technology, applied in the direction of digital control, electrical program control, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

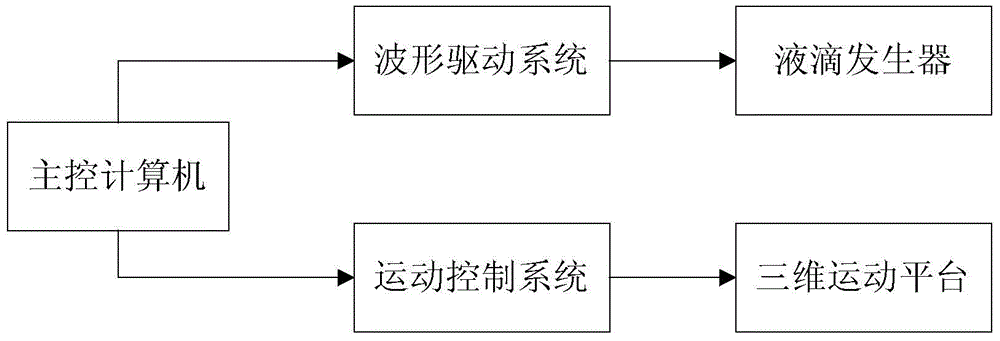

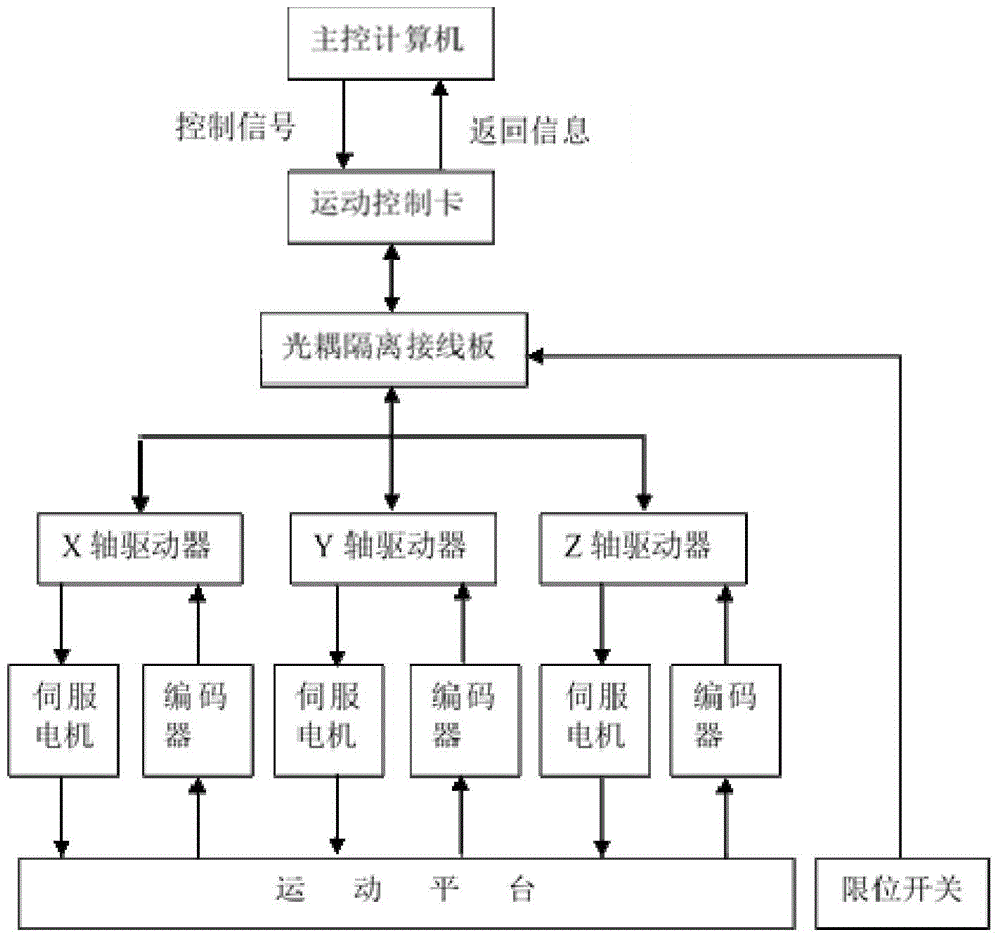

[0034] This embodiment also provides an area array bump printing system, the area array bump printing system includes a main control computer, a waveform drive system, a droplet generator, a motion control system and a three-dimensional motion platform;

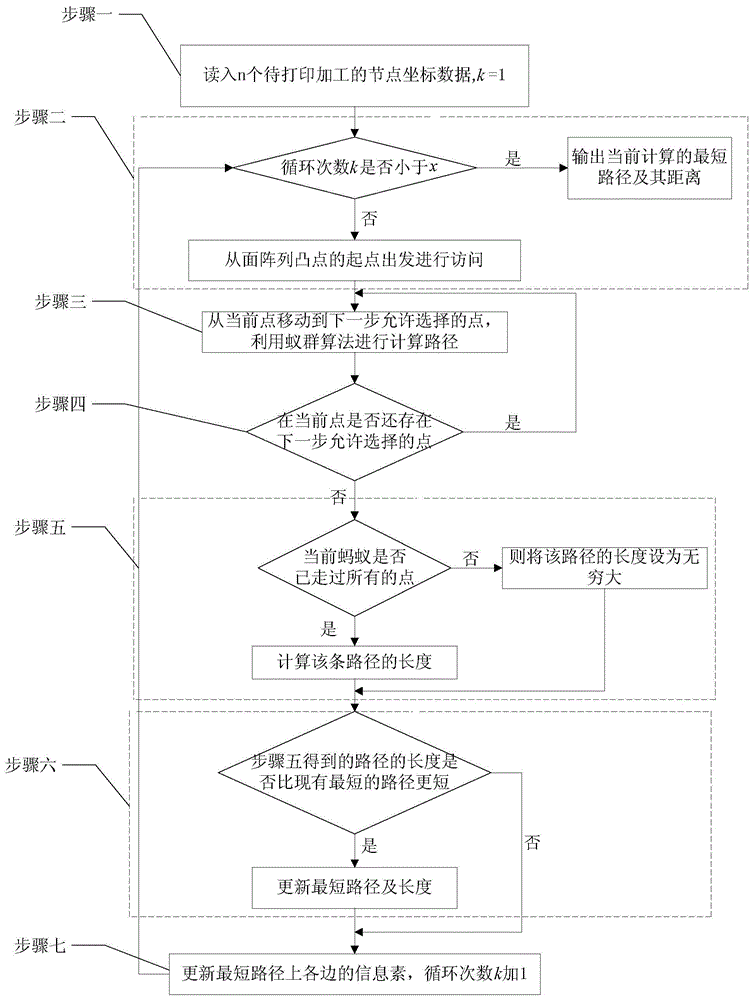

[0035] After the surface array bump drop-on-demand printing program in the main control computer starts, it will first read all the data in the user coordinate file, perform path planning processing to form a new coordinate file, and then read the data in the new coordinate file sequentially Point the coordinates and drive the three-dimensional motion platform to move through the motion control system to judge whether it has reached the end point, and end the program after reaching the end point, otherwise it will move according to the difference of the coordinates. At the same time, the droplet generator is controlled by the waveform drive system, and the coordinated control of the two systems is carried out to realize the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com