Full-gluing dynamic balancing gyro motor

A gyro motor and gluing technology, applied in the field of inertial components, can solve the problems of low assembly efficiency, larger dynamic balance of gyro motor, easy loosening of screws, etc., and achieve the effect of good pressure-resistant sealing performance and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

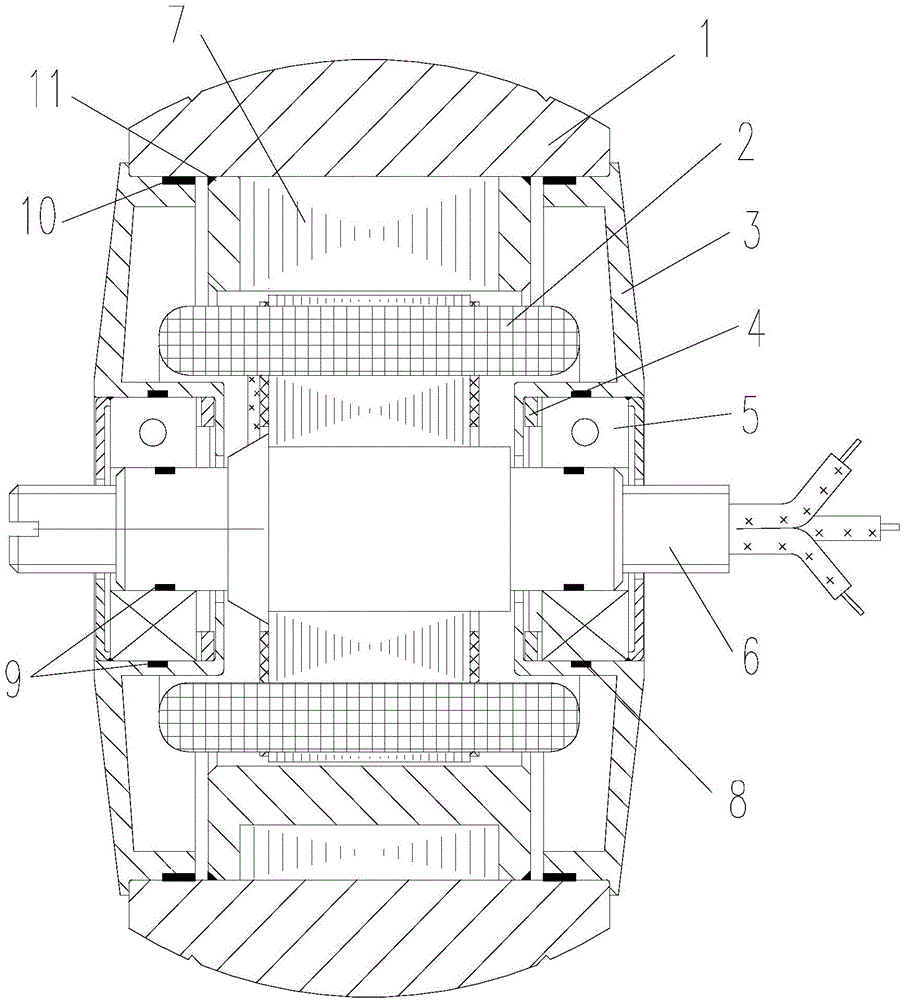

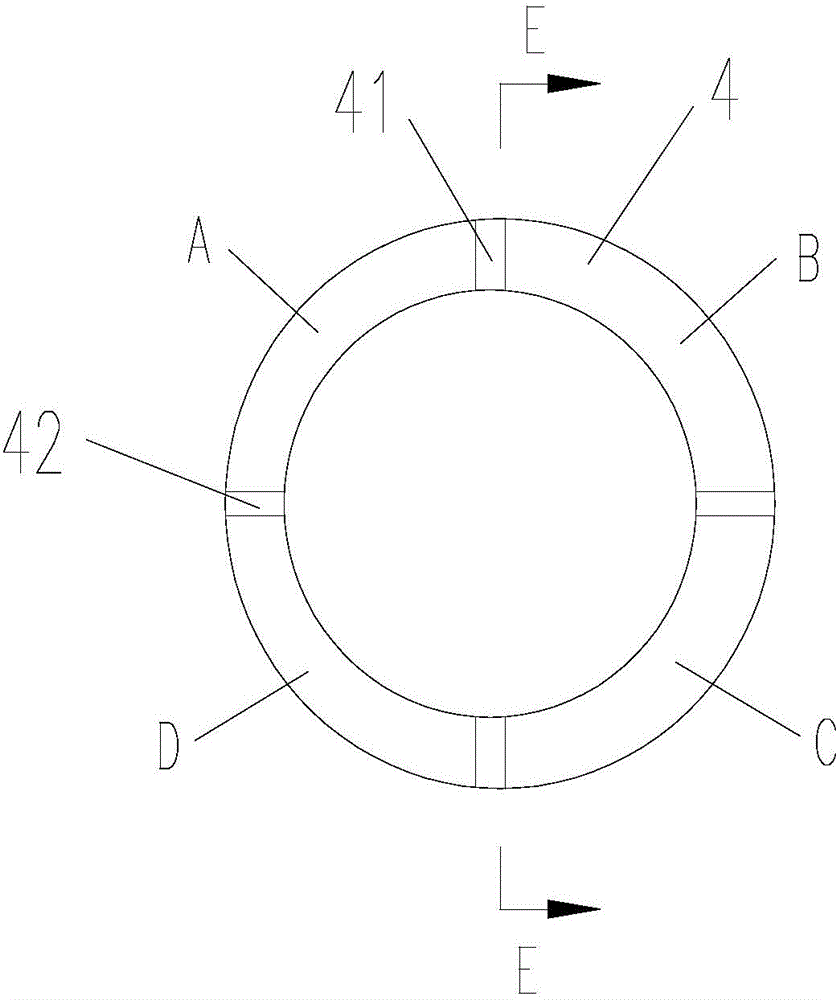

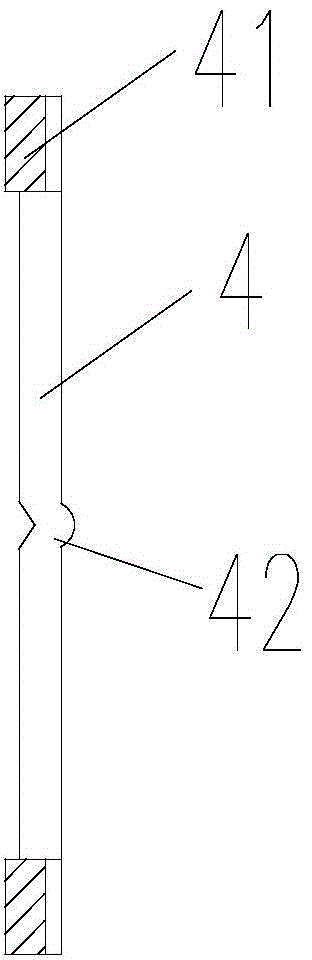

[0018] Attached below Figure 1-3 An embodiment of the present invention is described.

[0019] The fully glued dynamic balance gyro motor has a motor rotor 1, a motor stator assembly 2, an end cover 3 and a motor stator shaft 6, and the motor rotor assembly 1 and the end cover 3 are supported on the motor stator shaft 6 through a high-speed bearing 5, so The motor stator assembly 2 is interference fit with the motor stator shaft 6. After the interference fit between the squirrel cage 7 and the motor rotor 1, the end cover 3 and the high-speed bearing 5 at both ends are set on the motor stator shaft 2 and three-phase alternating current is applied for high-speed rotation. ; The inner ring of the high-speed bearing 5 and the stator shaft 6 of the motor are in clearance fit, and the anti-creep glue is coated between them, and the joint between the outer ring of the high-speed bearing 5 and the end cover 3 is also in a clearance fit, and the two are also coated Anti-creep adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com