Double-salient-pole permanent magnet linear motor and motor module group using same

A technology of permanent magnet linear motor and doubly salient poles, which is applied in the direction of electric components, electrical components, electromechanical devices, etc. It can solve the problems of permanent magnet magnetic flux leakage and weakening motor output capacity, etc., and achieves large thrust, simple and reliable structure, and thrust fluctuation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

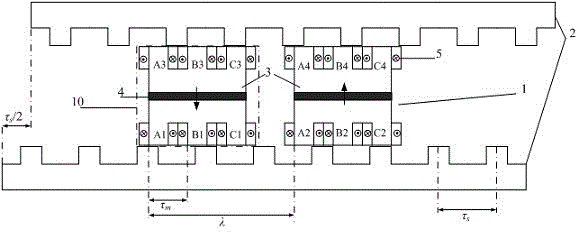

[0012] In order to illustrate the structural features and operating principles of the present invention, a three-phase motor is taken as an example below.

[0013] Such as figure 1 As shown, the doubly salient permanent magnet linear motor provided by the present invention ( τ m =8 / 12* τ s ), including a mover 1 and a stator 2, both of which are salient pole structures with an air gap between them. There are neither permanent magnets nor armature windings on the stator 2, but are only composed of magnetically permeable materials. The upper and lower stators 2 are staggered by half the stator pole pitch ( τ s / 2) displacement. The mover 1 includes two mover modules 10. The relative displacement between the two mover modules 10 is lambda = 2.5* τ s . The mover module 10 includes an iron core 3 , a permanent magnet 4 and an armature winding 5 . A permanent magnet 4 is sandwiched between the iron cores 3 of the mover module 10 . The magnetization direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com