Sterilizing pot for preparing cans

A sterilizing pot and canning technology, which is applied in application, food science, food preservation, etc., can solve the problems of uneven distribution of high-temperature steam and poor sterilization effect, and achieve the effects of simple structure, good sterilization effect and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a limitation of the present invention.

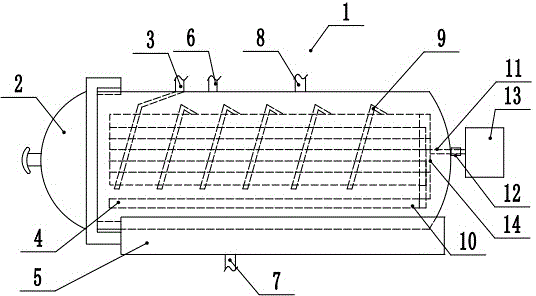

[0015] The reference signs in the figure are: pot body 1, pot cover 2, steam inlet pipe 3, slide rail 4, support plate 5, exhaust pipe 6, drain pipe 7, vent pipe 8, steam spray pipe 9, moving frame 10 , moving arm 11, sleeve 12, motor 13, fixed plate 14.

[0016] Such as figure 1 As shown, a sterilizer for preparing cans includes a pot cover 2, a pot body 1, and a steam inlet pipe 3 communicated with the pot body 1, a steam exhaust pipe 6, a drain pipe 7, a compressed air inlet pipe and an air discharge pipe 8 , also includes a moving frame 10 screwed in the pot body 1, two moving arms 11 screwed to the moving frame 10, and a motor 13 connected to the moving arms 11 through a rigid coupling. The moving arm 11 passes through the side wall of the pot body 1, and the joint between the moving arm 11 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com