Clamp for position changing rocker arm machining

A fixture and pallet technology, which is applied in the field of fixtures for transposition rocker arm processing, can solve the problems of complex structure, high cost of machining equipment, and obvious vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

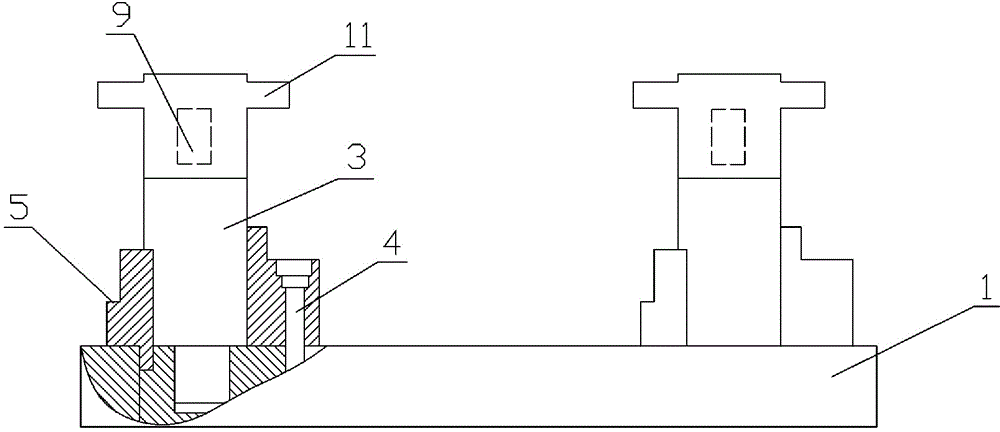

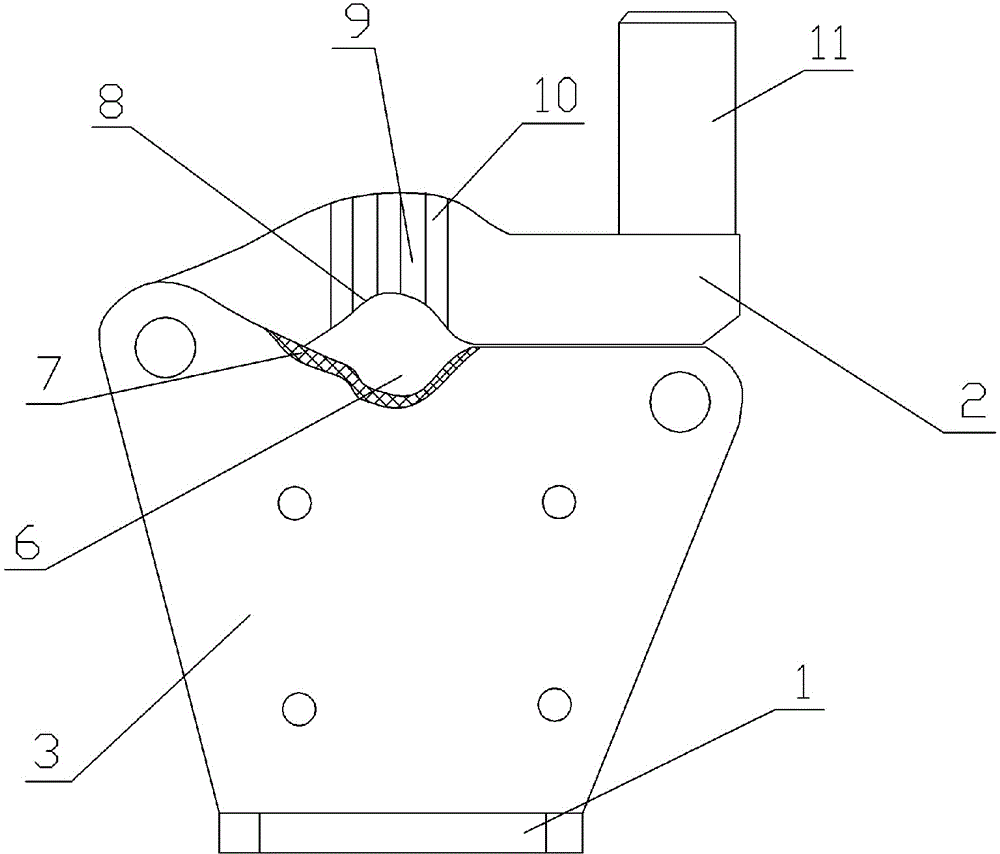

[0013] The reference signs in the drawings of the specification include: machine base 1, pressure plate 2, pallet 3, fixing screw 4, clamping step 5, groove 6, flexible rubber 7, arc 8, drill sleeve 9, drilling 10, Press the handle 11.

[0014] Such as figure 1 , figure 2 As shown, the jig for processing the transposition rocker arm includes a base 1, a pressing plate 2 and a pallet 3 fixed on the base 1. The pallet 3 is fixed on the base 1 in a group of two, and the pallet 3 passes The fixing screw 4 is connected to the machine base 1. The outer surface of the pallet 3 is provided with an inwardly concave clamping step 5, the pressure plate 2 is hinged to the top end of the pallet 3 by a pin, and the other end of the pallet 3 is provided with A platform that matches the pressing surface of the pressure plate 2, and the top of the pallet 3 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com