Adjustable transmission rack for feeding of cutter

An adjustable and cutting machine technology, applied in shearing devices, accessories of shearing machines, metal processing equipment, etc., can solve the problems of increased inconvenience, different steel specifications, and inability to adjust the height of the roller shaft of the conveyor. Improve convenience and solve the effect of loud noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

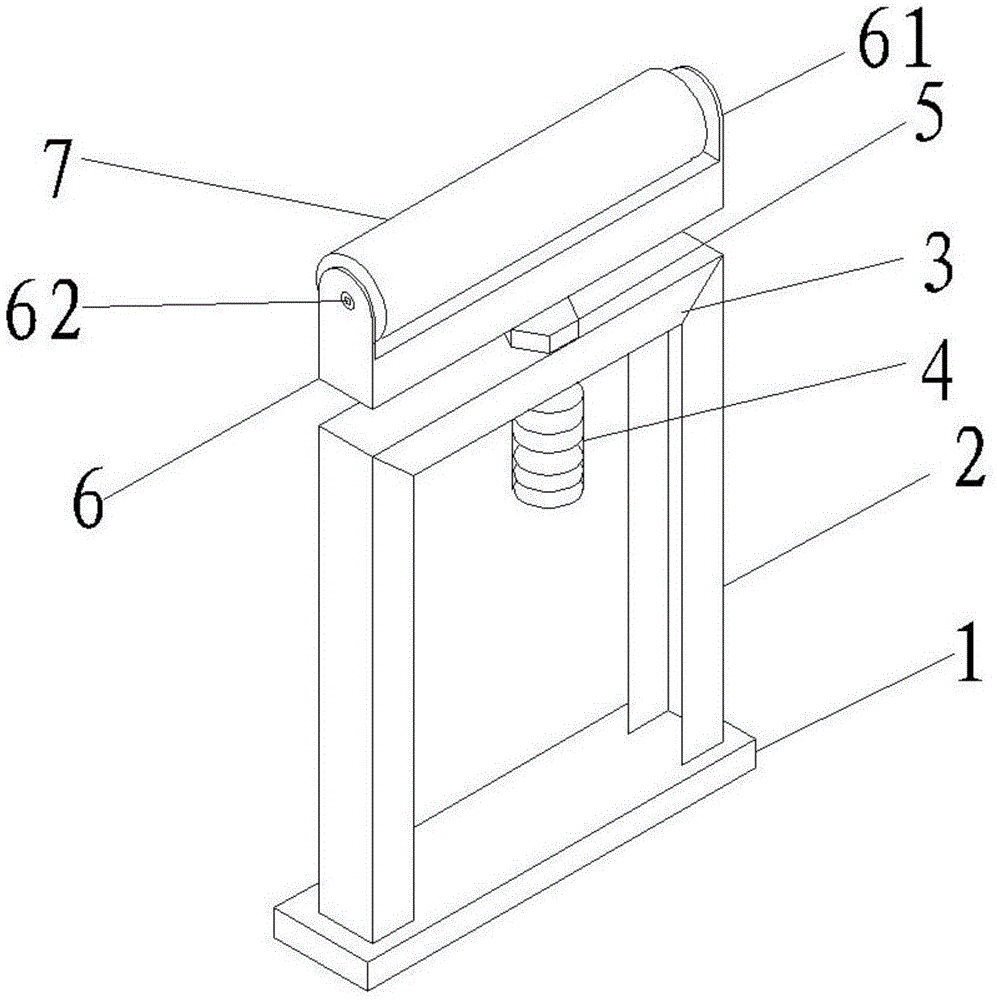

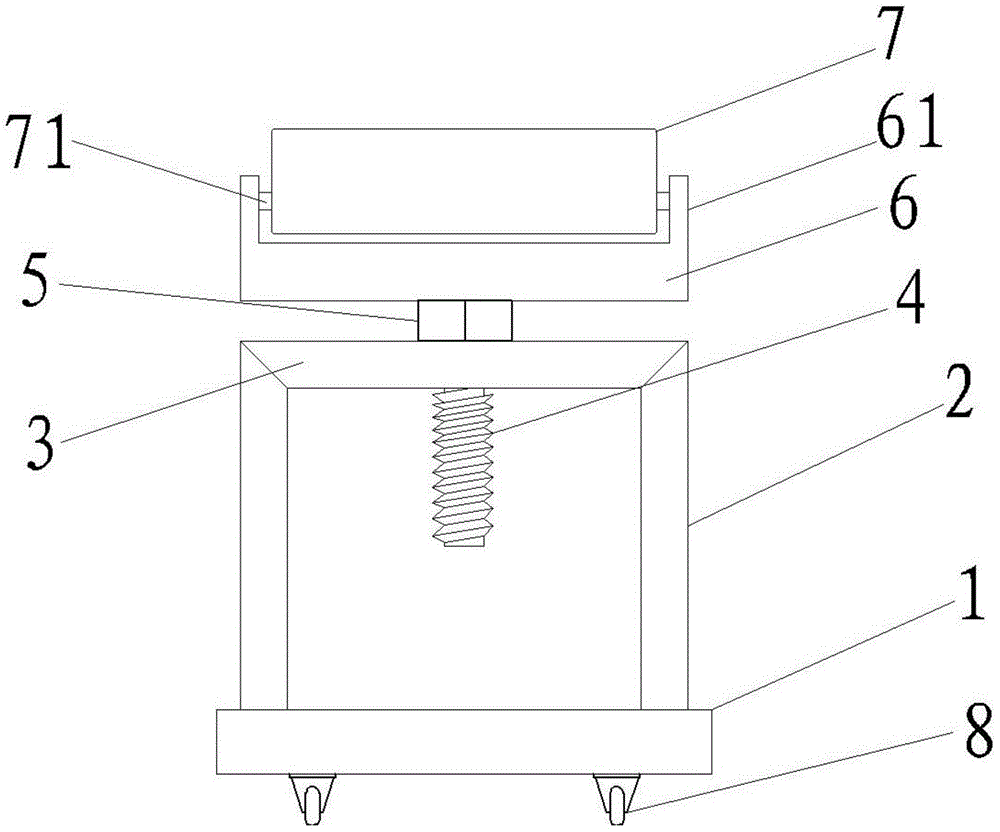

[0017] see Figure 1-2 , an adjustable transfer frame for cutting machine feeding, which has:

[0018] Base 1, casters 8 are fixed on both sides of the bottom surface of the base 1, and the base 1 is convenient to move through the casters 8;

[0019] The supporting body, the supporting body includes vertical beams 2 arranged perpendicular to the base, the vertical beams 2 are arranged on both sides of the side of the base 1, and can be fixed with the base 1 by welding, and a cross beam 3 is connected between the tops of the vertical beams 2, and the cross beams The middle part of 3 has the through hole that runs through beam 3.

[0020] Lifting assembly, the lifting assembly includes a frame body 6, lugs 61 are respectively formed on both sides of the frame body 6, a roller shaft 7 is fixed between the lugs 61, a screw rod 4 is vertically fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com