Numerical control machine tool processing method of workpiece with bidirectional deflection space angles

A technology of deflection space and processing method, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as difficulty in ensuring workpiece processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

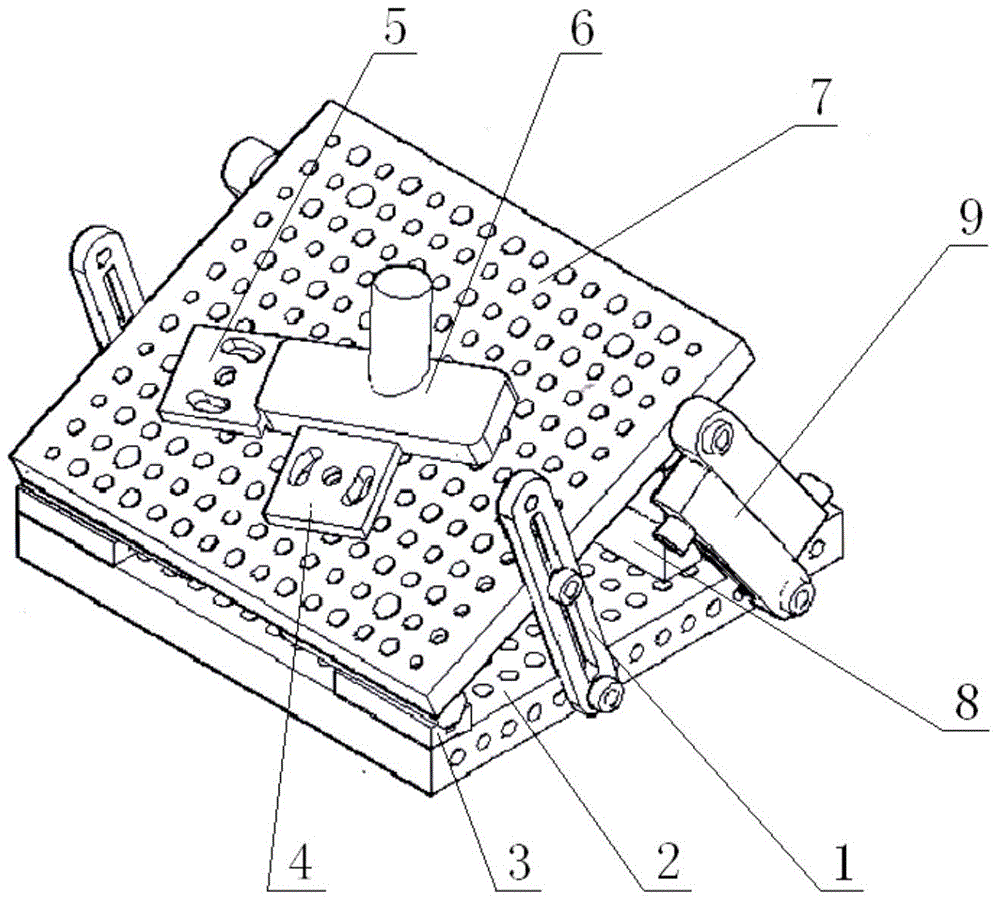

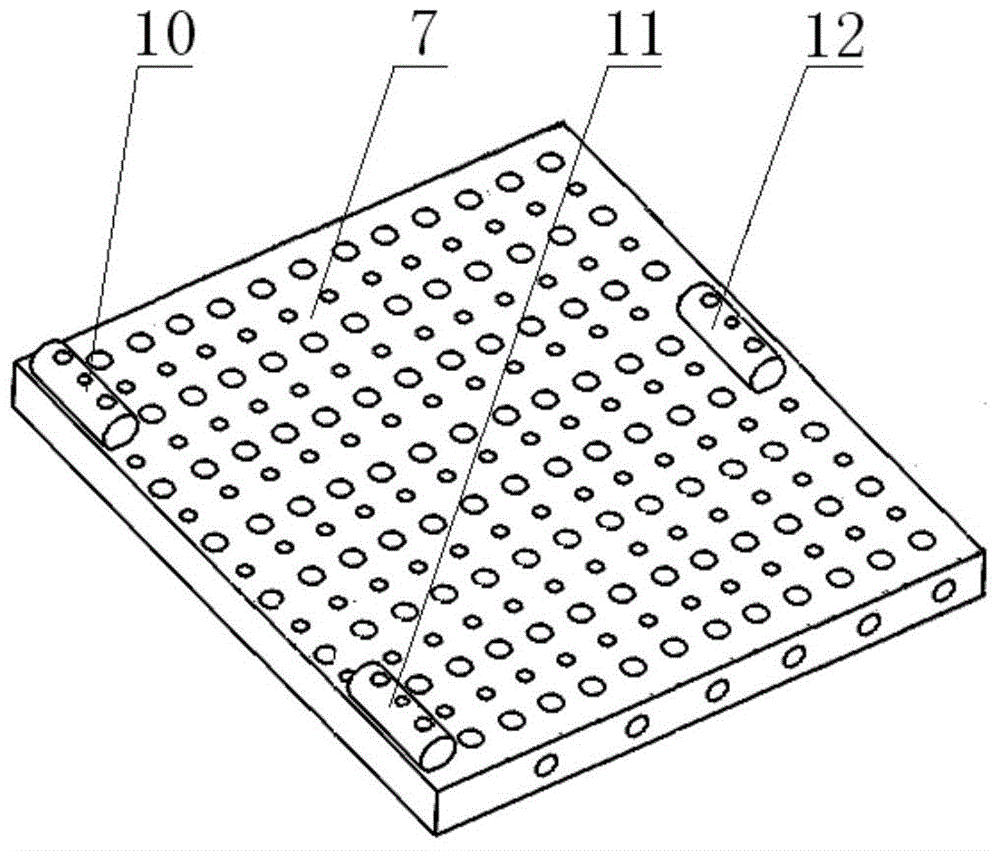

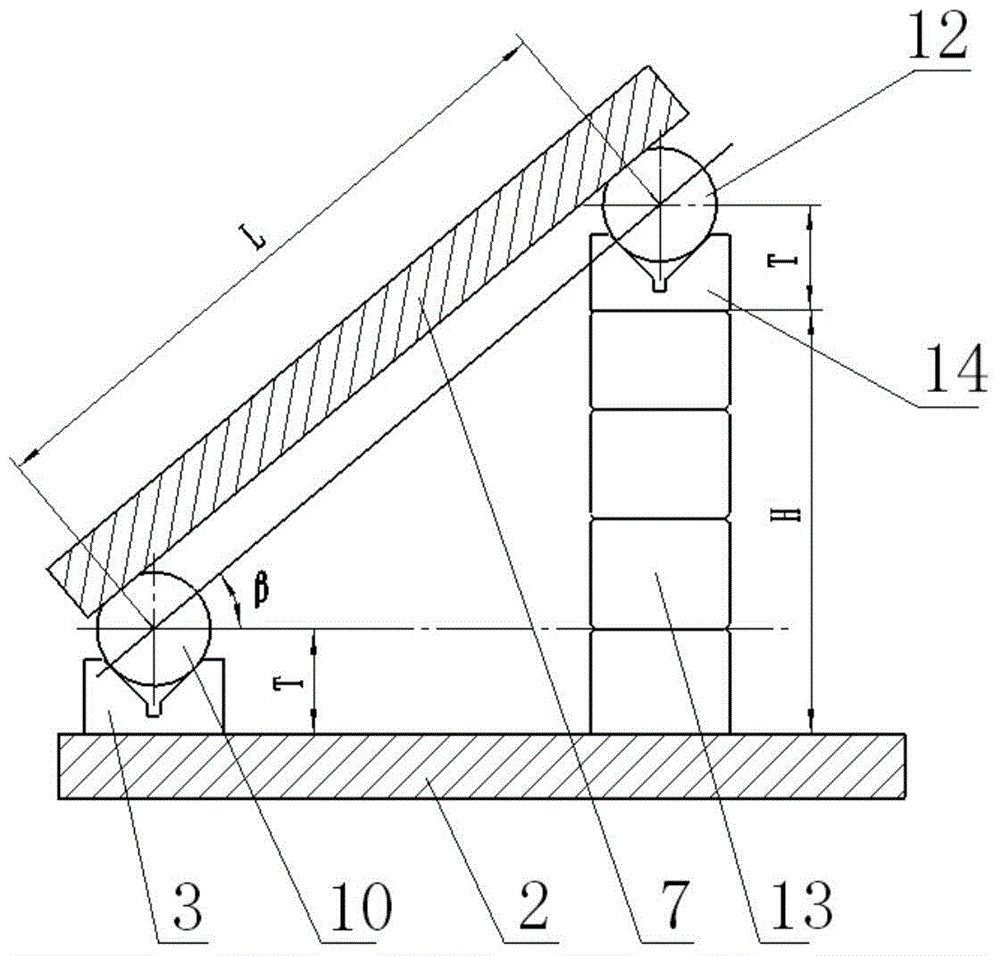

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the angle table includes a lower base plate 2, an upper base plate 7, a first connecting plate 1, a second connecting plate 9 and a support 8, and the support 8 is vertically fixed on the lower base plate 2, and the lower base plate 2 is close to Two identical low-position V-shaped support blocks 3 whose centerlines coincide are arranged on one side. The support 8 is composed of a rectangular support element 13 and a high-position V-shaped support block 14. The high-position V-shaped support block 14 has the same structure as the low-position V-shaped support block 3. And the center line of the high V-shaped support block 14 is parallel to the center lines of the two low V-shaped support blocks 3 . There are bolt holes and pin holes arranged at intervals in a matrix on the upper base plate 7, and a first edge trimming shaft 10, a second edge trimming shaft 11 and a third edge trimming shaft 12 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com